Down jacket fabric with anti-static function and manufacturing process thereof

A down jacket fabric and production process technology, applied in the field of down jacket fabrics, can solve the problems of inconvenient cleaning, poor anti-static, waterproof and oil-resistant effects, and the fabric is easily stained with stains, so as to enhance the waterproof and anti-static performance, and enhance the breathable and anti-static performance. , the effect of enhancing security and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The invention provides a down jacket fabric with antistatic function, comprising: 844.0g of nylon taffeta, 44.0g of polyurethane, 44.0g of composite modifier, and 68.0g of polytetrafluoroethylene; the composite modified Agents include: 8.624g of polyimide fiber, 8.624g of nano-silver, 6.336g of nano-titanium dioxide, 6.424g of perfluorohexyl ethyl methacrylate, 1.584g of n-butyl acrylate, 0.704g of methyl Acrylic acid-3-chloro-2-hydroxypropyl ester, vinyl chloride of 1.584g, chitosan of 10.208g;

[0028] A production process of a down jacket fabric with antistatic function, the specific production steps are as follows:

[0029]Step 1: According to the above weight ratio, weigh base cloth, polyurethane, polytetrafluoroethylene, polyimide fiber, nano-silver, nano-titanium dioxide, perfluorohexyl ethyl methacrylate, n-butyl acrylate, 3-chloro-2-hydroxypropyl methacrylate, vinyl chloride, chitosan;

[0030] Step 2: mix the polyimide fiber, nano-silver and nano-titanium di...

Embodiment 2

[0038] Different from Example 1, it includes: 854.0g nylon taffeta, 58.0g polyurethane, 54.0g composite modifier, 34.0g polytetrafluoroethylene; the composite modifier includes: 10.908g Polyimide fiber, 11.016g of nano-silver, 8.532g of nano-titanium dioxide, 8.424g of perfluorohexylethyl methacrylate, 2.484g of n-butyl acrylate, 1.404g of methacrylic acid-3-chloro- 2-hydroxypropyl ester, 2.592g of vinyl chloride, 8.64g of chitosan.

Embodiment 3

[0040] All different from Example 1-2, including: 849.0g of nylon taffeta, 51.0g of polyurethane, 49.0g of composite modifier, 51.0g of polytetrafluoroethylene; said composite modifier includes: 9.751g of polyimide fiber, 9.751g of nano silver, 7.399g of nano titanium dioxide, 7.399g of perfluorohexyl ethyl methacrylate, 2.009g of n-butyl acrylate, 1.029g of methacrylic acid-3 - Chloro-2-hydroxypropyl ester, 2.058g of vinyl chloride, 9.604g of chitosan.

