Compressor

A compressor and compression mechanism technology, applied in the field of compressors, can solve problems such as poor lubrication and reduction of sliding parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

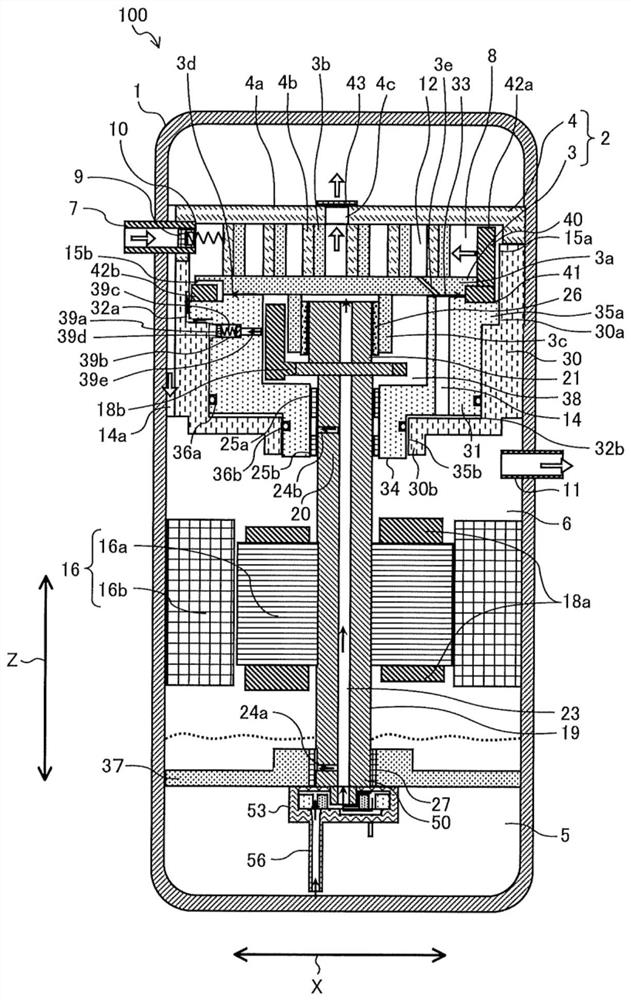

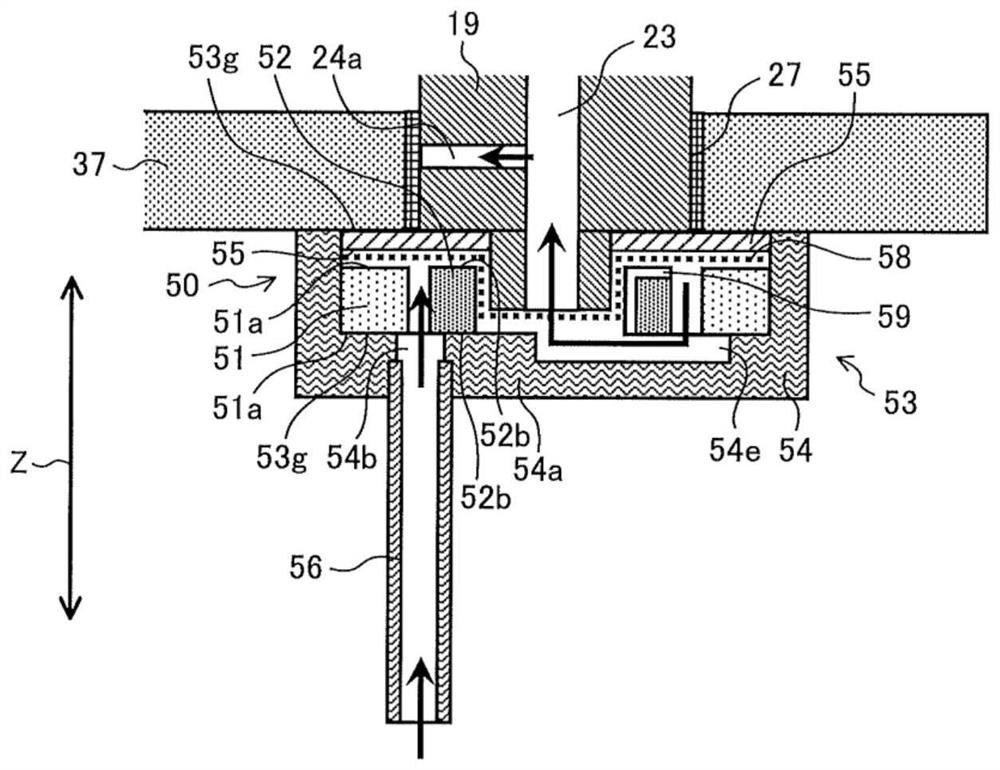

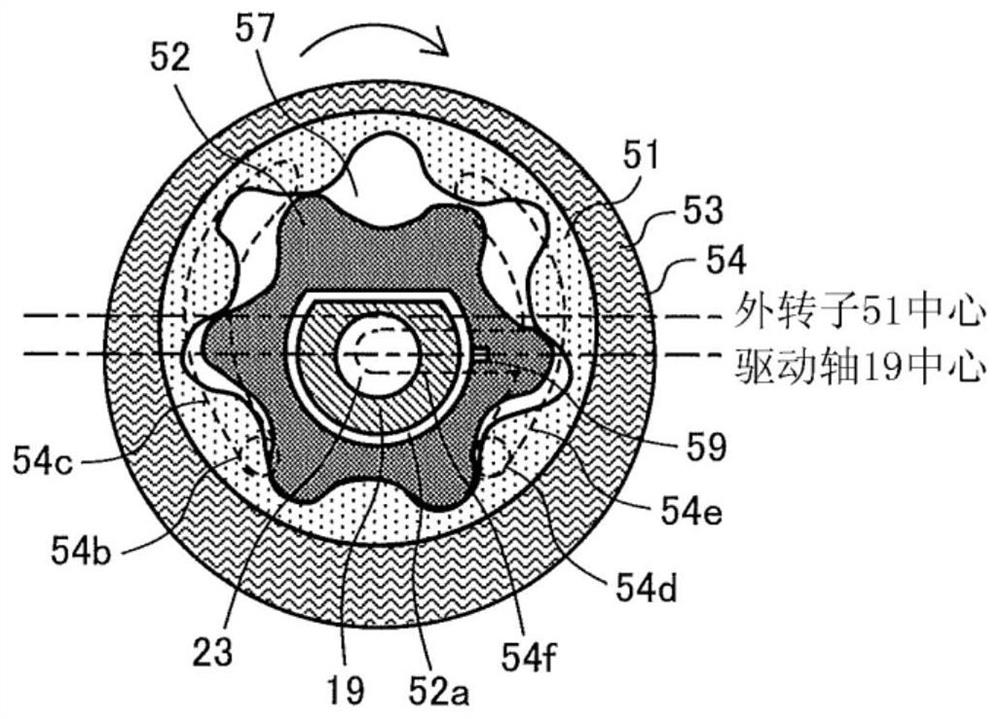

[0018] figure 1 It is a schematic longitudinal sectional view showing the compressor according to the first embodiment. As follows, while referring to figure 1 , one Next, the configuration of the compressor 100 will be described. figure 1 The compressor 100 is a so-called vertical scroll compressor, and compresses and discharges a working gas such as refrigerant, for example. The compressor 100 includes an airtight container 1 , a compression mechanism 2 , a motor 16 , and a drive shaft 19 . exist figure 2 The solid arrows in the middle airtight container 1 represent the flow of oil, and the hollow arrows represent the flow of working gas.

[0019] The airtight container 1 is formed in a cylindrical shape, for example, and has pressure resistance. A suction pipe 7 for introducing working gas into the airtight container 1 is connected to one side of the airtight container 1 , and a discharge pipe 11 for releasing compressed working gas from the airtight container 1 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com