Treatment method and complete equipment suitable for high-liquid-content oil-containing sludge

A technology of oily sludge and sludge, applied in water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, natural water treatment, etc., can solve the problem of damage and deformation of drying equipment, and it is difficult to realize long-term stable operation of industrialization and other issues to achieve the effect of harmless

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to have a clearer understanding of the technical features, purposes and beneficial effects of the present invention, the technical solution of the present invention is described in detail below, but it should not be construed as limiting the scope of implementation of the present invention.

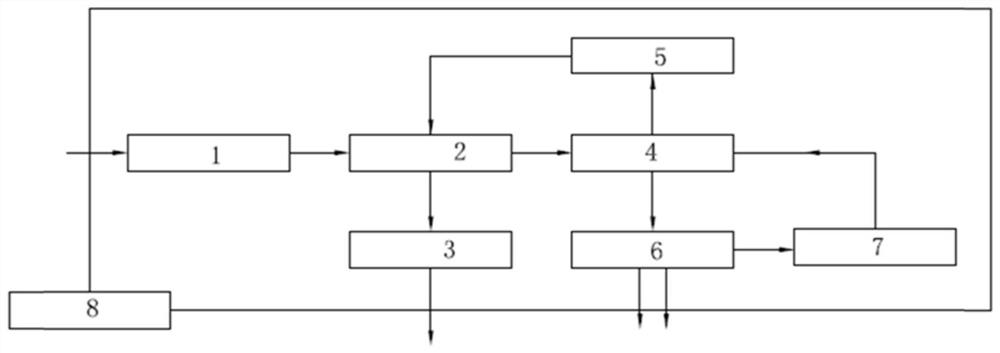

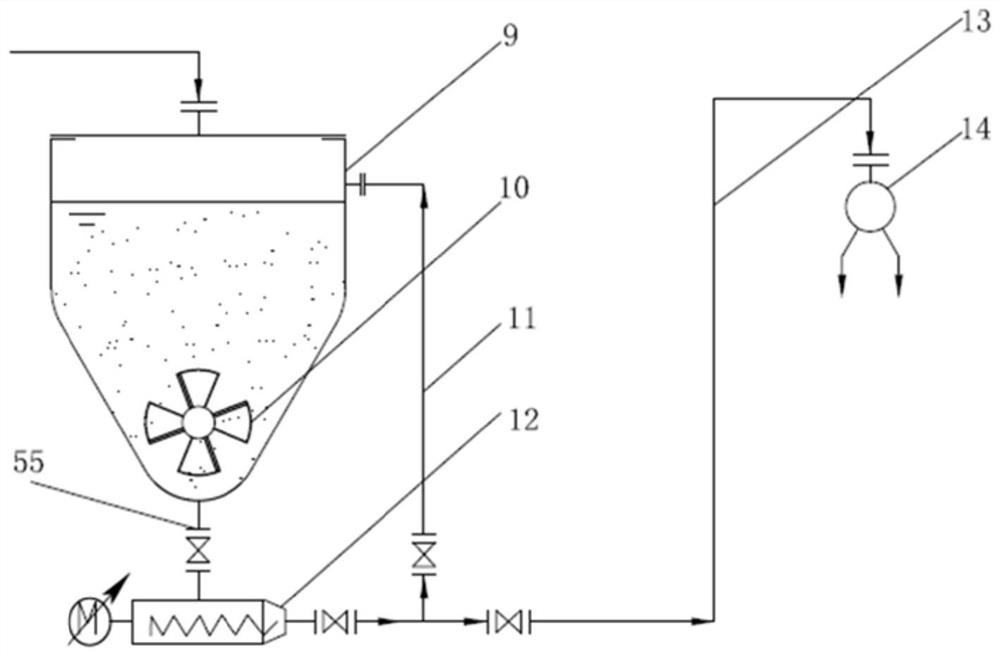

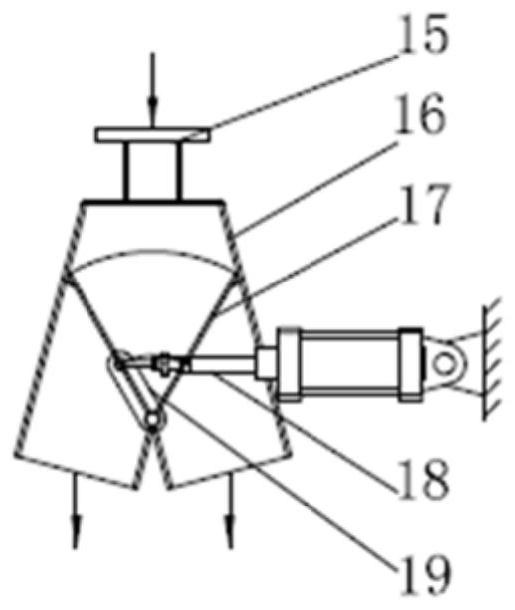

[0034] Such as figure 1As shown, the complete set of processing equipment for high liquid and oily sludge in the present invention includes an automatic control unit 8 for unified and coordinated control, a pretreatment feed unit 1 and an indirect thermal desorption unit 2, and a high-temperature slag with the indirect thermal desorption unit 2 The discharge processing unit 3 connected to the soil outlet, the condensing unit 4 connected to the desorption steam outlet of the indirect thermal desorption unit 2, the non-condensable gas processing unit 5 connected to the exhaust port of the condensing unit 4, and the drain port of the condensing unit 4 The connected circulatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com