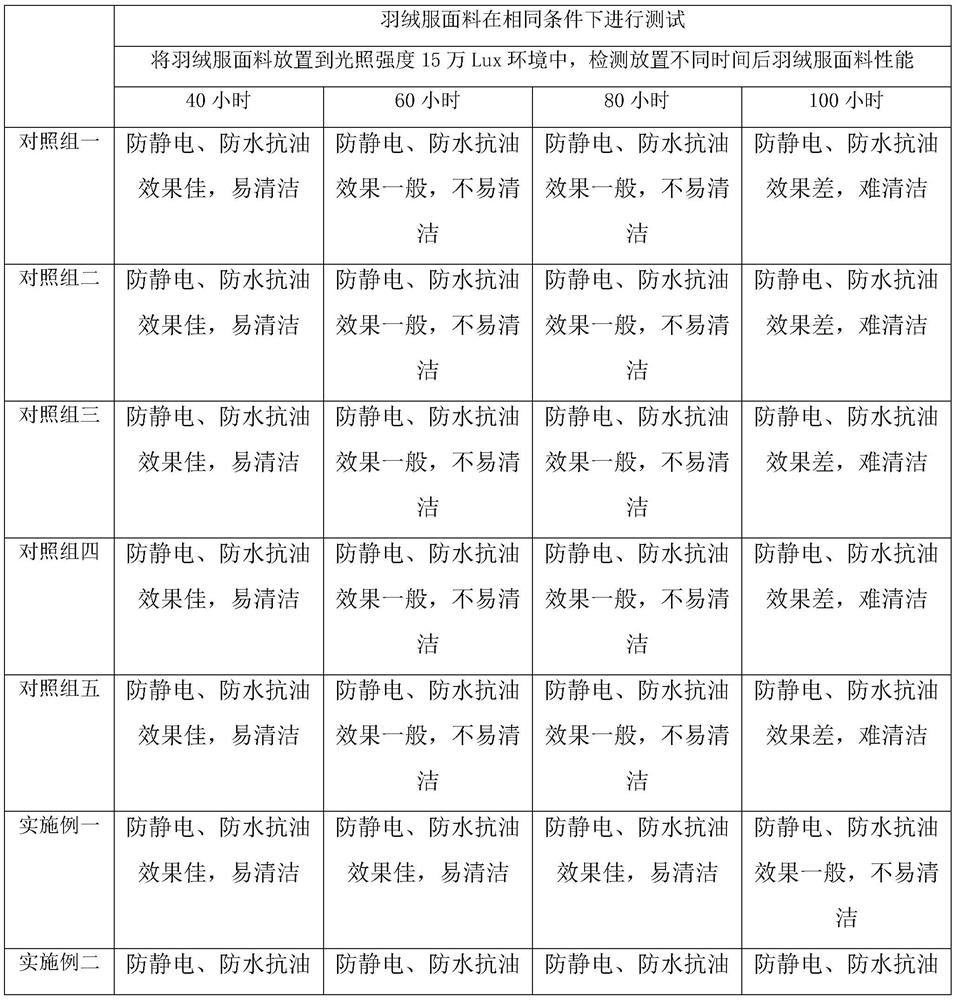

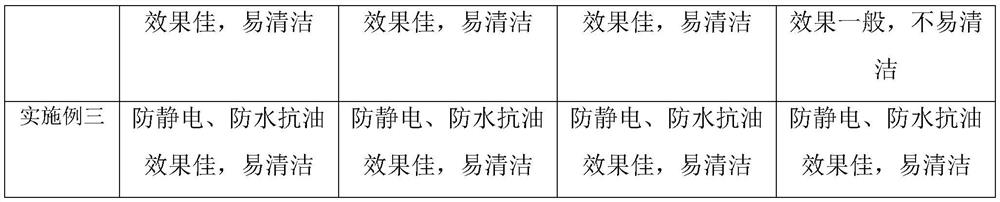

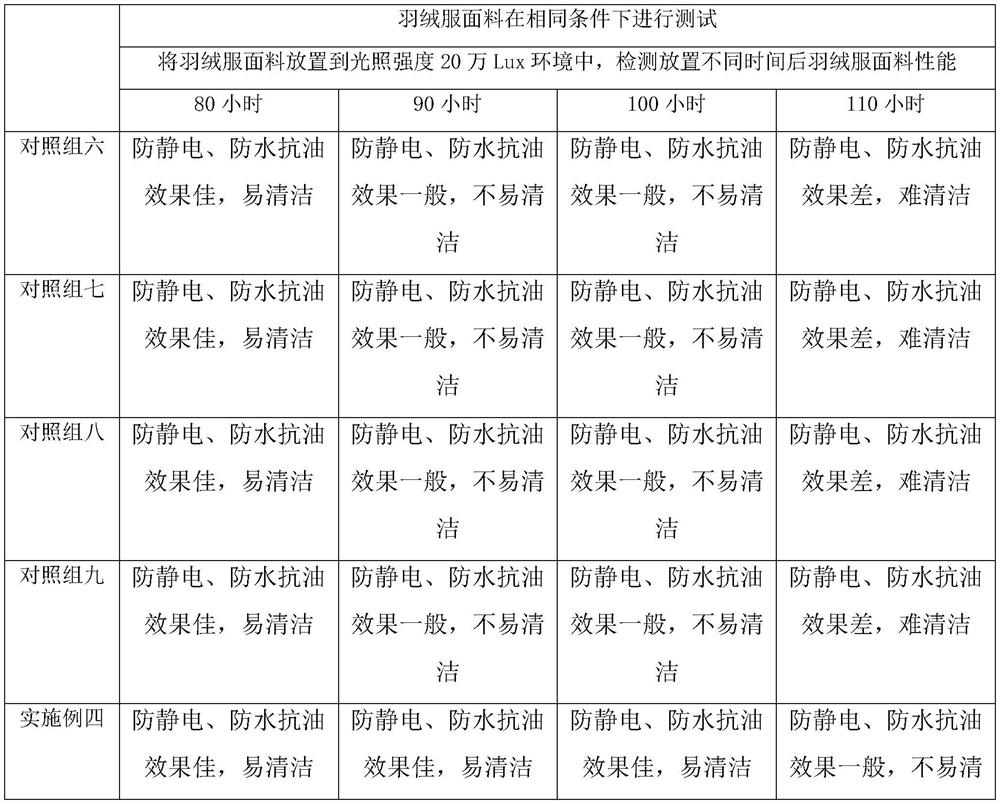

[0041] Get the down jacket fabric with antistatic function prepared by above-mentioned embodiment 1-3 and the down jacket fabric of control group one, the down jacket fabric of control group two, the down jacket fabric of control group three, the down jacket fabric of control group four and the control group The down jacket fabric of five, the down jacket fabric of control group one compared with embodiment three without nano-silver, the down jacket fabric of control group two compared with embodiment three without nano-titan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com