Sand making shaper and sand making method

A shaping machine and gravel technology, applied in chemical instruments and methods, solid separation, separating solids from solids with airflow, etc., can solve problems such as processing interference, insufficient impact crushing of crushed stones, and reduced crushing effect. To achieve the effect of increasing collision breaking and shaping, the shaping method is efficient, fast, and adaptable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

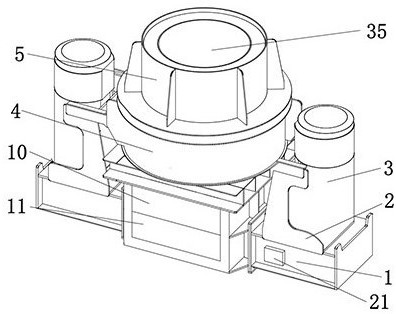

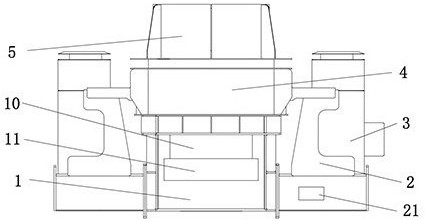

[0038] Such as Figure 1-4 , a sand shaping machine, including a base 1, the top of the base 1 is provided with multiple sets of brackets 2, the brackets 2 are used to improve the stability of the device, one side of the base 1 is provided with a controller 21, and the controller 21 is electrically controlled For each electrical component, the top of the base 1 communicates with a crushing box 4 , and the top of the crushing box 4 communicates with a feed box 5 .

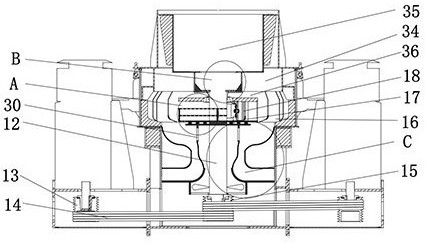

[0039] Both sides of base 1 are provided with driving device, and the output end of driving device is provided with main shaft 12, and driving device comprises two groups of driving motors 3, and driving motor 3 is fixedly connected with the both sides tops of base 1, and the output shaft of driving motor 3 is provided with Driving wheel 13, the outer surface of driving wheel 13 is provided with transmission belt 14, and the other end of transmission belt 14 is connected with driven wheel 15 in rotation, and the cen...

no. 2 example

[0045] Such as Figure 5-7 , based on the sand making and shaping machine provided in the first embodiment, in actual use, the sand and gravel at the discharge port 19 are directly thrown out without screening, so the sand and gravel to be shaped will be thrown out concentratedly and Impact and collide with the surrounding guard plate 16 or the sand and gravel in the shaping cavity 36, which will cause part of the sand and gravel to be discharged and recovered along the bottom of the shaping cavity 36 under the action of its own gravity before being fully and effectively shaped and broken, thereby reducing the sand and gravel. No matter whether it is the gravel entering along the feeding hopper 35 or the gravel discharged along the shaping chamber 36 after shaping, the sediment and other impurities attached to the surface cannot be effectively cleaned, which will reduce the overall quality of the gravel. In order to solve this problem, the sand making and shaping machine also ...

no. 3 example

[0059] Such as Figure 8 , based on a sand making and shaping machine provided in the second embodiment, it is necessary to combine its internal structure and movement process to realize the overall sand making method of the sand making and shaping machine during use, including the following steps:

[0060] S1. Pour the sand to be shaped along the feed hopper 35;

[0061] S2. The controller 21 controls the opening size of the regulator 32, part of the gravel reaches the top of the third sieve plate 27 along the throwing feed inlet 31, and part of the sand and gravel squeezes out the side baffle 33 and enters the inside of the shaping cavity 36 along the shaping feed inlet 34 ;

[0062] S3. The driving device drives the main shaft 12 to rotate, and the main shaft 12 drives the material distribution tray 17 and the exhaust fan 9 to rotate;

[0063] S4. The gravel part on the top of the third sieve plate 27 falls to the top of the second sieve plate 25 along the third sieve hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com