Tapioca pearls and production process thereof

A technology of powder circle and tapioca starch, which is used in food ingredients as a taste improver, food forming, food science and other directions, can solve the problems of no taste, the inside of the powder circle is hard, the taste becomes Q-elastic, etc., and the taste is improved. , The effect of simple process operation and stable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

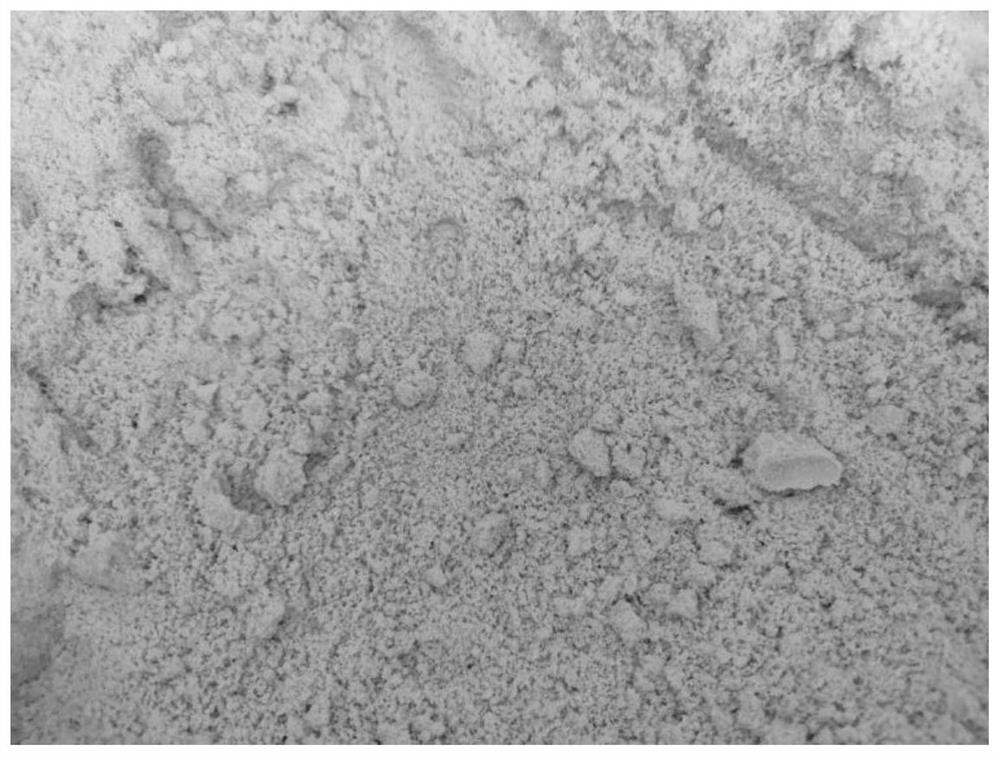

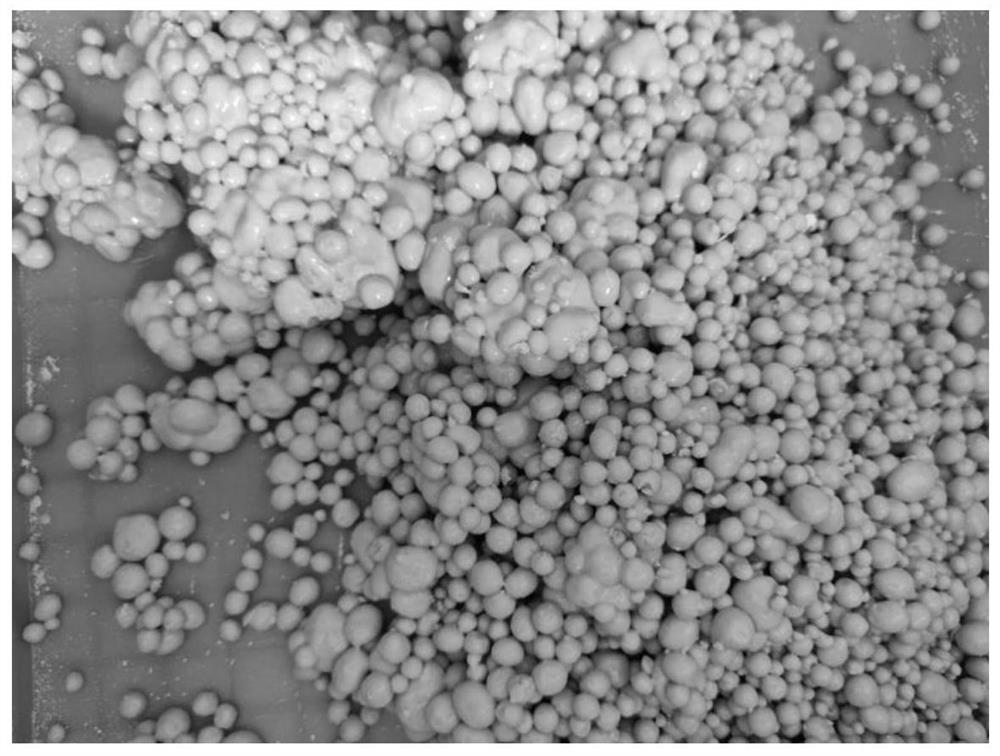

[0024] Powder preparation: Mix the following components evenly by mass fraction: 0.06% guar gum, 0.12% xanthan gum, 15.62% hydroxypropyl distarch phosphate, and 46.85% edible tapioca starch.

[0025] Preparation of water material: Mix the following components uniformly by mass fraction: 0.11% sodium dehydroacetate, 0.17% caramel color (produced by adding ammonia), 30.70% water, and 0.12% food flavor.

[0026] Powder and ball rolling: Mix the powder and water evenly, add 6.25% of first-grade white granulated sugar, mix evenly, crush until the proportion of powder under a 20-mesh sieve is ≥75%, and form into balls to obtain a powder circle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com