Method for effectively relieving anode poisoning of proton exchange membrane fuel cell by differential pressure oxygen permeation

A proton exchange membrane, fuel cell technology, applied in fuel cells, circuits, electrical components, etc., can solve the problems of complex operation, reduced hydrophobicity of the catalyst layer, low recovery ratio, etc., and achieves the effect of simple and easy method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

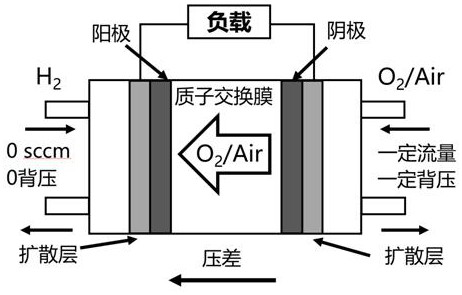

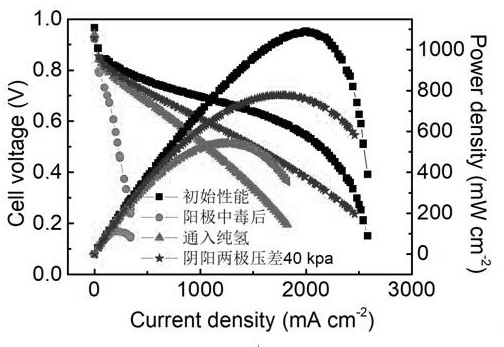

[0026] After the anode poisoning of the fuel cell occurs, the gas flow rate of the anode side is 500 sccm high-purity hydrogen, and the gas flow rate of the cathode side is 500 sccm oxidant gas. At this time, the back pressure of the cathode and anode is adjusted to 0 kpa; The flow rate was kept constant, and only the back pressure was set on the cathode, so that a pressure difference of 40 kpa was generated on both sides of the cathode and anode; the cathode gas flow rate was kept constant, and the flow rate on the anode side was set to 0, and maintained under this pressure difference condition for 1 h. Keeping the flow rate of the cathode gas constant, a certain flow rate of high-purity hydrogen gas is passed into the anode side of the fuel cell, and the back pressure drop on the cathode side is set to 0, and then the fuel cell is activated for an activation test. figure 2 For feeding 5 ppm H 2 Polarization curves and power density curves of fuel cells after S poisoning, re...

Embodiment 2

[0028] Using the same test method as in Example 1, the pressure difference between the cathode and the anode was changed to 25 kpa. The study found that, consistent with the results of Example 1, compared with the performance recovery ratio of the pure hydrogen battery, the battery performance recovery under the pressure difference 25 kpa mitigation strategy also increased significantly, reaching 84.7%. The amount decreased, and the recovery rate also decreased.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com