Seamless hot pressing device for down jacket fabric

A technology for down jacket fabrics and heat-pressing devices, which is applied in the field of seamless heat-pressing devices for down jacket fabrics, can solve problems affecting the health of workers, affecting the quality of fabrics, and pollution of the working environment, so as to increase application scenarios and durability, reduce Pollution, effects of high degree of mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

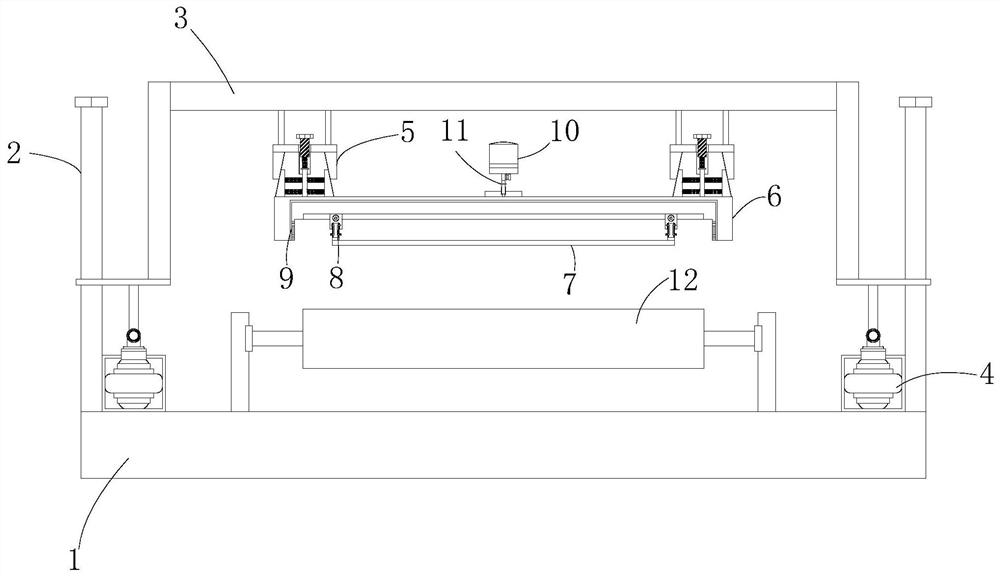

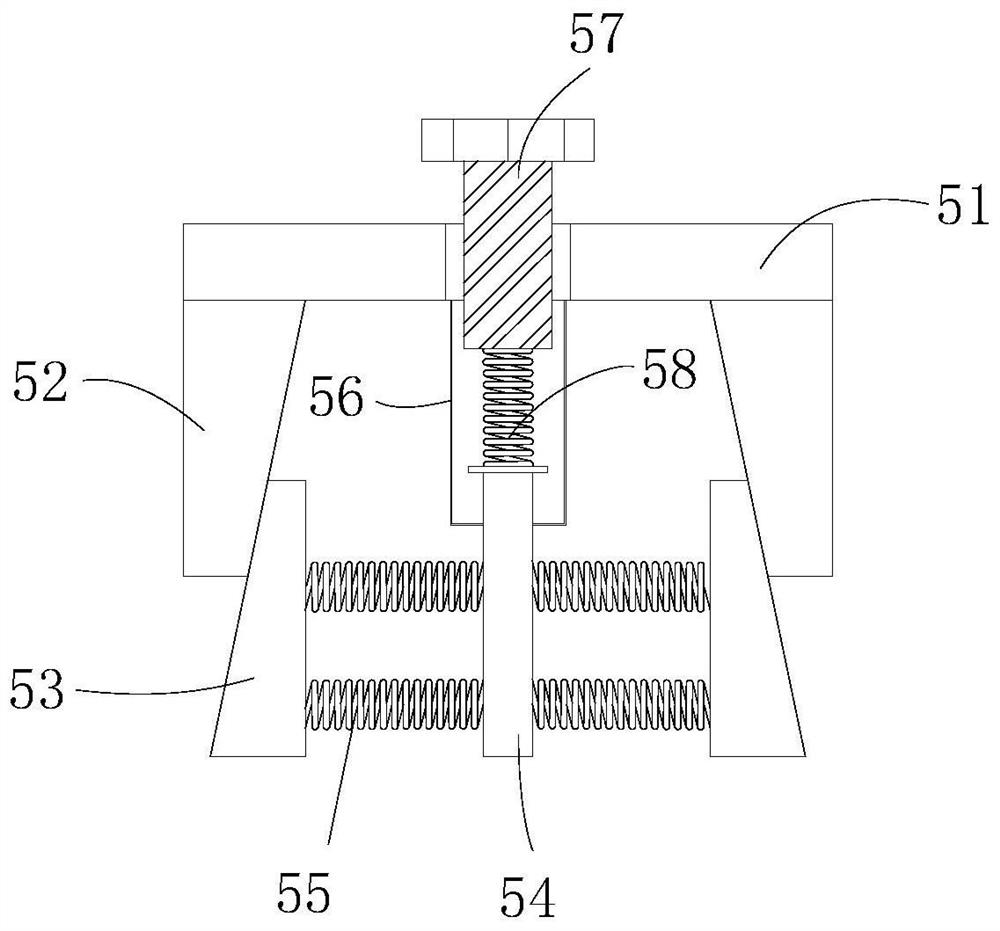

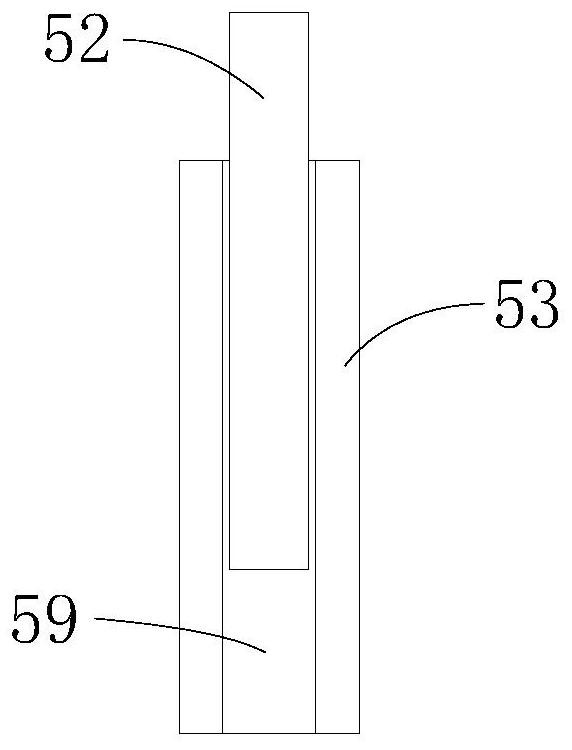

[0025] Such as Figure 1-5 As shown, a seamless hot-pressing device for down jacket fabrics includes a base 1, a guide column 2, and a hot-press lifting bracket 3 sleeved on the guide column 2. The hot-press lifting bracket 3 is driven to lift by a telescopic cylinder 4, and the base 1 The upper end surface of the upper surface is provided with a fabric placing plate 12, and the position corresponding to the fabric placing plate 12 is provided with a pressing plate 7 through the hot pressing adjustment mechanism 5 on the hot-press lifting support 3, and the fabric is placed on the fabric placing plate 12 and makes the material in the fabric The strip hole and the alignment reference line of the fabric on the fabric placement plate 12 are aligned and coincident. Under one hot pressing operation of the hot press, the fabric can be bonded and the production efficiency is improved. Compared with the existing production method Said that the degree of labor participation has decreas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com