Comprehensive test platform for dynamic sealing performance of gas storage cover rock

A comprehensive testing and dynamic sealing technology, which is applied in the directions of using liquid/vacuum to measure liquid tightness, applying repeated force/pulsation force to test material strength, and applying stable tension/pressure to test material strength, etc., can solve the lack of and other problems, to achieve the effect of reducing the occupied space and making the test convenient and quick

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

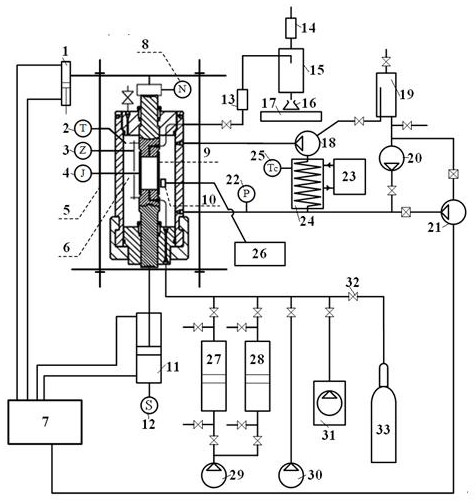

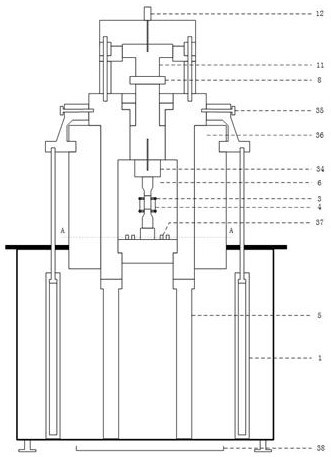

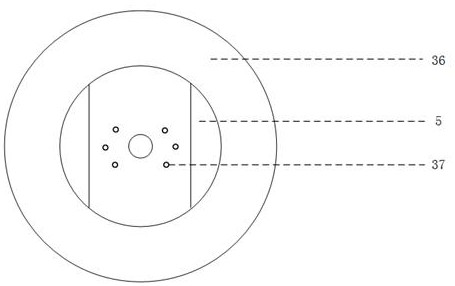

[0022] refer to figure 1 and figure 2 , a comprehensive testing platform for the dynamic tightness of rocks in the caprock of a gas storage, the comprehensive testing platform consists of a three-axis alternating mechanical control system, a temperature loading system, a gas pressurization system, a core saturation loading system, a seepage outlet monitoring system, The acoustic detection system and data acquisition and display system are connected through high-pressure connecting pipelines, valves and circuit systems.

[0023] The three-axis alternating mechanical control system consists of a three-axis rigid reaction frame 5, a self-balancing pressure chamber 6, a pressure chamber opening and closing cylinder 1, a pressure chamber annular hatch 36, an axial enclosure control system 7, and an axial pressure loading cylinder 11. Displacement sensor 12, axial load force sensor 8, confining pressure fluid storage tank 19, liquid filling pump 20, confining pressure loading pump...

Embodiment 2

[0037] Such as figure 1 As shown, the test method of the comprehensive test platform for the dynamic tightness of the gas storage cap rock is:

[0038] (1) Wrap the sample with an oil-proof heat-shrinkable tube 9, load the axial strain sensor 3, the radial strain sensor 4 and the acoustic emission probe 10, put it into the self-balancing pressure chamber 6 and insert the data leads into the multi-channel data The collection interface 37; through the axial surrounding control system 7, the axial loading cylinder 11 and the axial force sensor 8, a small axial load is applied to the sample to fix the sample;

[0039] (2) Close the annular hatch 36 of the pressure chamber through the opening and closing oil cylinder 1 of the pressure chamber, and insert the safety pin 35 of the pressure chamber, and pass the axial enclosure control system 7, the confining pressure fluid storage tank 19, the liquid filling pump 20, the enclosure Pressure loading pump 21 and pressure sensor 22 carr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com