Process for cascade leaching of ammonia nitrogen in ionic rare earth tailings

An ionic rare earth, leaching technology, applied in the direction of improving process efficiency, can solve problems such as ammonia nitrogen tailing, and achieve the effects of low production cost, low impurity content, and high rare earth leaching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

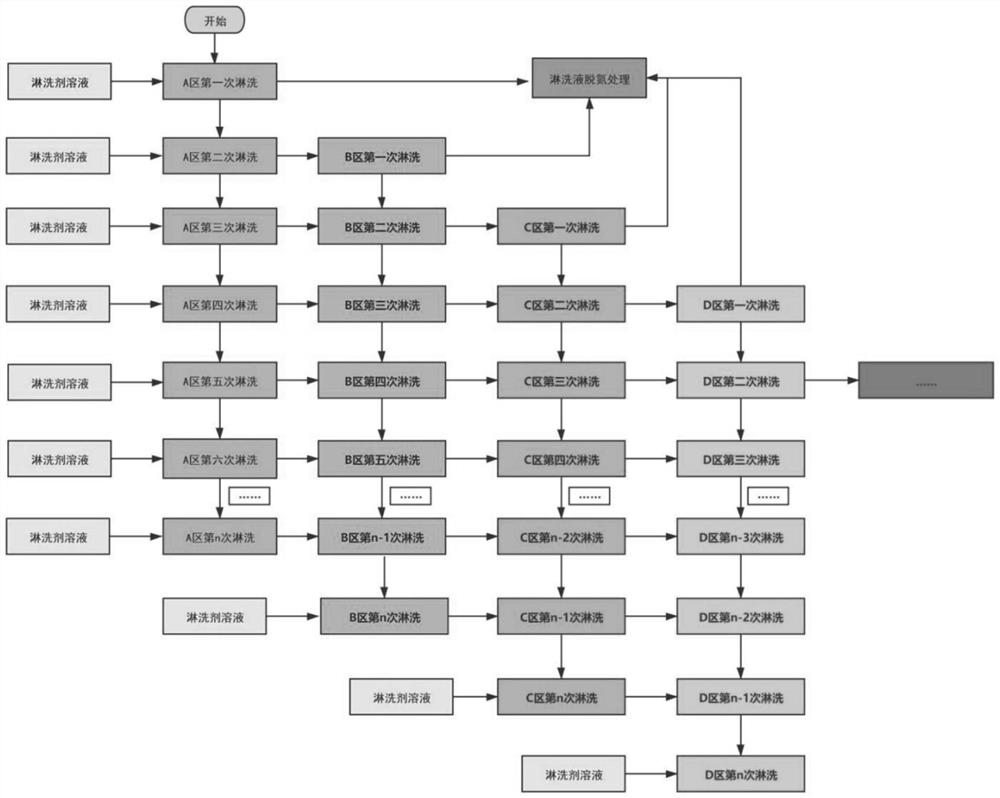

Method used

Image

Examples

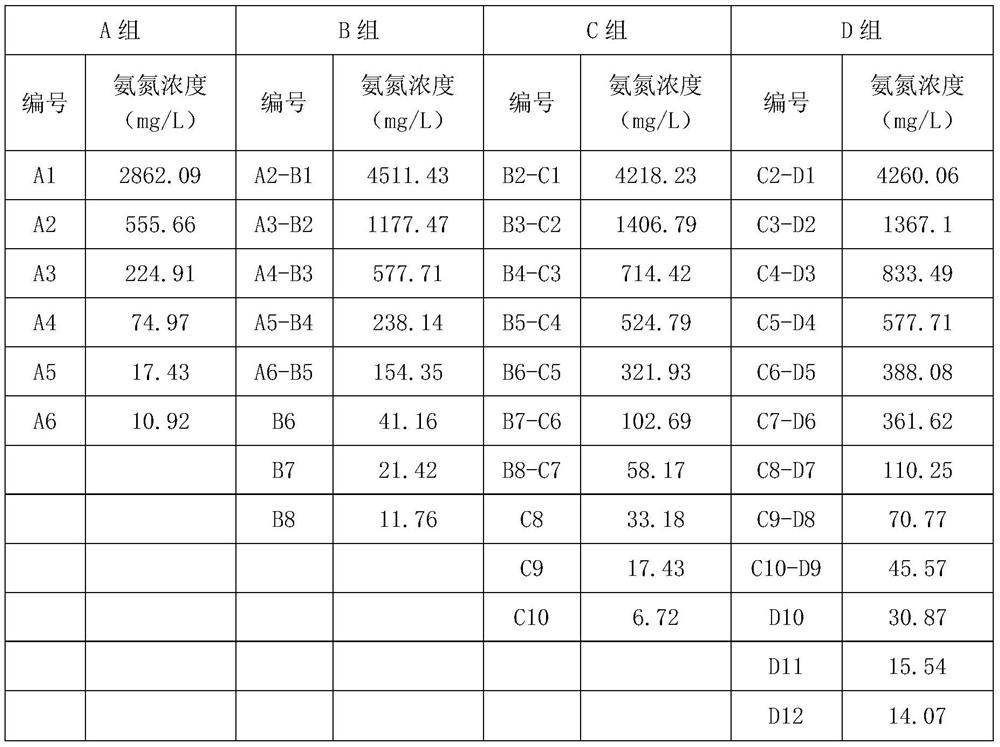

Embodiment 1

[0037] Ammonium sulfate is used as a leaching agent to simulate the cascade leaching of ionic rare earth tailings. The experimental process includes the following steps:

[0038] (1) Weigh a certain amount of ion-type rare earth tailings ore soil, smash it through a 20-mesh sieve, mix it evenly, weigh 40g of the treated ion-type rare earth tailings ore soil and fill it into the same four exchange columns Inside, numbered A / B / C / D, add 20ml of deionized water to moisten the ore soil to facilitate subsequent full rinsing;

[0039] (2) Add a magnesium sulfate solution with a mass concentration of 2% to the A column for gradation washing, each injection volume is 50ml, and the liquid collection volume is 50ml, numbered A1, A2, A3, ..., respectively measure the eluate When the concentration of ammonia nitrogen in the eluent is less than 15mg / L, stop injecting;

[0040] (3) According to the cascade elution process, the second eluent of column A is used as the first eluent of column B ...

