Lithium battery recycling equipment with disassembling function

A technology for recycling equipment and lithium batteries, which is applied in the field of lithium battery recycling equipment with dismantling function, which can solve the problems of physical injury, troublesome operation, and large debris particles, so as to reduce damage, reduce energy consumption, and avoid deflection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

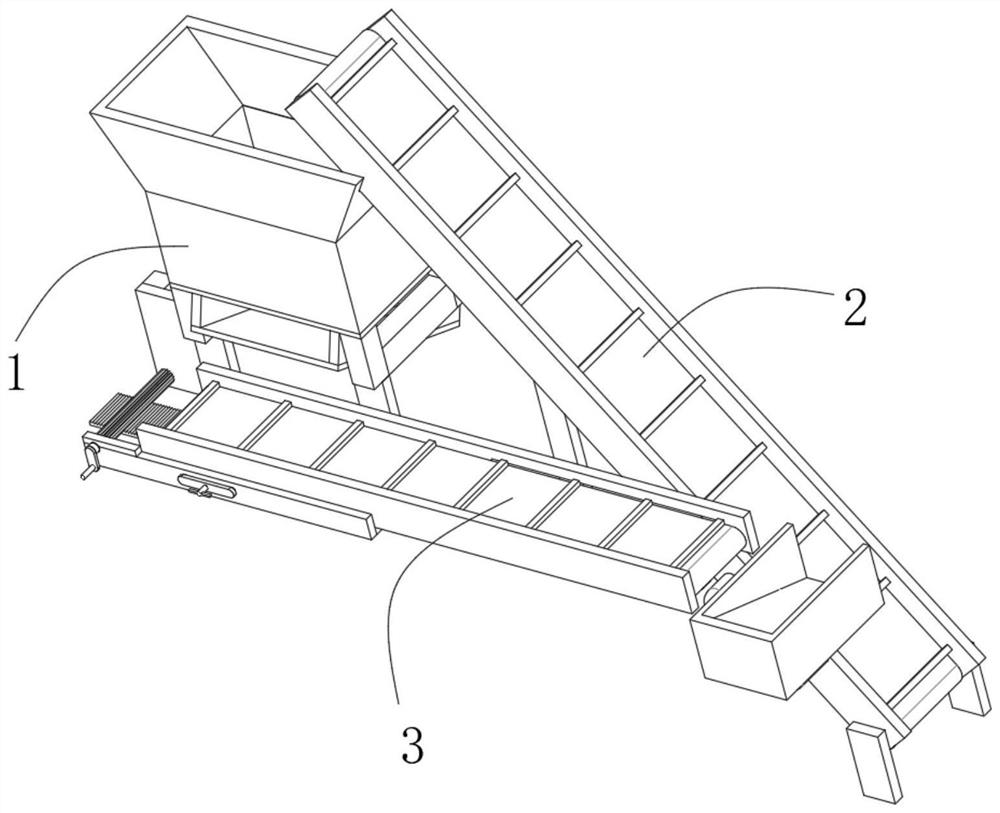

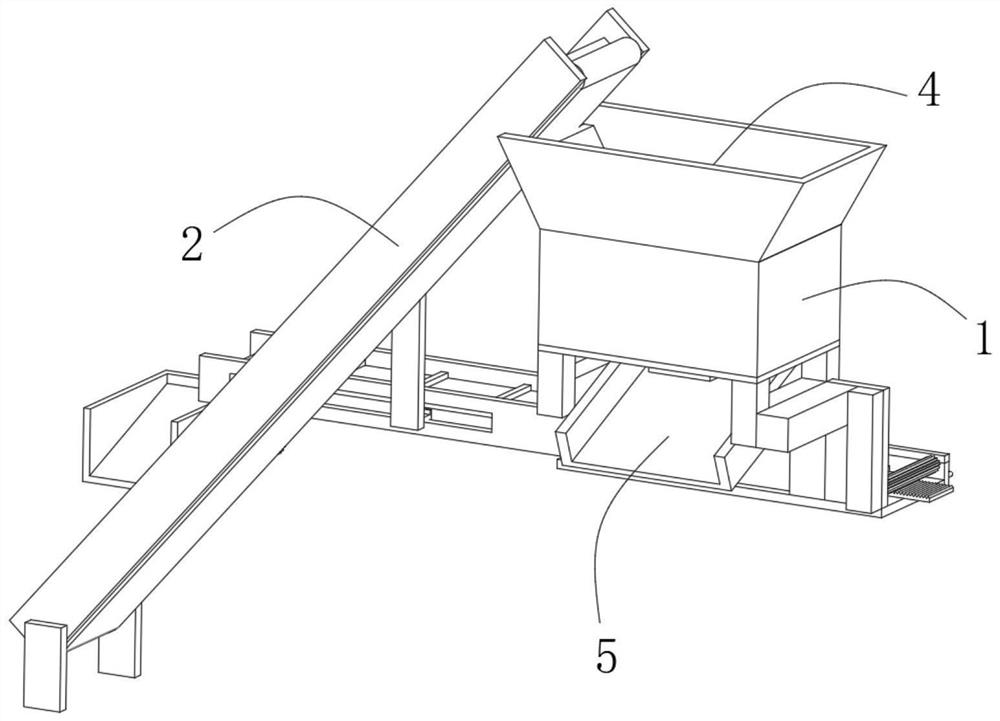

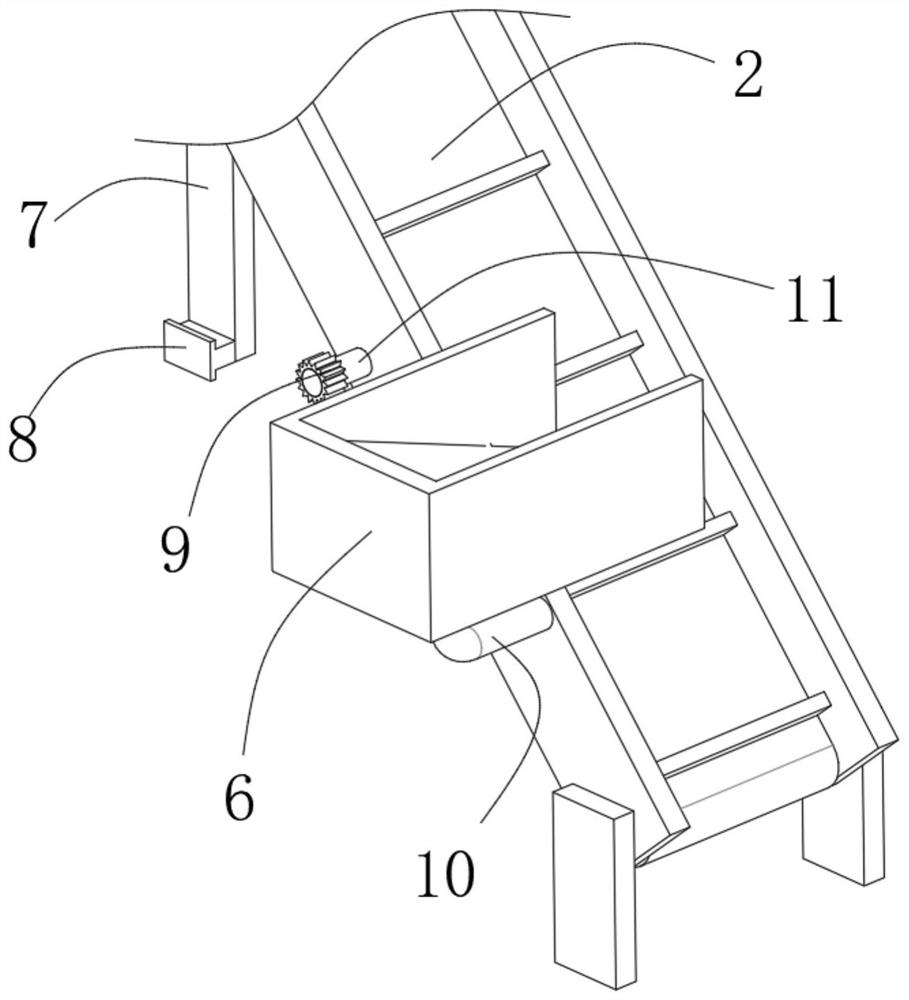

[0034] like Figure 1-8 A lithium battery recovery device with a dismantling function is shown, including;

[0035] The primary crushing bin 1, the side of the primary crushing bin 1 is fixedly installed with the first conveyor belt 2, the back of the primary crushing bin 1 is provided with the second conveyor belt 3, the second conveyor belt 3 is slidably connected to the side of the first conveyor belt 2, the second An inclined hopper 6 is fixedly installed on the outer surface of the first conveyor belt 2, and the end of the second conveyor belt 3 is directly above the inclined hopper 6. The bottom of the primary crushing bin 1 is provided with a rotating material guide plate 5, and the end of the rotating material guide plate 5 Facing the second conveyor belt 3, the outer surfaces of the first conveyor belt 2 and the second conveyor belt 3 are provided with anti-skid bars;

[0036] Drive the rotating rod 21, the side of the driving rotating rod 21 is fixedly equipped with...

Embodiment 2

[0040] like Figure 1-8 A lithium battery recovery device with a dismantling function is shown, including;

