Method for manufacturing optical assembly with microchip array and assembly

A technology of optical components and microchips, applied in optics, nonlinear optics, electrical components, etc., to improve market competitiveness, reduce chip size, and avoid optical interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments. These examples should be understood as only for illustrating the present invention but not for limiting the protection scope of the present invention. After reading the contents of the present invention, those skilled in the art can make various changes or modifications to the present invention, and these equivalent changes and modifications also fall within the scope defined by the claims of the present invention.

[0036] first preferred embodiment

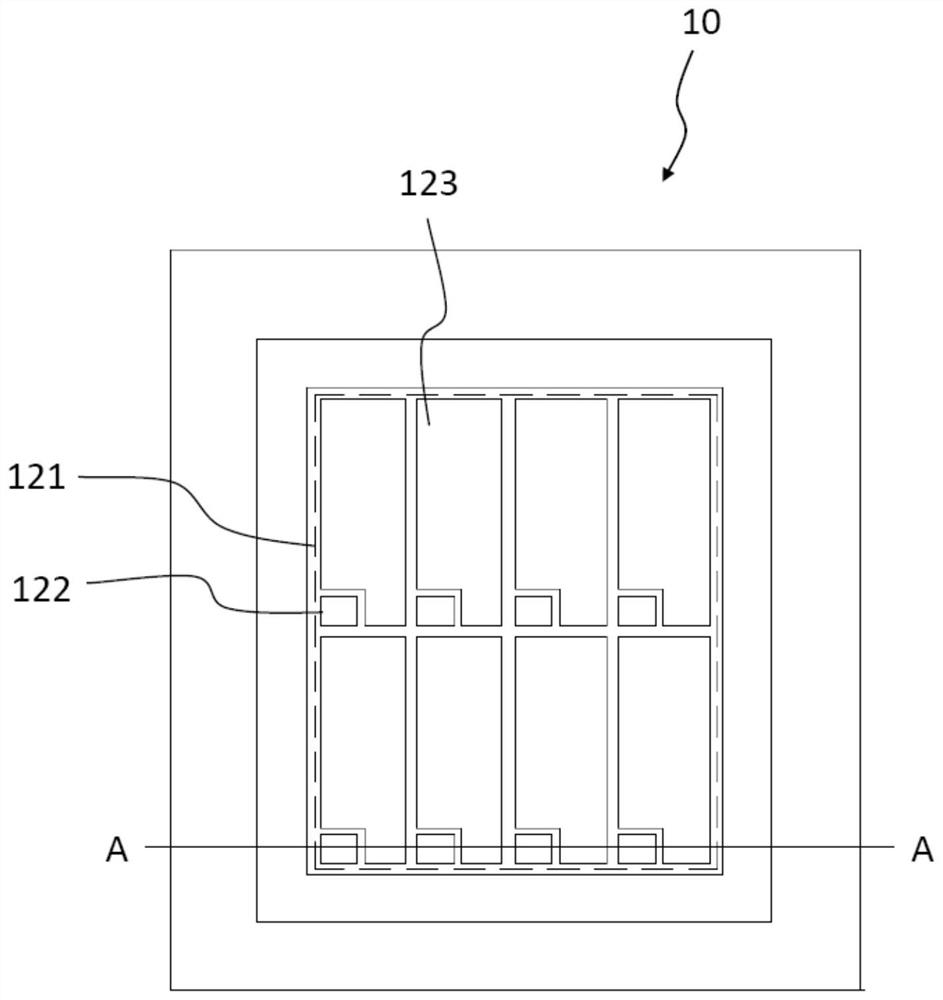

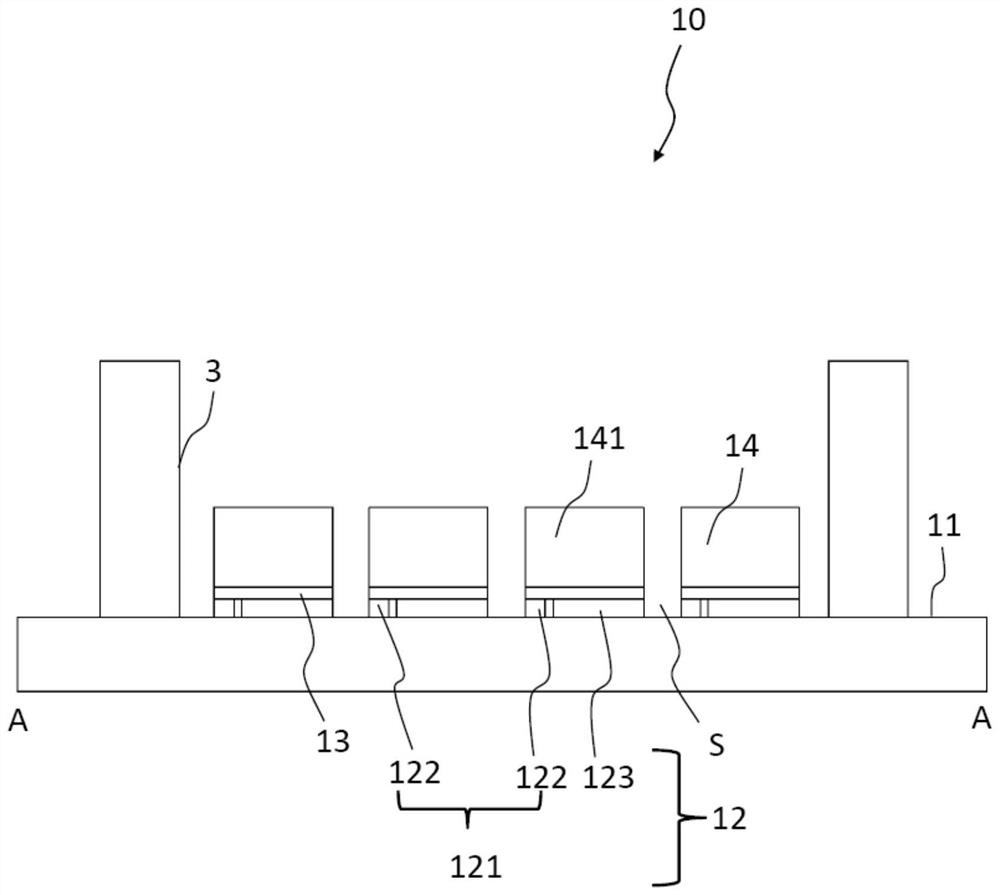

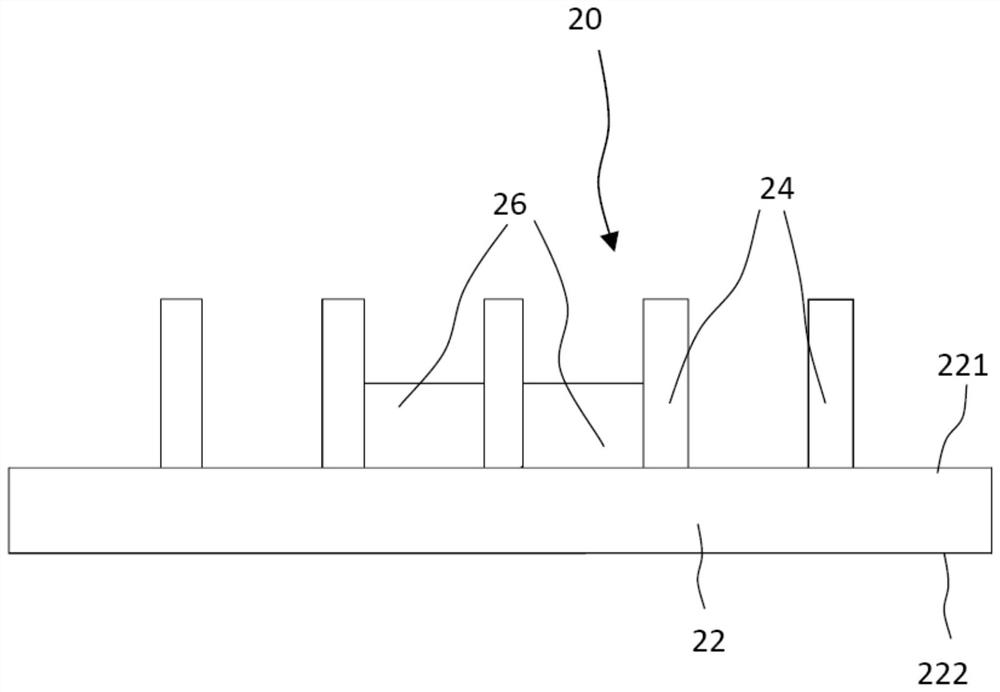

[0037] An optical component with a microchip array provided by the first preferred embodiment of the present invention is an example of a backlight module for a liquid crystal display, please refer to Figure 1-Figure 4 and Figure 6 As shown, among them, figure 1 is a top view of the array substrate 10 in the first preferred embodiment of the present invention, and figure 2 yes figure 1 I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com