Mechanized production equipment of clow chain

A technology for manufacturing equipment and claw chains, applied in the field of manufacturing equipment for jewelry claw chains, can solve the problems of slow production speed, unstable quality, rough appearance, etc., and achieve the effects of improving quality, improving labor efficiency, and improving user comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

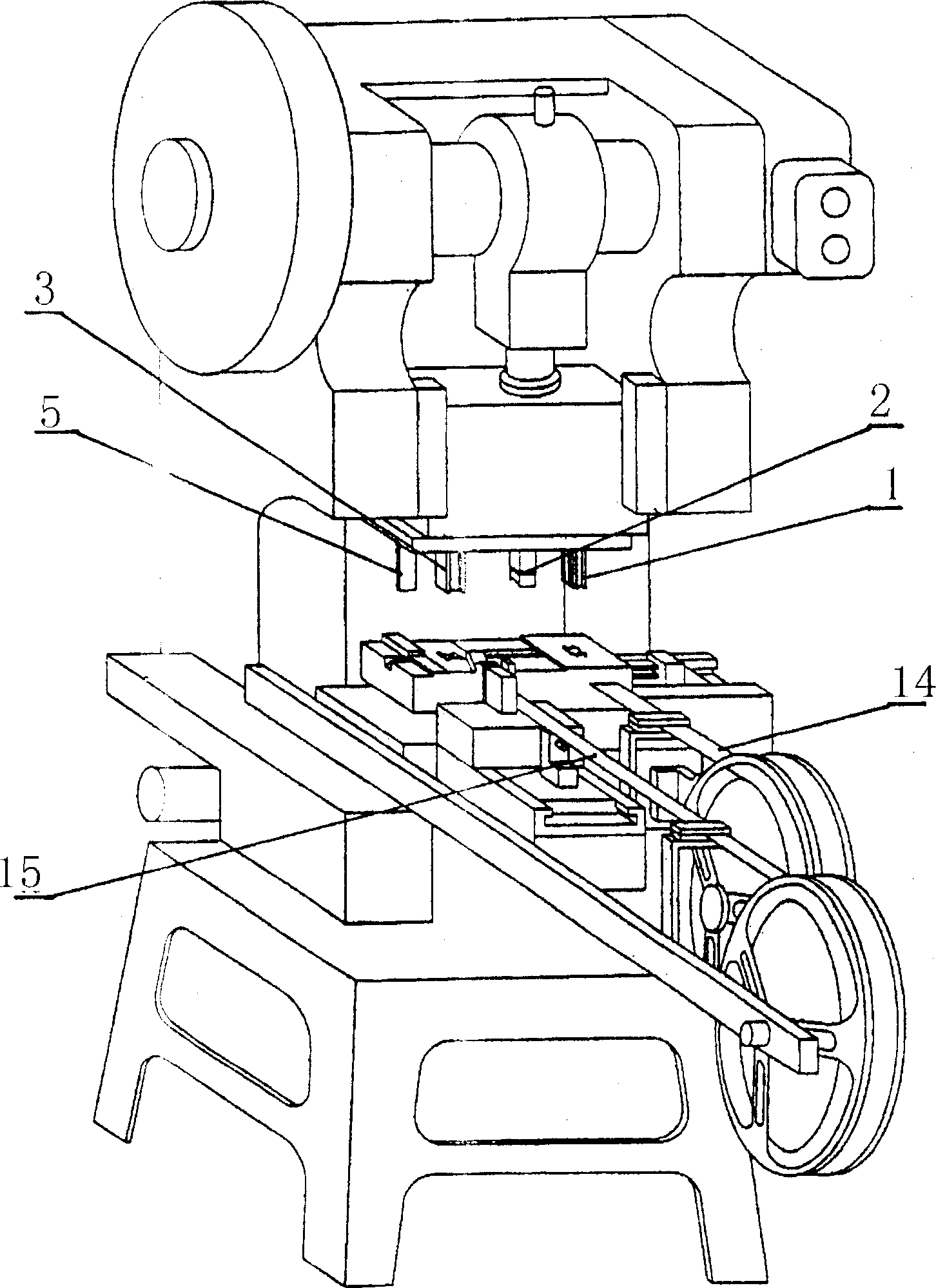

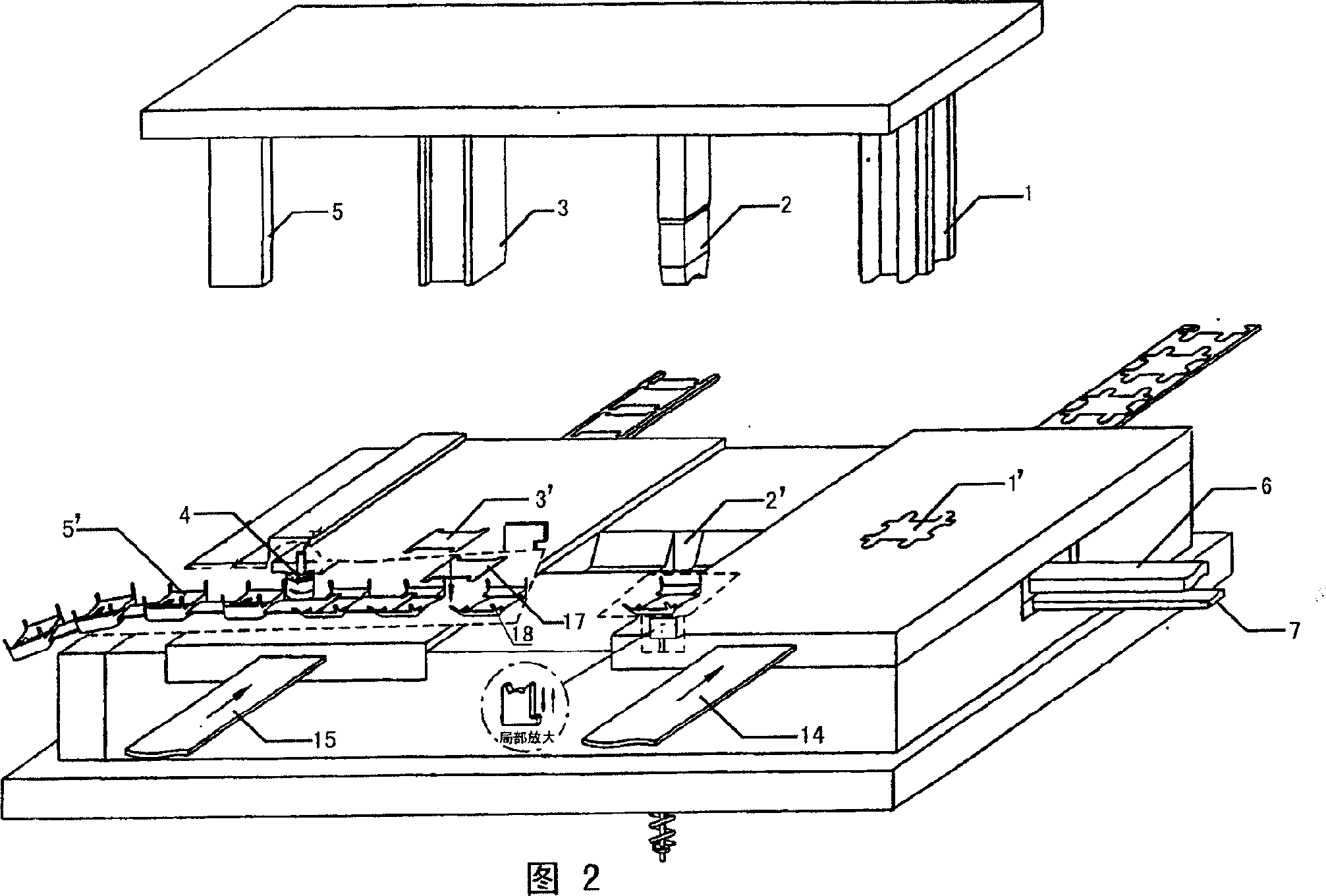

[0037] Referring to the attached picture:

[0038] The invention includes a machine base, a transmission mechanism, a stamping mechanism,

[0039] Including: Cutting station for punching down the link flat piece with gem claw toe and connecting piece lock on the copper strip, pressing station for flanging the chain link flat piece around, punching down the connection from the copper strip The joint piece is placed on two adjacent chain link blanks, the extrusion station presses the chain link blank from both sides of the conveying trough to close the lock buckle on the chain link blank, and flat presses the chain link to shape it forming station;

[0040] The mold bed is provided with a longitudinal chain link flat sheet conveying groove 8 and a chain link embryo conveying groove 9. The chain link flat sheet conveying groove 8 is located above the chain link embryo conveying groove 9, and the chain link flat sheet conveying groove 8 and the chain The push rods 6 and 7 driven...

