Manufacturing method of bulk amorphous alloy and bulk amorphous alloy

A technology of amorphous alloy and manufacturing method, which is applied to the manufacturing field of bulk amorphous alloy and bulk amorphous alloy, can solve the problems of weakening the strength of amorphous alloy, and achieves the improvement of cooling speed, improving the quality of amorphous connection, reducing the The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

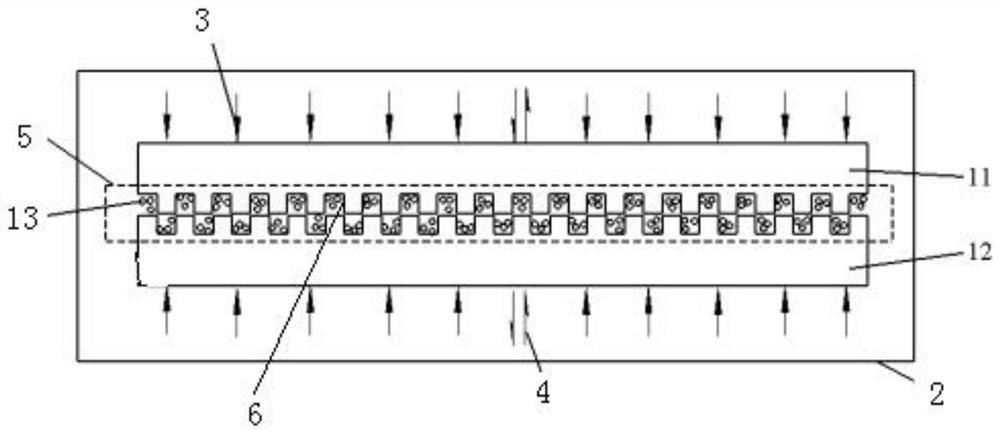

[0034] In a method for manufacturing a bulk amorphous alloy disclosed in this embodiment, the components of the first amorphous alloy 11 and the first amorphous alloy 12 are both Zr 41.2 Ti 13.8 Cu 12.5 Ni 10 be 22.5 , Tg is 623K, Tx is 700K, and the microstructure 6 that is relatively engaged is processed at the interface between the first amorphous alloy 11 and the first amorphous alloy 12 to be connected, and is installed in the working chamber 2, and the vacuum in the working chamber 2 is maintained .

[0035] Such as figure 1 As shown, the relative position is adjusted, and the powder medium is filled in the middle of the connection interface. The amorphous alloy powder 13 is selected. The material of the amorphous alloy powder 13 is the same as that of the first amorphous alloy 11 and the first amorphous alloy 12. The material of the amorphous alloy powder 13 is 70 μm in particle size, and a pressure 3 is applied to the first amorphous alloy 11 and the first amorpho...

