Open-type scrap steel heating device and method capable of impurity pretreatment

A heating device and pretreatment technology, which is applied in the field of metal smelting, can solve problems such as explosions and kiln suffocation, and achieve the effects of protecting the environment, preventing gas accumulation, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

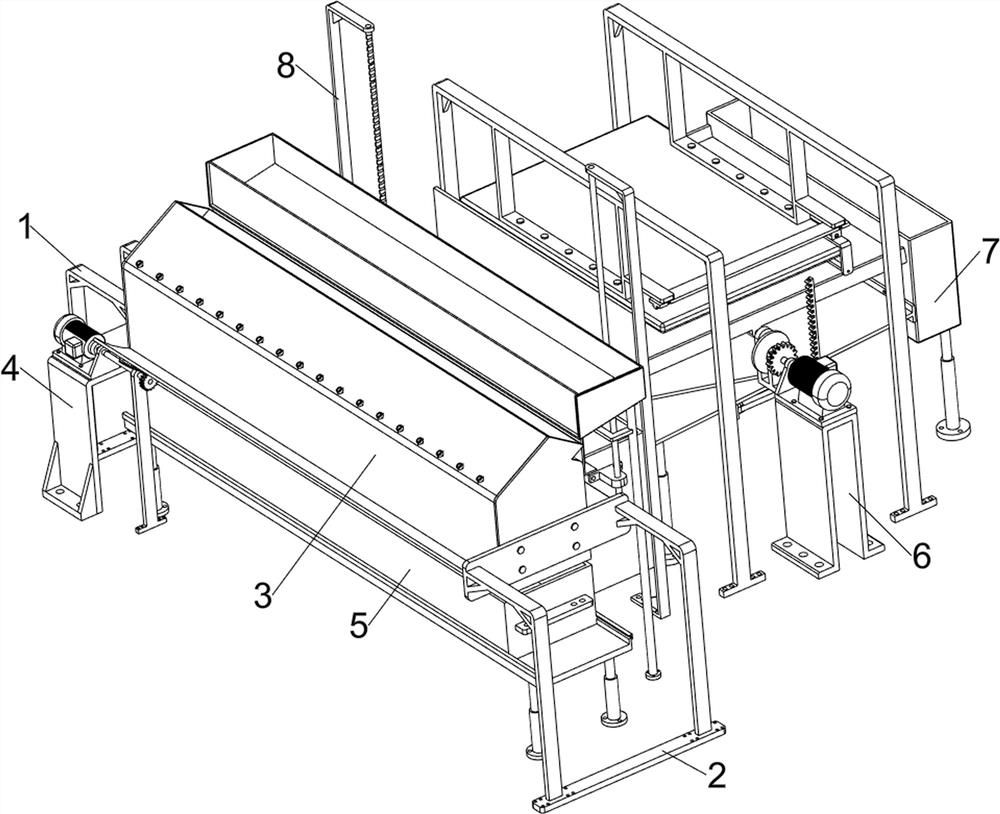

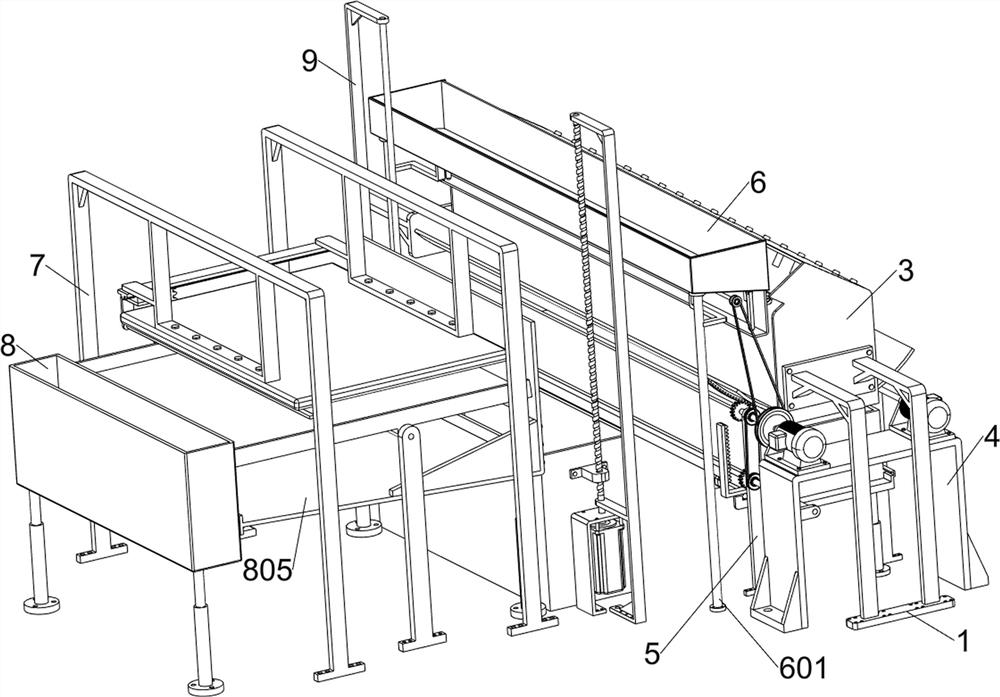

[0046] An open scrap heating device for sundry pretreatment, such as Figure 1-3 As shown, it includes a first connecting frame 1, a second connecting frame 2 and a scrap steel heating mechanism 3; the second connecting frame 2 is arranged behind the first connecting frame 1; the first connecting frame 1 and the second connecting frame 2 are connected with a The scrap steel heating mechanism 3 is used for heating the scrap steel.

