Flexible pressure sensor and preparation method thereof, and wearable equipment

A pressure sensor and flexible technology, applied in the field of sensors, can solve the problems of increasing the sensor preparation process and manufacturing cost, limiting the detection range of the sensor, and delaying the response time of the sensor, achieving easy control of the detection range, ensuring stability and repeatability, The effect of eliminating the packaging process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0061] In one aspect of the invention, there is also provided a method of preparing the flexible pressure sensor described above, comprising the steps of:

[0062] The graphene composite slurry is formed on the first flexible substrate to form a preset structure, dry, prepared fork finger electrode layer;

[0063] The sensing material containing graphene is applied to the second flexible substrate and dried to prepare a compactive layer;

[0064] The onk finger electrode layer and the edge of the pressure sensitive layer are adhered by the adhesive layer having a gap.

[0065] In some embodiments, the specific steps of the preparing fork finger electrode layer include printing or printing the graphene composite slurry or printed on the first flexible substrate to form a preset structure to form a preset structure, drying. The printing can be printed directly, the printing can be a screen printing.

[0066] In some embodiments, the coating method can be screen printing, scraper coa...

Embodiment 1

[0076] 1) Preparation of the fork finger electrode layer

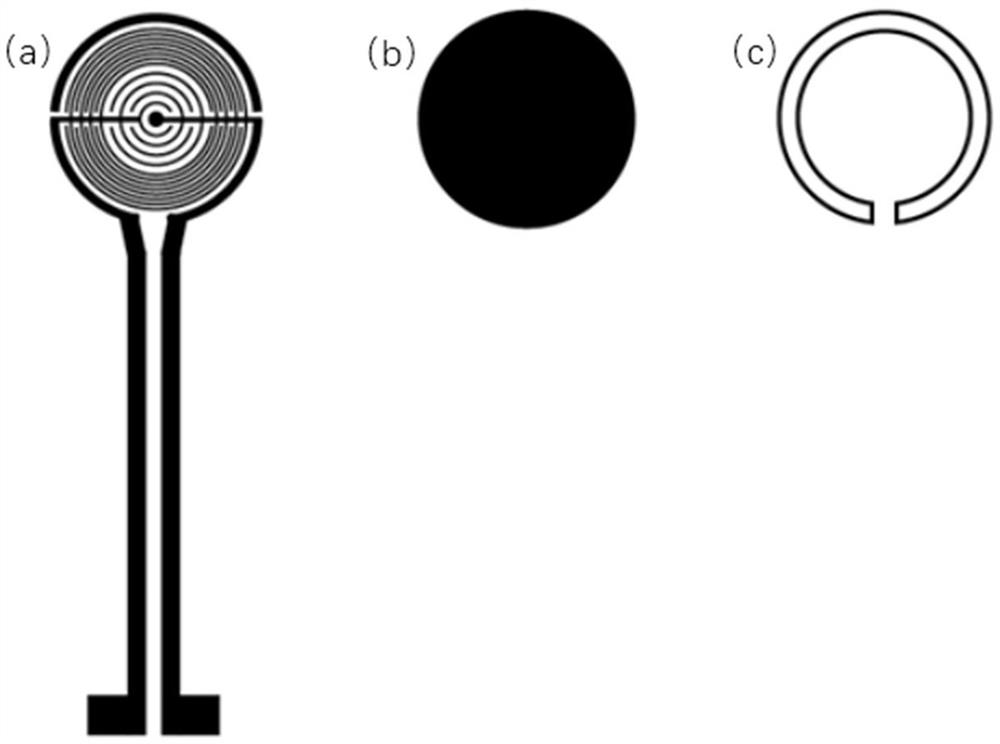

[0077] 20g of 20 g of a chlocetic resin was placed in a 80 g of a nutrioticate solvent, and the mixture was heated at 60 ° C to completely dissolve the chlorine resin, forming a chlorine resin solution. Then 20 g of a chlocene resin solution was taken, 0.8 g of graphene is added, and the dispersion is uniformly dispersed. The graphene composite slurry is printed onto the PET film using the silk screen version. figure 1 The fork finger electrode of the preset structure shown in (a), wherein the fork finger width of the fork finger electrode is 0.25 mm, and the distance between the electrode diameter is 8.5 mm, and the distance between the adjacent finger electrodes is 0.75 mm, a total of 2 pairs; At the electrode diameter of 8.5 mm to 13.75 mm, the distance between adjacent finger electrodes is 0.375 mm, and a total of 4 pairs. The PET film containing the fork refers to the electrode structure is then heated in an oven of 9...

Embodiment 2

[0087] The present embodiment is substantially the same as the preparation method of Example 1, and the difference is that the fork refers to the electrode parameters. Specific steps are as follows:

[0088] 1) Preparation of the fork finger electrode layer

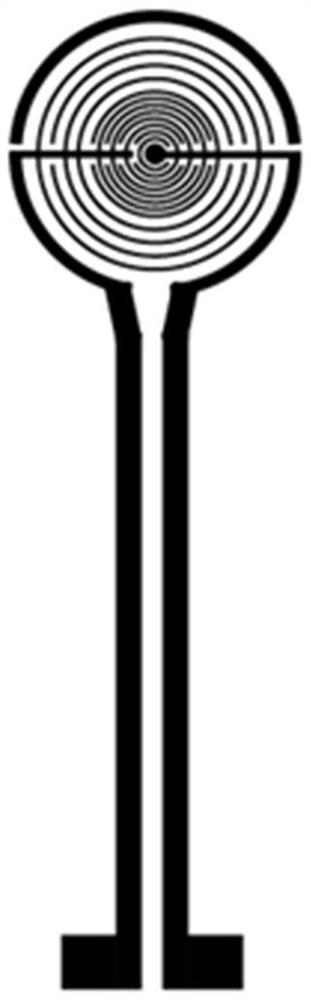

[0089]The vinegar chloride resin was placed 20g 80g dibasic ester solvent, it was heated at 60 deg.] C and stirred until the resin was completely dissolved chlorine vinegar, vinegar chloride resin solution is formed. Then take 20g vinegar chloride resin solution, was added 0.8g graphene dispersion vacuum degassing Stir 10min, to obtain graphene composite slurry. The use of silk screen printed onto the graphene composite slurry on a PET film, is formed as image 3 Fork structure shown preset finger electrodes, wherein the interdigital electrode of an interdigital width of 0.25mm, 8.5mm in inner diameter of the electrode, the distance between the adjacent interdigital electrodes 0.375 mm, a total of four pairs; electrode diamete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com