High-strength steel differential stable austenitic friction stir welding method and welding joint

A friction stir and welding method technology, applied in the field of metal plastic processing, can solve the problems of large welding torque and forward resistance, large plastic deformation and heat input, difficult to meet application requirements, etc., so as to reduce the time cost and reduce the heat affected zone. , The effect of improving the utilization rate of welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

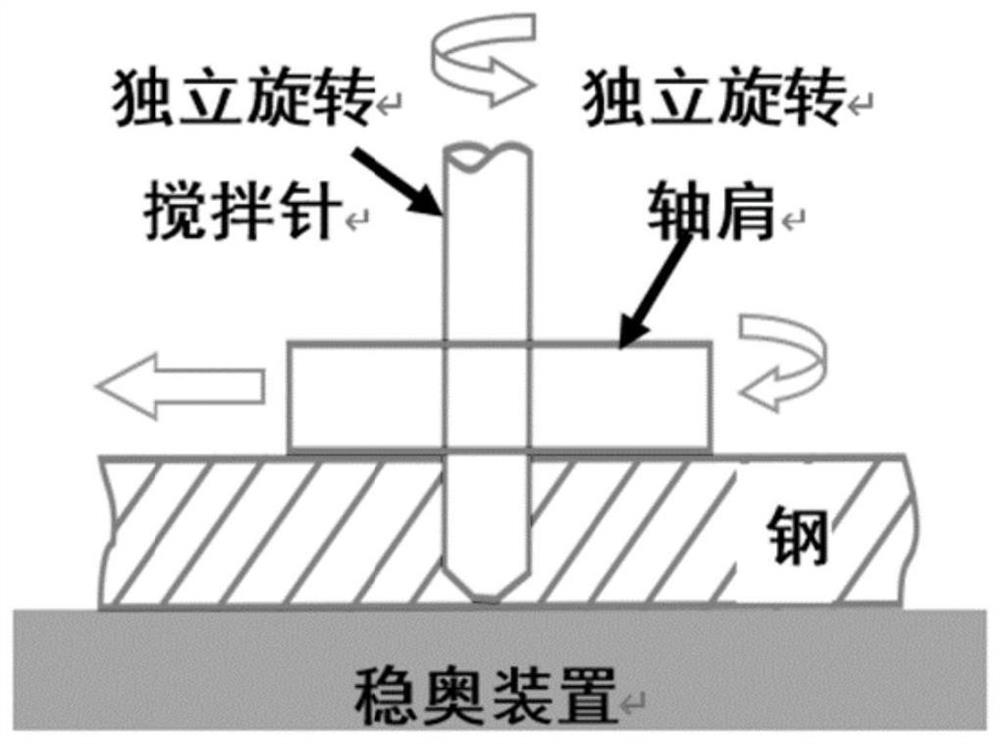

[0068] This embodiment provides a high-strength steel differential stable Austrian friction stir welding method, including heating the high-strength steel for the first heat preservation, and then using the shoulder and stirring to perform rotary friction stir welding on the high-strength steel, Then cool to holding temperature, carry out second holding temperature, then cool to room temperature;

[0069] The shaft shoulder and the stirring pin rotate independently, and the rotational friction stir welding includes the same direction or reverse differential rotational friction stir welding.

[0070] Specifically include:

[0071] Step 1: heat the high-strength steel for the first heat preservation, the temperature of the first heat preservation is 50°C-600°C, and the heat preservation time is 15-30s; the purpose is to preheat the welding plate, so that the welding process Reduced pressing force while improving weld formability.

[0072] Step 2: Rotating friction stir welding...

Embodiment 2

[0085] The difference between this embodiment and Embodiment 1 is that this embodiment welds QP980 steel with a thickness of 1.8mm, the length of the stirring needle is 1.5mm, the rotation speed is 400rpm, the rotation speed of the shoulder is 400rpm, and the reduction is 0.2mm. The forward speed is 200mm / min.

[0086] The first holding temperature is 400°C, and the holding time is 15s. The second holding temperature is 350°C, and the holding time is 10 minutes. According to the carbon constraint quasi-equilibrium theory, the holding temperatures are 400°C and 350°C. The first heat preservation is equivalent to the preheating effect before FSW welding. The second heat preservation is to achieve element distribution, in order to avoid the formation of martensite, let C partition into austenite.