[0047] When using the new furnace-free kiln scrap steel explosion-proof safety heating device, first install the device on the level ground, then turn on the power and adjust the operating status of the device, and then cut the head, tail and chips of the pretreated steel Steel scraps such as scraps and scraps are added to the open heating container in the scrap heating mechanism 3, and the scrap steel is heated by the scrap heating mechanism 3. The present invention adopts an open scrap steel heating container, which overcomes the need to heat the ...

Embodiment 2

[0049] On the basis of Example 1, such as Figure 4-7 As shown, the scrap steel heating mechanism 3 includes a heating box 301, a first igniter 302, a second igniter 303, a first arc baffle 304 and a second arc baffle 305; the first connecting frame 1 and the second The upper part of the connecting frame 2 is connected with a heating box 301 by bolts; the upper left part of the heating box 301 is connected with a plurality of first igniters 302; the upper right part of the heating box 301 is connected with a plurality of second igniters 303; The first arc baffle 304 is slidingly connected; the lower right part of the heating box 301 is slidingly connected with the second arc baffle 305, and the left part of the second arc baffle 305 is in contact with the right part of the first arc baffle 304 ; The heating box 301, the first arc baffle 304 and the second arc baffle 305 form a heating chamber.

[0050] The scrap steel heating mechanism 3 also includes a first chute 305a, a T-...

Embodiment 3

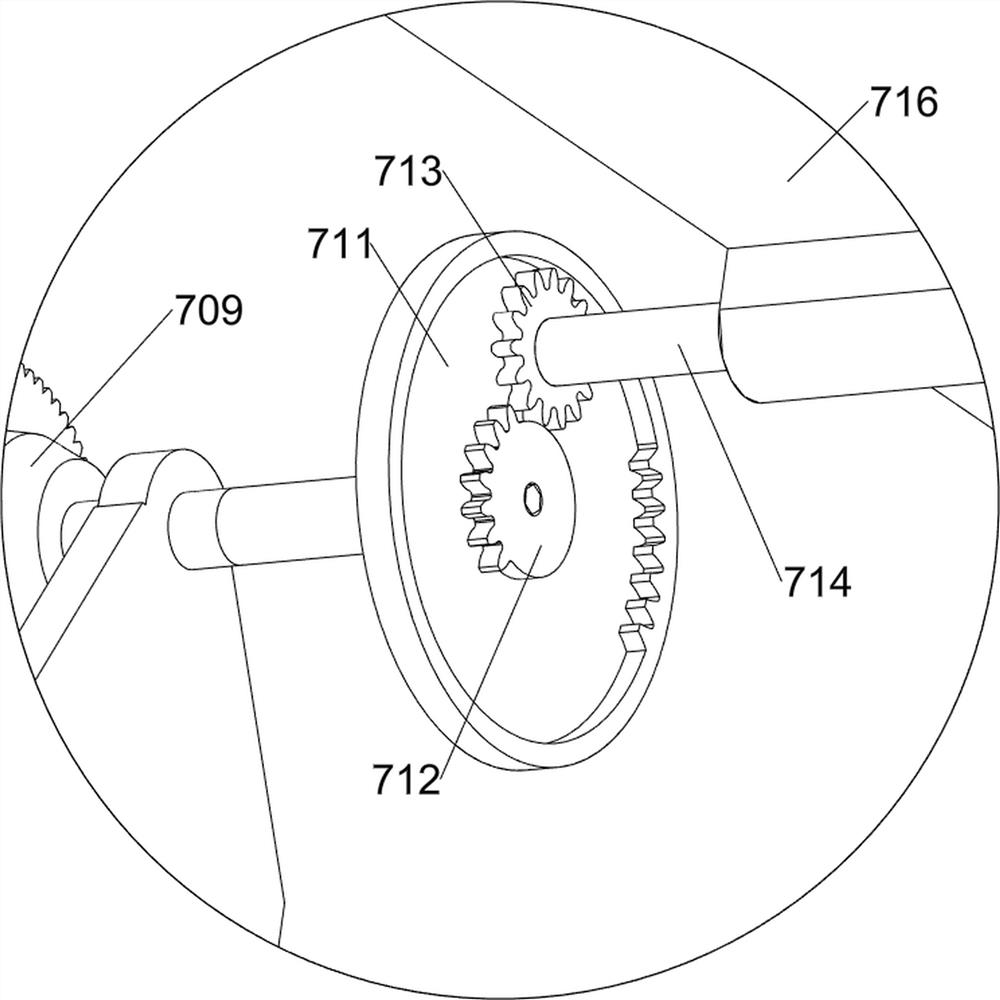

[0055]On the basis of Example 2, such as Figure 8-11 As shown, a collection lifting mechanism 5 is also included, and a collection lifting mechanism 5 is arranged below the heating box 301, and the collection lifting mechanism 5 connects the mounting frame 401 and the first rotating rod 403; the collection lifting mechanism 5 includes a second connecting plate 501 , the third rotating rod 502, the first transmission wheel 503, the second transmission wheel 504, the third gear 505, the first telescopic support column 506, the linear slide rail 507, the second chute 507a, the first telescopic member 508, the third Connecting plate 509, the first L-shaped plate 510, the first rack 511 and the first collection box 512; the rear part of the outer surface of the first rotating rod 403 is rotatably connected with the second connecting plate 501; the middle part of the second connecting plate 501 is rotatably connected with The third rotating rod 502, and the outer front part of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com