Embodiment 2

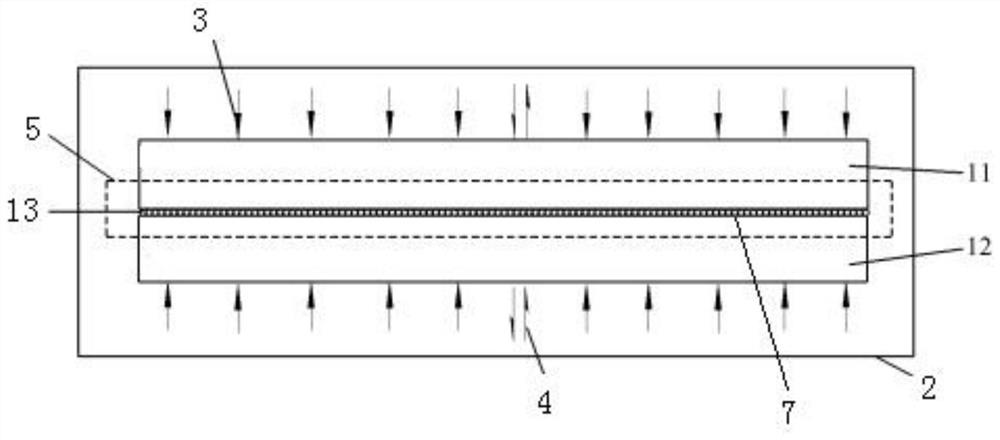

[0038] In the manufacturing method of a bulk amorphous alloy disclosed in this embodiment, the first amorphous alloy 11 is composed of Zr 44 Ti 11 Cu 10 Ni 10 be 25 , Tg is 624K, Tx is 745K, the composition of the first amorphous alloy 12 is Zr 58.5 Nb2.8 Cu 15.6 Ni 12.8 Al 10.3 , Tg is 674K, and Tx is 754K. The interface to be connected between the first amorphous alloy 11 and the first amorphous alloy 12 is polished to obtain a polished surface 7, which is installed in the working chamber 2, and the working chamber 2 is filled with nitrogen gas.

[0039] Such as figure 2 As shown, adjust its relative position, and fill the amorphous alloy powder 13 in the middle of the connection interface. The material of the amorphous alloy powder 13 is Zr 58.5 Nb 2.8 Cu 15.6 Ni 12.8 Al 10.3 , the diameter of the amorphous alloy powder 13 is 30 μm, and a pressure 3 is applied to the first amorphous alloy 11 and the first amorphous alloy 12. The connecting interface is heated...

Embodiment 3

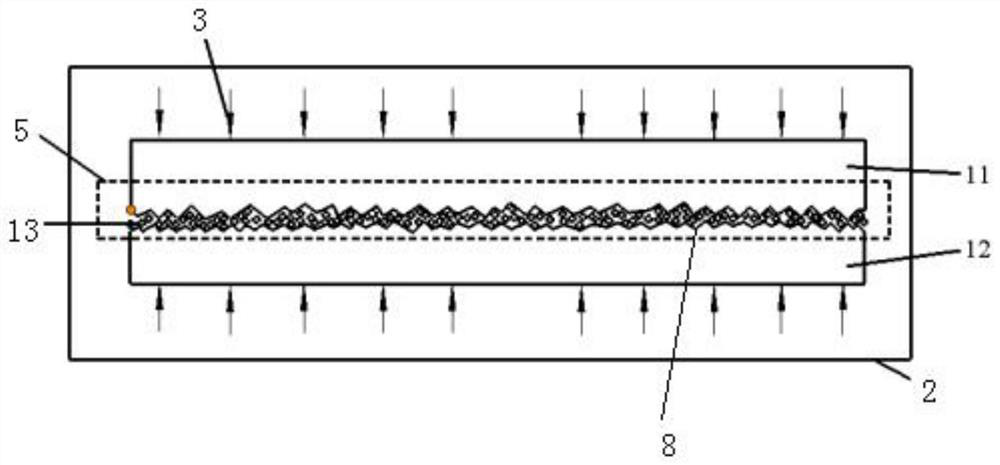

[0042] In the manufacturing method of a bulk amorphous alloy disclosed in this embodiment, the first amorphous alloy 11 is composed of Zr 41.2 Ti 13.8 Cu 12.5 Ni 10 be 22.5 , Tg is 639K, Tx is 693K, the composition of the first amorphous alloy 12 is Pd 47 Ni 10 Cu 30 P 13 , Tg is 628K, and Tx is 674K. Use 200# sandpaper to roughen the interface between the first amorphous alloy 11 and the first amorphous alloy 12 to obtain a rough surface 8, install it in the working chamber 2, and fill the working chamber 2 with nitrogen.

[0043] Such as image 3 As shown, adjust its relative position, and fill the amorphous alloy powder 13 at the connection interface, the material of the amorphous alloy powder 13 is Zr 41.2 Ti 13.8 Cu 12.5 Ni 10 be 22.5 , the powder diameter is 60 μm, and a pressure 3 is applied to the first amorphous alloy 11 and the first amorphous alloy 12, and the pressure 3 is 85 MPa, and the connection interface between the first amorphous alloy 11 and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com