A kind of anchor sealing mortar and preparation method thereof

A technology of mortar and water reducer, which is applied in the field of construction engineering, and can solve the problems of corrosion of prestressed tendons of track slabs, affecting the durability of track slabs and sleepers, and affecting durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

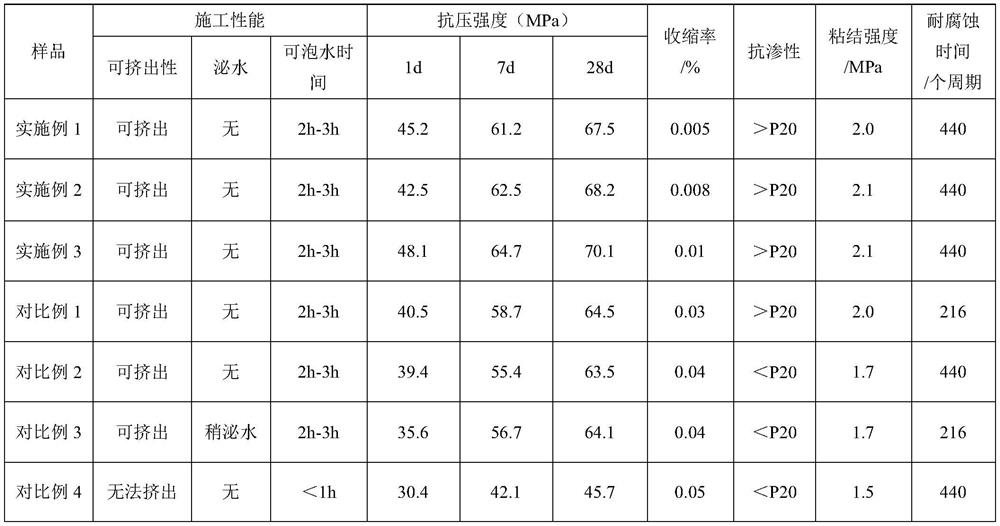

Examples

Embodiment Construction

[0026] The present invention will be described in detail below with reference to the embodiments.

[0027] The model of the one-component water-curable polyurethane waterproof coating used in the examples and comparative examples of the present invention is HC-21, and the manufacturer is Guangdong Aidis New Material Technology Co., Ltd.

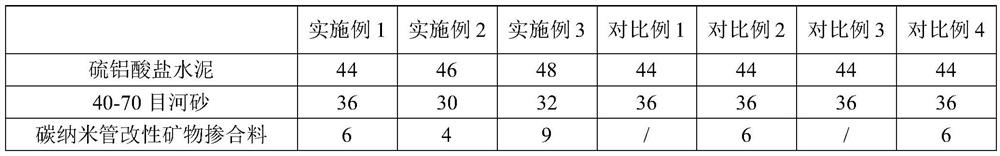

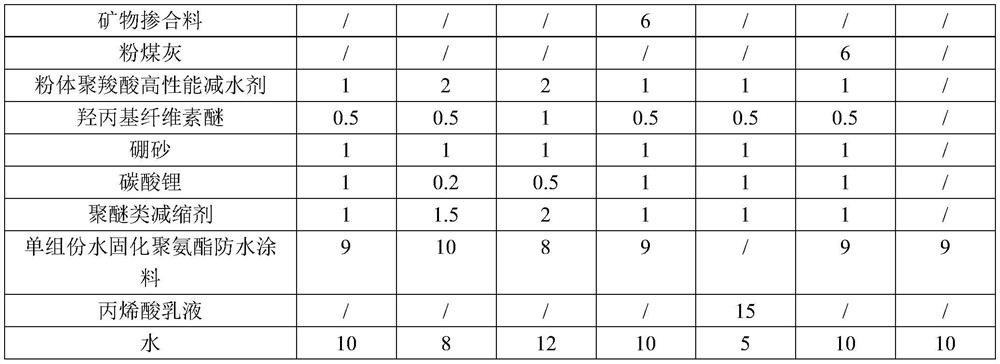

[0028] The anchor-sealing mortar in each example and the comparative example includes the raw materials in parts by weight as shown in Table 1, and the raw materials and weight percentages of the carbon nanotube-modified mineral admixture in the raw materials are shown in Table 2.

[0029] Raw materials and parts by weight of the anchor mortar in each embodiment and comparative example of Table 1

[0030]

[0031]

[0032] In the table: the mineral admixture is composed of the following raw materials by weight: 28 parts of fly ash, 4 parts of carbon nanotubes, 55 parts of ultrafine mineral powder, 8 parts of silica fume, 5 parts of Yuan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com