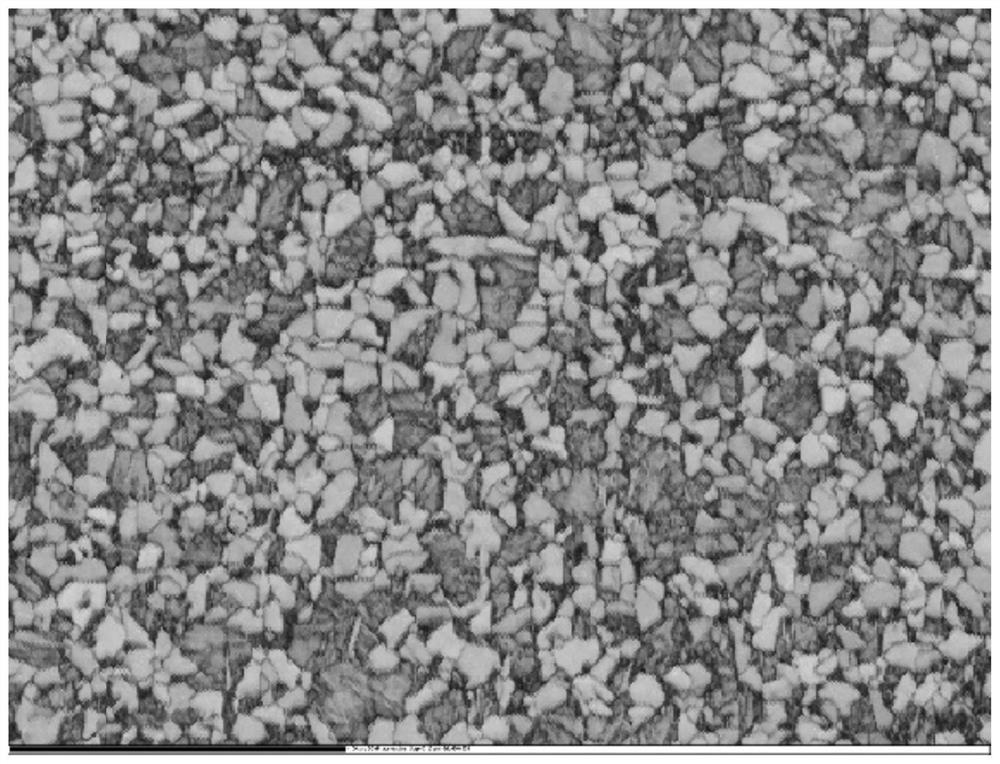

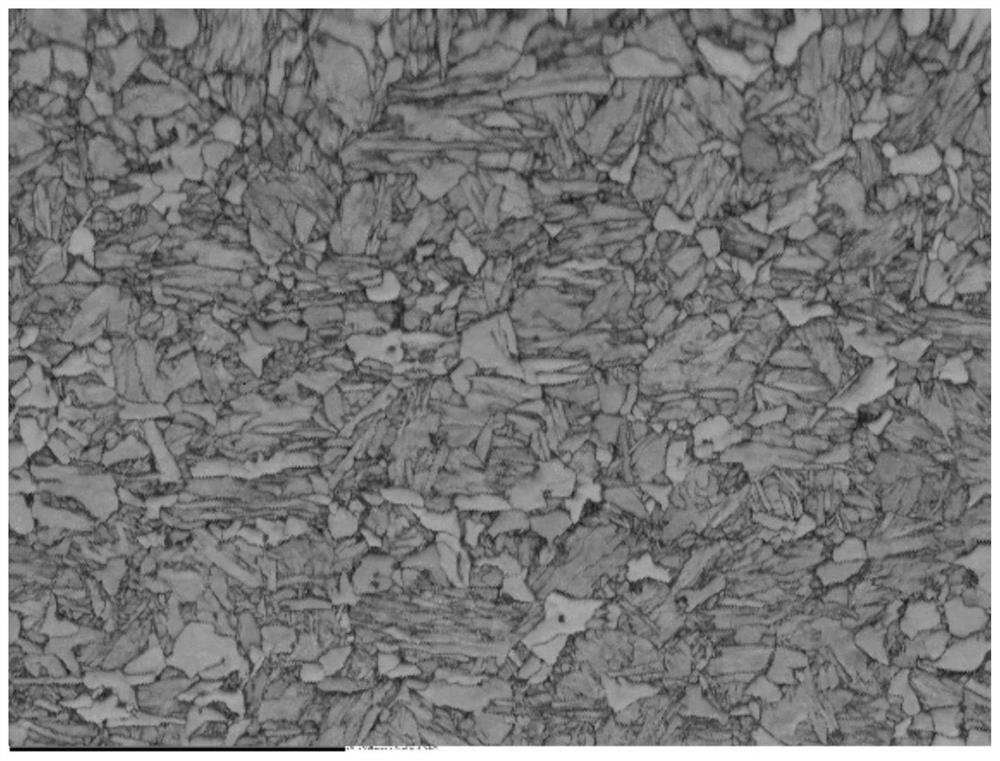

[0087] After testing, the residual austenite content of the obtained welded joint is about 2.7% ( Figure 5 , 6 ).

Embodiment 3

[0093] This embodiment is the same as Embodiment 2, except that the material is QP1180 steel, the stirring needle is 1.6 mm long, the rotation speed is 400 rpm, the shaft shoulder rotation speed is 350 rpm, the reduction is 0.2 mm, and the forward speed is 150 mm / min.

[0094]The first holding temperature is 450°C, holding time is 25s, the second holding temperature is 500°C, holding time is 10min, the residual austenite content of the obtained welded joint is about 1.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com