Embodiment 2

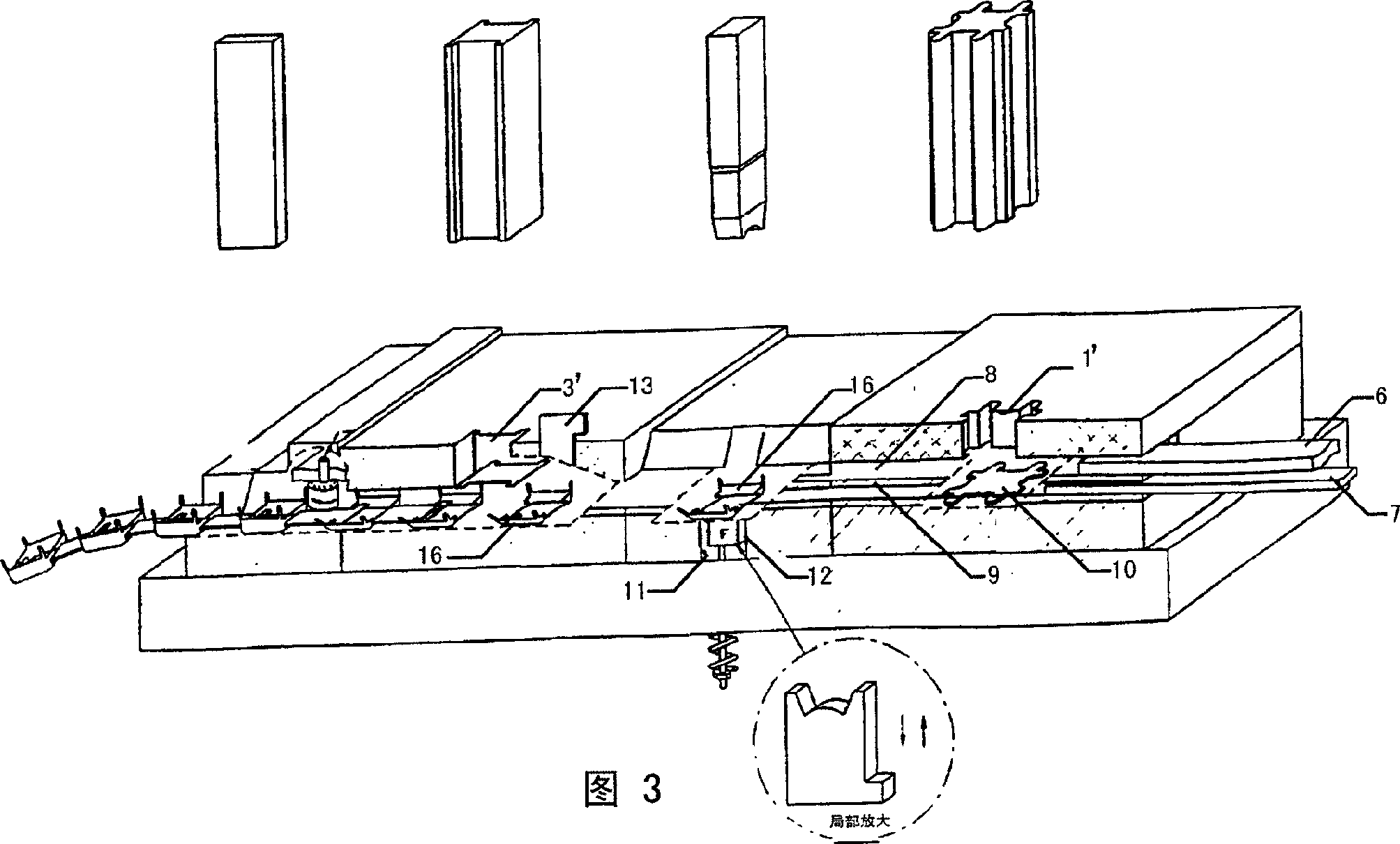

[0056] Referring to the attached picture:

[0057] On the basis of Example 1, a pillow 12 is provided at the bottom of the pressing die, the left and right walls of the pillow 12 gradually shrink from top to bottom, and the upper end surface of the pillow is an arc of an upward bow. Shape, the bottom support spring of pillow pad, the shape of press-shaped positive mold is corresponding with female mold.

[0058]The function of setting the pillow is to make the flanging at the bottom of the chain link rounded, which increases the comfort of use and the delicacy of the appearance.

Embodiment 3

[0060] Referring to the attached picture:

[0061] On the basis of Example 1, a forming station is set. A flat pressing die is set on the forming station to flat press the chain link to shape it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com