Polyester resin as well as preparation method and application thereof

A polyester resin, step-by-step polymerization technology, applied in applications, household utensils, inks, etc., can solve the problems of resin hardness, flexibility deviation, and inability to meet the requirements of flexible inks, and achieve the effect of increased elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

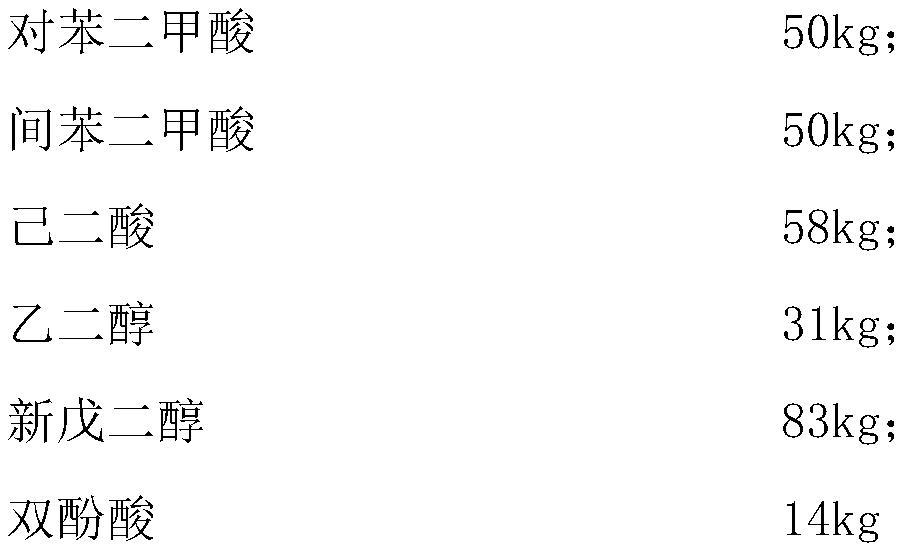

[0026] A polyester resin comprising:

[0027]

[0028] Wherein the total molar content of ethylene glycol and neopentyl glycol is 1.3 times of the total molar content of terephthalic acid, isophthalic acid and adipic acid.

[0029] The molar content of bisphenolic acid is 5% of the total molar content of terephthalic acid, isophthalic acid and adipic acid.

[0030] A polyester resin and a preparation method thereof, comprising the steps of: putting all of the above-mentioned monomers except bisphenolic acid and 72 g of isopropyl titanate into a reaction kettle, replacing the air with nitrogen to discharge the air, stirring to raise the temperature, React at 220°C. When the by-product reaches the theoretical value, add bisphenolic acid and keep the temperature at 220°C for 1.2 hours. Reduced pressure and compression polymerization, the reaction temperature is 250°C, stop the reaction after reaching the end point, fill with nitrogen to eliminate the vacuum, and extrude the m...

Embodiment 2

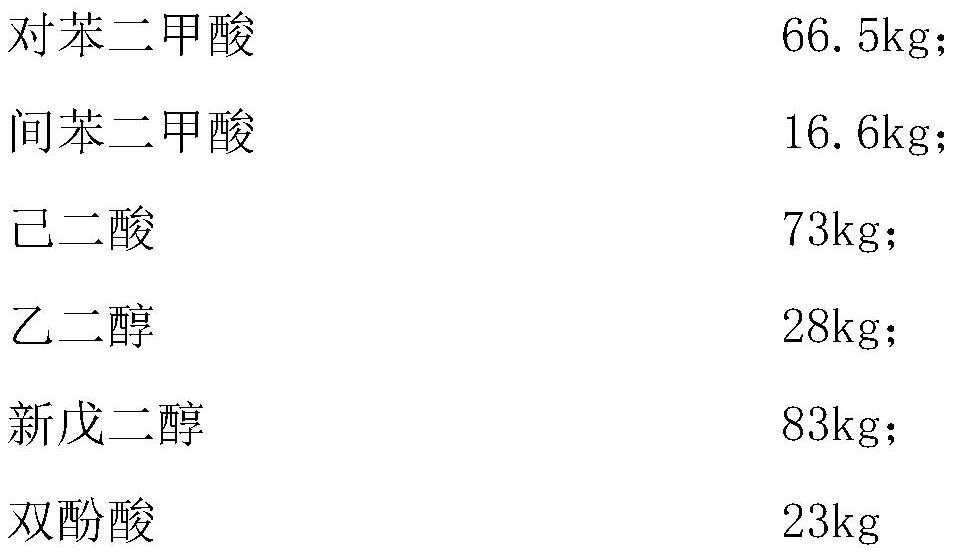

[0032] A polyester resin comprising:

