90 DEG C flexible polyvinyl chloride elastomer sheath material

A soft polyvinyl chloride and polyvinyl chloride resin technology, applied in the field of 90 ℃ soft polyvinyl chloride elastomer sheath material, can solve the problem of softness and aging resistance, poor durability, low molecular plasticizer migration, Easy to plastic deformation and other problems, to achieve the effect of excellent migration resistance, good processing performance and high cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

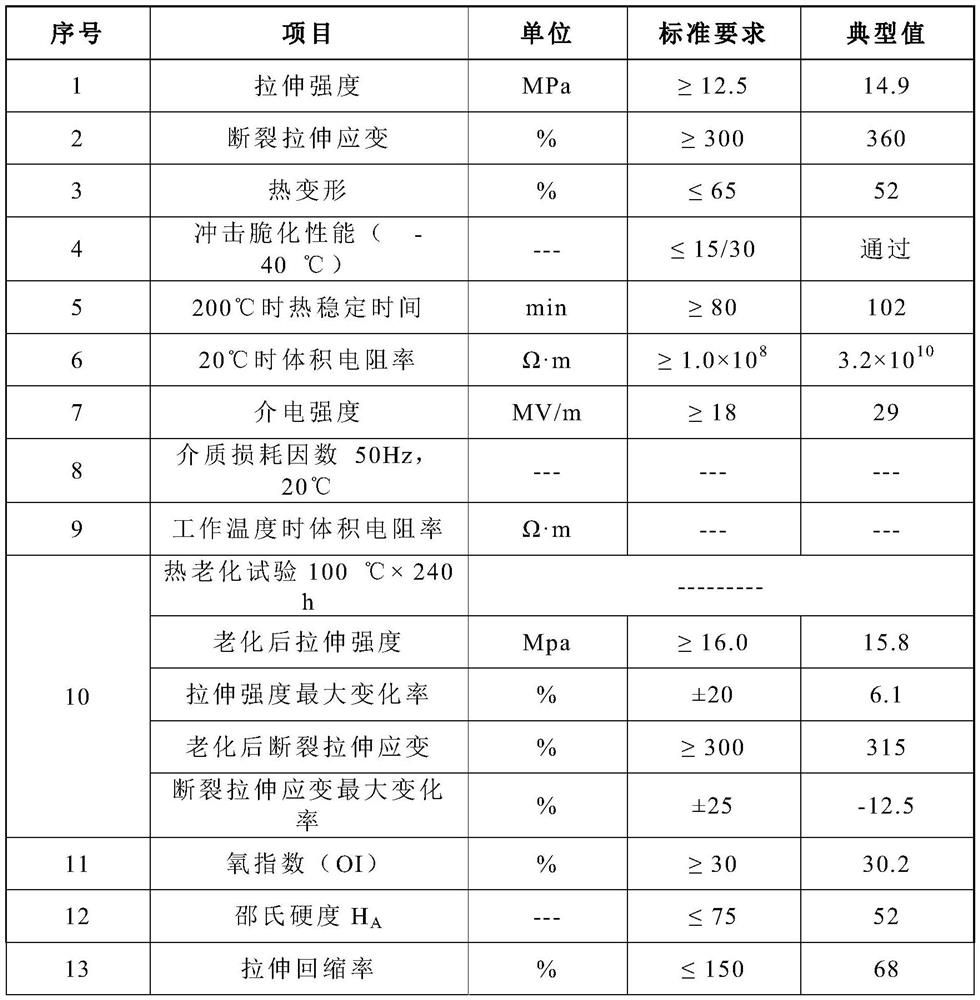

Image

Examples

Embodiment 1

[0049] This 90℃ soft polyvinyl chloride elastomer sheathing material includes the following components:

[0050] Polyvinyl chloride resin: 100 parts,

[0051] Plasticizer: 50 parts,

[0052] Filler: 20 parts,

[0053] Processing modifier: 20 parts,

[0054] Flame retardant: 15 parts,

[0055] Stabilizer: 8 parts,

[0056] Lubricant: 1.5 parts,

[0057] Antioxidant: 1 part.

[0058] The polyvinyl chloride resin is a polyvinyl chloride resin with an average degree of polymerization of 1300.

[0059] The plasticizer is one or more of trioctyl trimellitate, polyester plasticizer, dioctyl sebacate, dioctyl terephthalate, and epoxidized soybean oil.

[0060] The filler is one or more of nano calcined kaolin, nano calcium carbonate, superfine ground calcium carbonate, talcum powder and white carbon black.

[0061]The processing modifier is one or more of acrylate core-shell copolymer, chlorinated polyethylene, nitrile rubber, EPDM rubber, ethylene-butylene copolymer, ethylene...

Embodiment 2

[0078] This 90℃ soft polyvinyl chloride elastomer sheathing material includes the following components:

[0079] Polyvinyl chloride resin: 100 parts,

[0080] Plasticizer: 80 parts,

[0081] Filler: 50 parts,

[0082] Processing modifier: 50 parts,

[0083] Flame retardant: 40 parts,

[0084] Stabilizer: 16 parts,

[0085] Lubricant: 5 parts,

[0086] Antioxidant: 3 parts.

[0087] The polyvinyl chloride resin is a polyvinyl chloride resin with an average degree of polymerization of 2500.

[0088] The plasticizer is one or more of trioctyl trimellitate, polyester plasticizer, dioctyl sebacate, dioctyl terephthalate, and epoxidized soybean oil.

[0089] The filler is one or more of nano calcined kaolin, nano calcium carbonate, superfine ground calcium carbonate, talcum powder and white carbon black.

[0090] The processing modifier is one or more of acrylate core-shell copolymer, chlorinated polyethylene, nitrile rubber, EPDM rubber, ethylene-butylene copolymer, ethylen...

Embodiment 3

[0107] This 90℃ soft polyvinyl chloride elastomer sheathing material includes the following components:

[0108] Polyvinyl chloride resin: 100 parts,

[0109] Plasticizer: 60 parts,

[0110] Filler: 33 parts,

[0111] Processing modifier: 32 parts,

[0112] Flame retardant: 31 parts,

[0113] Stabilizer: 11 parts,

[0114] Lubricant: 3 parts,

[0115] Antioxidant: 2 parts.

[0116] The polyvinyl chloride resin is a polyvinyl chloride resin with an average degree of polymerization of 1900.

[0117] The plasticizer is one or more of trioctyl trimellitate, polyester plasticizer, dioctyl sebacate, dioctyl terephthalate, and epoxidized soybean oil.

[0118] The filler is one or more of nano calcined kaolin, nano calcium carbonate, superfine ground calcium carbonate, talcum powder and white carbon black.

[0119] The processing modifier is one or more of acrylate core-shell copolymer, chlorinated polyethylene, nitrile rubber, EPDM rubber, ethylene-butylene copolymer, ethylen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com