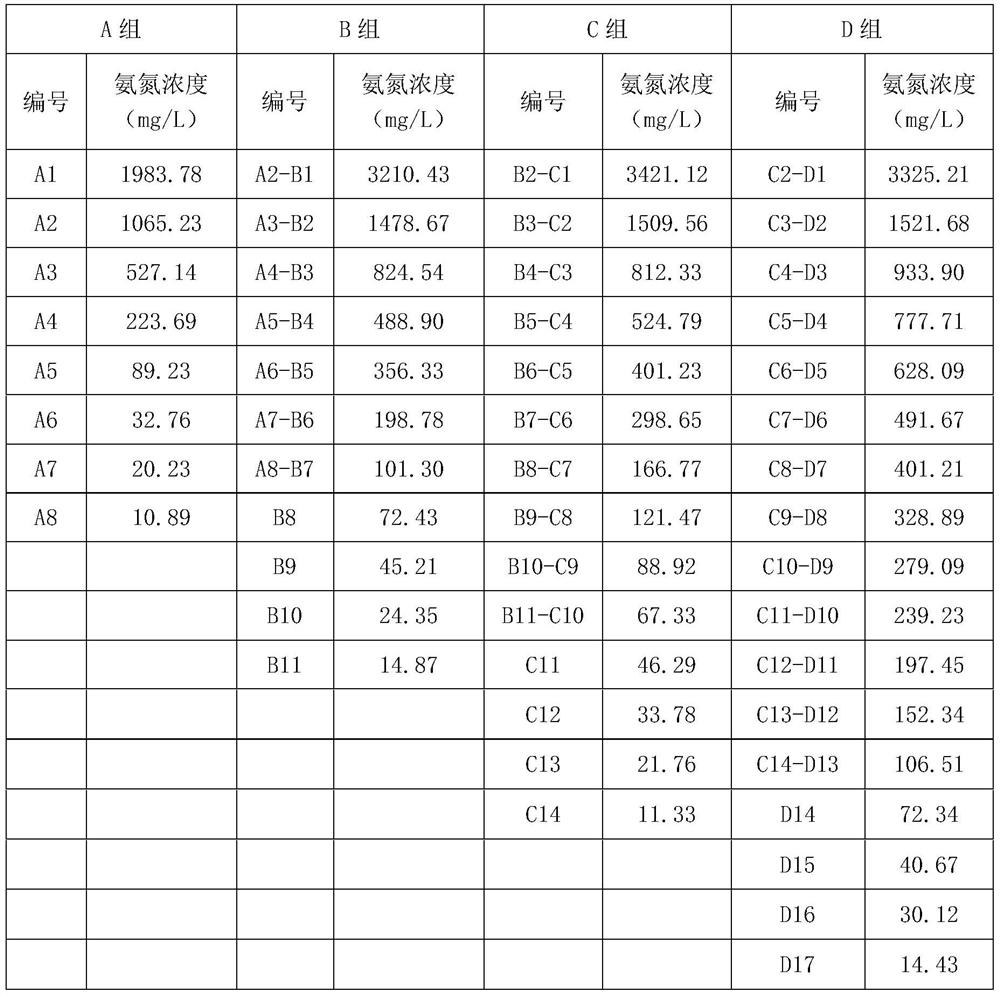

Embodiment 2

[0046] Potassium chloride is used as a leaching agent to simulate the cascade leaching of ionic rare earth tailings. The experimental process includes the following steps:

[0047] (1) Weigh a certain amount of ion-type rare earth tailings ore soil, smash it through a 20-mesh sieve, mix evenly, weigh 40g of the treated ion-type rare earth tailings ore soil and fill it into the same four exchange columns Inside, numbered A / B / C / D, add 20ml of deionized water to moisten the ore soil to facilitate subsequent full rinsing;

[0048] (2) Add a potassium chloride solution with a mass concentration of 2% in the A column for leaching in several stages, each injection volume is 50ml, and the liquid collection volume is 50ml, numbered A1, A2, A3, ..., measure the leaching respectively When the concentration of ammonia nitrogen in the eluent is less than 15mg / L, stop injecting;

[0049] (3) According to the cascade elution process, the second eluent of column A is used as the first eluent...

Embodiment 3

[0055] Ferric sulfate is used as a leaching agent to simulate the cascade leaching of ionic rare earth tailings. The experimental process includes the following steps:

[0056] (1) Weigh a certain amount of ion-type rare earth tailings ore soil, smash it through a 20-mesh sieve, mix evenly, weigh 40g of the treated ion-type rare earth tailings ore soil and fill it into the same four exchange columns Inside, numbered A / B / C / D, add 20ml of deionized water to moisten the ore soil to facilitate subsequent full rinsing;

[0057] (2) Add a ferric sulfate solution with a mass concentration of 2% in the A column for gradation washing, each injection volume is 50ml, and the liquid collection volume is 50ml, numbering A1, A2, A3,..., measure the eluent respectively When the concentration of ammonia nitrogen in the eluent is less than 15mg / L, stop injecting;

[0058] (3) According to the cascade elution process, the second eluent of column A is used as the first eluent of column B for el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com