[0041] The primary crushing bin 1, the side of the primary crushing bin 1 is fixedly equipped with a first conveyor belt 2, the back of the primary crushing bin 1 is provided with a second conveyor belt 3, and the second conveyor belt 3 is slidably connected to the side of the first conveyor belt 2. An inclined hopper 6 is fixedly installed on the outer surface of the first conveyor belt 2, and the end of the second conveyor belt 3 is directly above the inclined hopper 6. The bottom of the primary crushing bin 1 is provided with a rotating material guide plate 5, and the end of the rotating material guide plate 5 Facing the second conveyor belt 3;

[0042] Drive the rotating rod 21, the side of the driving rotating rod 21 is fixedly equipped with a crank handle 20, the outer surface of the driving rotating rod 21 is fixedly sleeved with a third gear 22, the third gear ...

Embodiment 3

[0046] like Figure 1-8 A lithium battery recovery device with a dismantling function is shown, including;

[0047] The primary crushing bin 1, the side of the primary crushing bin 1 is fixedly equipped with a first conveyor belt 2, the back of the primary crushing bin 1 is provided with a second conveyor belt 3, and the second conveyor belt 3 is slidably connected to the side of the first conveyor belt 2. An inclined hopper 6 is fixedly installed on the outer surface of the first conveyor belt 2, and the end of the second conveyor belt 3 is directly above the inclined hopper 6. The bottom of the primary crushing bin 1 is provided with a rotating material guide plate 5, and the end of the rotating material guide plate 5 Facing the second conveyor belt 3;

[0048] Drive the rotating rod 21, the side of the driving rotating rod 21 is fixedly equipped with a crank handle 20, the outer surface of the driving rotating rod 21 is fixedly sleeved with a third gear 22, the third gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com