[0033]

[0034] Wherein the total molar content of ethylene glycol and neopentyl glycol is 1.25 times of the total molar content of terephthalic acid, isophthalic acid and adipic acid.

[0035] The molar content of bisphenolic acid is 8% of the total molar content of terephthalic acid, isophthalic acid and adipic acid.

[0036] A polyester resin and a preparation method thereof, comprising the steps of: putting all of the above-mentioned monomers except bisphenolic acid and 72 g of tetrabutyl titanate into a reaction kettle, replacing the air with nitrogen to discharge the air, stirring to raise the temperature, React at 240°C. When the by-product reaches the theoretical value, add bisphenolic acid and keep the temperature at 240°C for 1.5h. Reduced pressure polymerization, the reaction temperature is -280°C, stop the reaction after reaching the end point, fill with nitrogen to eliminate the vacuum, and squeeze Discharge.

Embodiment 3

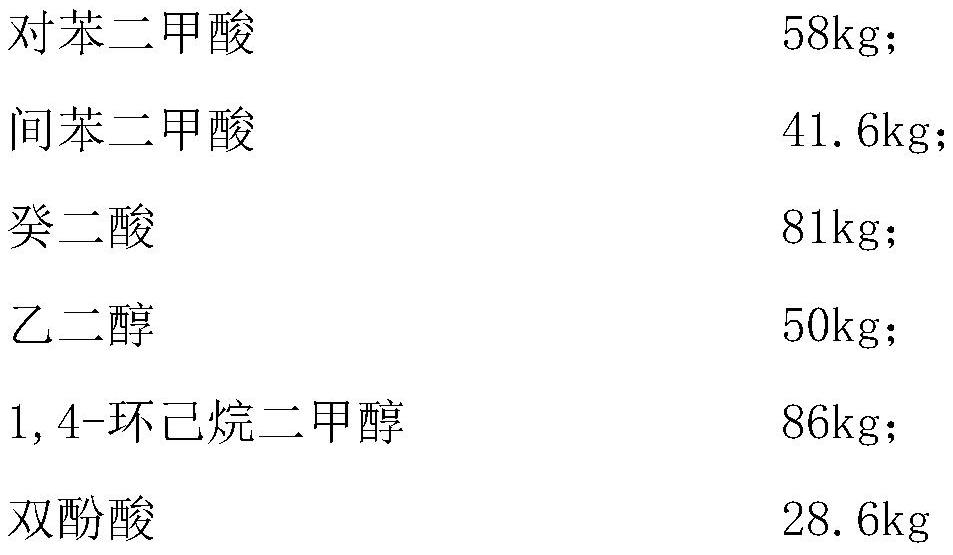

[0038] A polyester resin comprising:

[0039]

[0040] The total molar content of ethylene glycol and 1,4-cyclohexanedimethanol is 1.4 times the total molar content of terephthalic acid, isophthalic acid and sebacic acid.

[0041] The molar content of bisphenolic acid is 10% of the total molar content of terephthalic acid, phthalic acid and sebacic acid.

[0042] A polyester resin and a preparation method thereof, comprising the steps of: putting all of the above-mentioned monomers except bisphenolic acid and 72 g of tetrabutyl titanate into a reaction kettle, replacing the air with nitrogen to discharge the air, stirring to raise the temperature, React at 220°C. When the by-product reaches the theoretical value, add bisphenolic acid, keep the temperature at 220°C for 2 hours, reduce pressure and polymerize, the reaction temperature is 250°C, stop the reaction after reaching the end point, fill with nitrogen to eliminate the vacuum, and extrude the material .

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com