Bridge construction method and bridge dragging traction system

A bridge construction and traction system technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as bridges being difficult to drag, achieve the effect of reducing weight, reducing the impact of navigation, and realizing sharing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

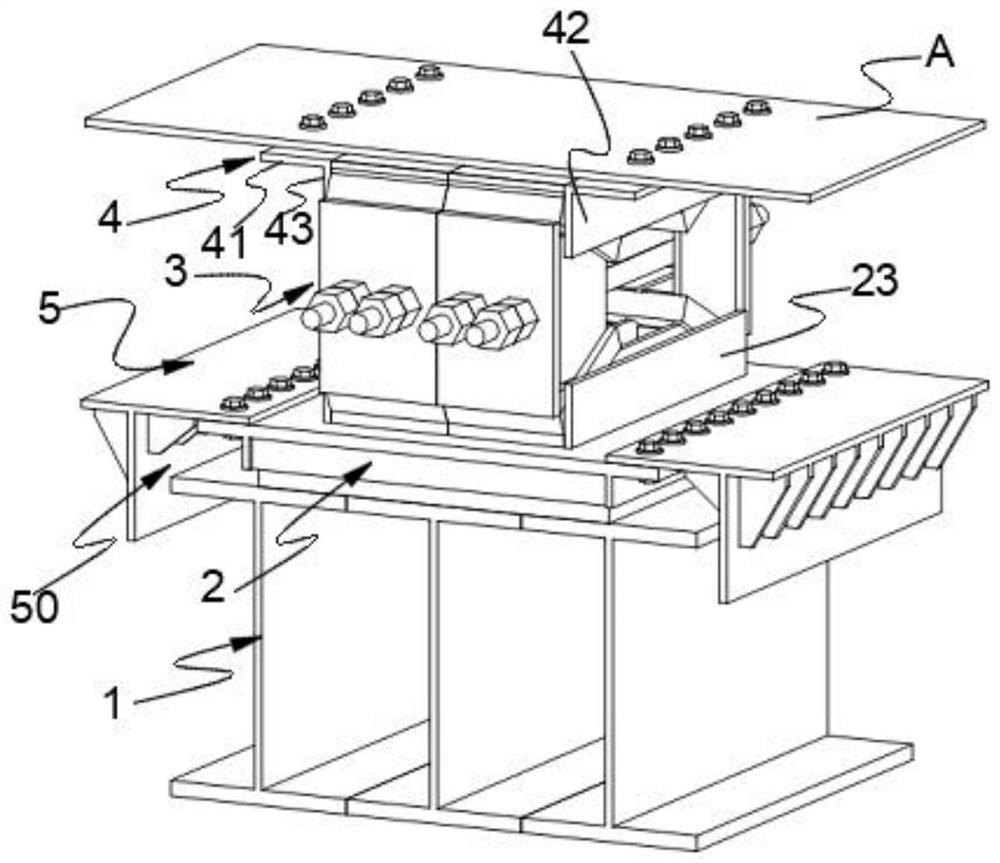

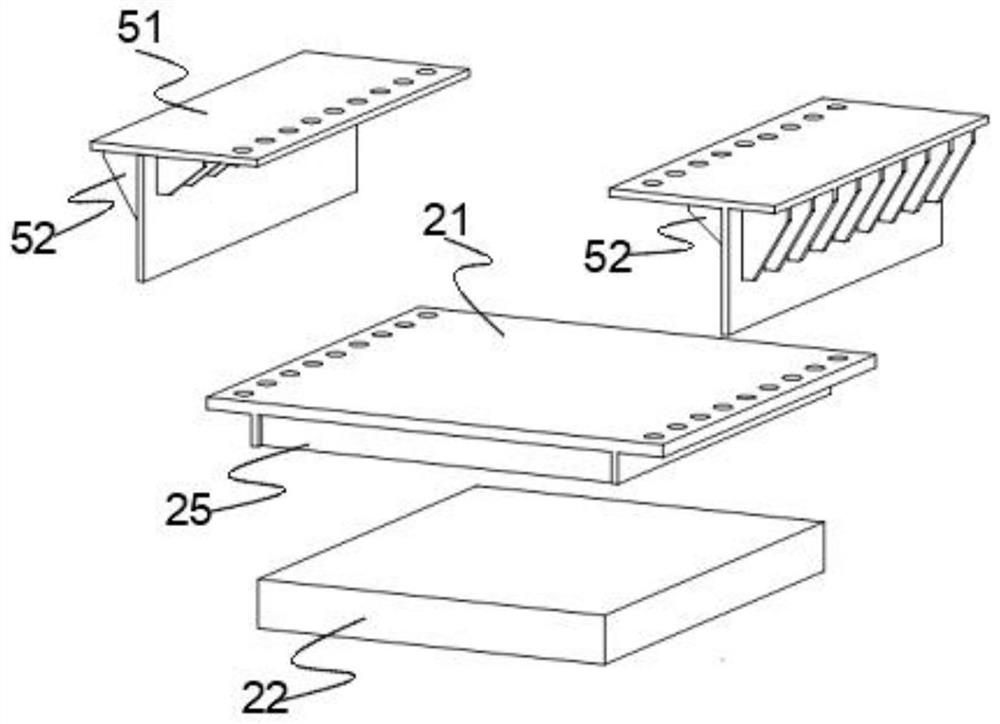

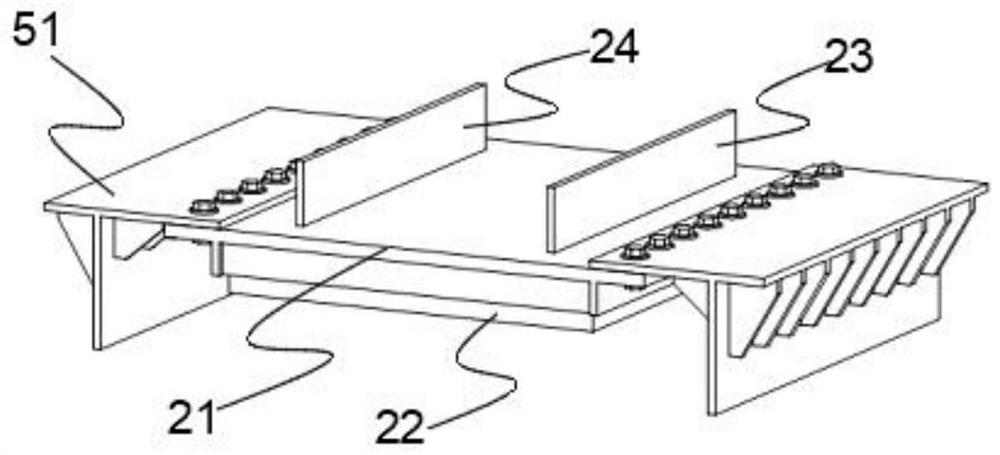

[0059] A bridge towing traction system

[0060] refer to Figure 11 to Figure 16 , a bridge towing and traction system provided in this embodiment, including: a temporary support 61 on shore, a temporary support 62 in water, a main pier 63, an anti-sliding pier 64, a first slideway part, a second slideway part and a sliding support part .

[0061] The shore temporary support 61 and the main pier 63 arranged on the bank are used to support the first slideway part, and the temporary support 62 in the water, the main pier 63 and the anti-skid pier 64 are used to support the second slideway part, and the first slideway part is arranged on the water. The slideway provided by the track part is docked with the slideway provided by the second slideway part to form a dragging slideway.

[0062] The sliding support part is slidably arranged on the dragging slideway. In this way, when the steel structure bridge needs to be dragged, the steel structure bridge can be supported on the sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com