Process for manufacturing three-dimensional circuit through laser etching and plastic surface carbonization

A laser etching and surface fabrication technology, applied in the field of circuit manufacturing, can solve problems such as difficulty in meeting high-standard manufacturing requirements for mobile phone antennas, complex laser parameter debugging, and reduced laser processing efficiency, achieving good toughness, improved yield, and injection molding cracks. low risk effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

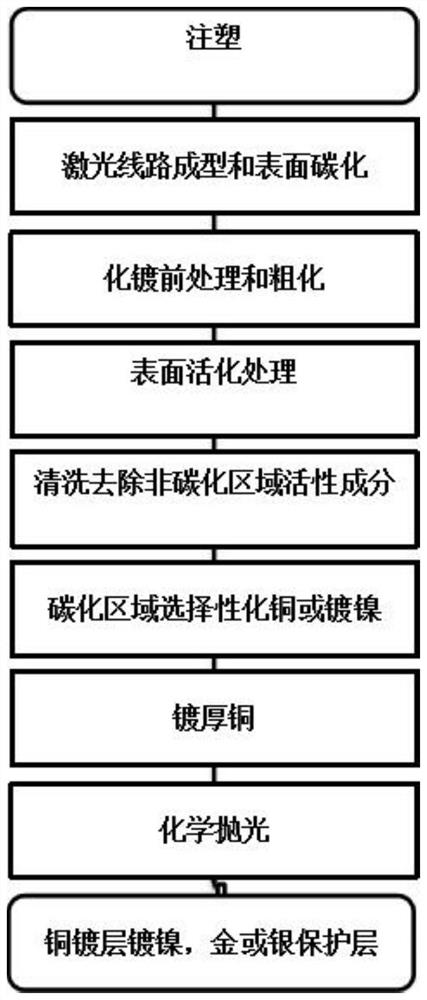

[0064] Such as Figure 1-9 As shown, the embodiment of the present invention provides a process for making a three-dimensional circuit by laser etching and carbonizing the plastic surface, including the following specific steps:

[0065] S1. The plastic substrate carrying the circuit is made by injection molding. The plastic body is often not only the carrier of the circuit but also the structural component of the product design. Because of this, this process can provide great flexibility for product design. In order to ensure the subsequent plating effect, different injection molding materials need to use different combinations of laser parameters according to the actual effect, and the roughening potion and process parameters during chemical roughening also need to make necessary adjustments;

[0066] S2. The graphics of the circuit is processed on the surface of the plastic part by laser engraving, and the carbonization effect of the circuit area on the plastic surface is r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com