Self-waterproof structure for concrete side wall of non-fat-groove underground engineering and construction method

A technology for underground engineering and waterproof structures, applied to building components, building structures, wine cellars, etc., can solve problems such as shrinkage and cracking of the main concrete structure, improve the overall tensile performance and sag performance, reduce self-shrinkage, The effect of expansion product stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

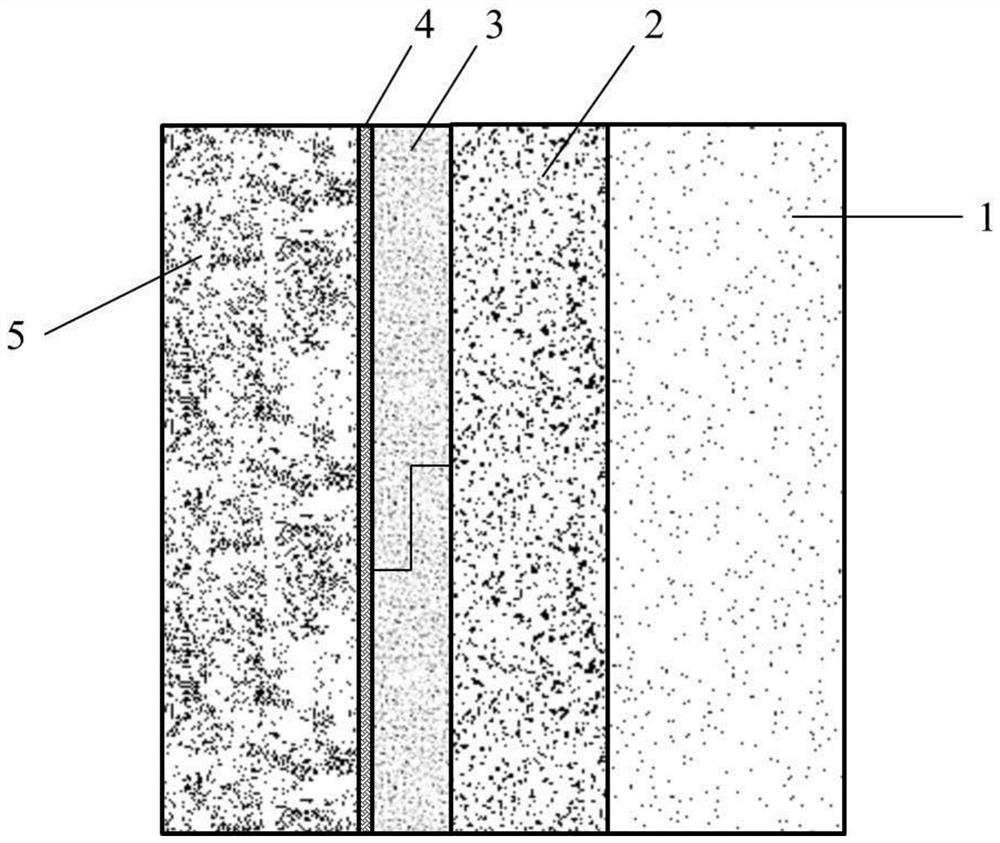

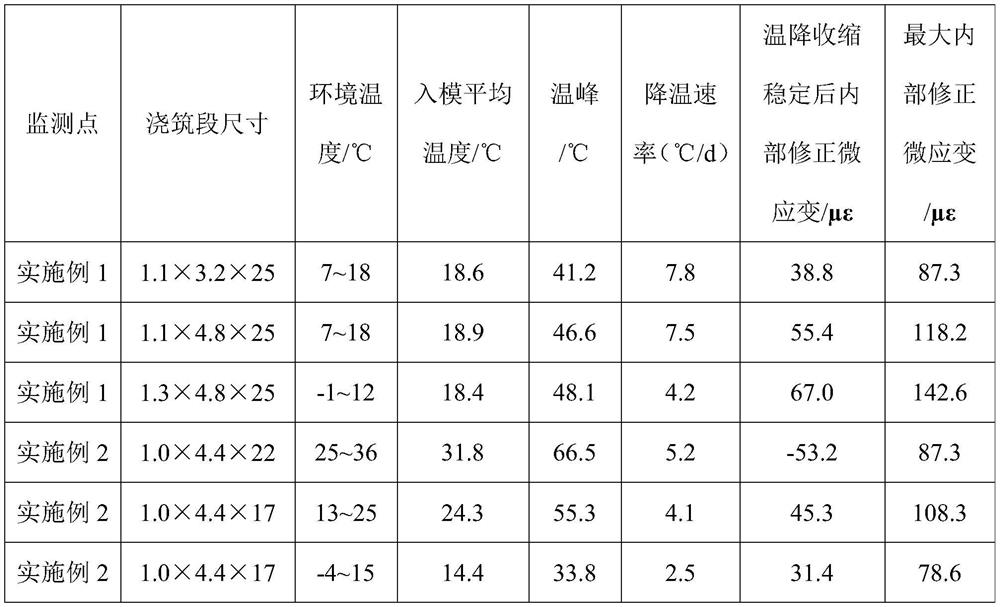

[0035] For a provincial highway tunnel project in Wuxi, the main body of the open section of the lake east section is supported by SMW piles, and the main body of the buried section is supported by ground connection walls, concrete support beams and steel supports, all of which are construction techniques without fertilizer tanks. Waterproof grade two and above, concrete grade C40P8, side wall thickness 1.1-1.5m, wall height 2.0-8.8m, length about 600m, construction season is winter, daily average temperature ≤10℃. The self-waterproof structure of this section of the side wall includes a support structure, a modified EPE pearl foam board, and a self-waterproof concrete layer. It is bonded on the surface of the modified EPE pearl foam board, and the surface of the non-woven fabric is coated with a layer of cement-based permeable crystalline waterproof paint.

[0036] The construction method steps of the self-waterproof structure of the side wall are as follows:

[0037] S1. Af...

Embodiment 2

[0047] For a lake-crossing tunnel project of an urban trunk line in Suzhou, the main body of the open section in the east of the lake is supported by SMW piles, and the main body of the buried section is supported by ground connection walls, concrete support beams and steel supports. Grade II and above, concrete grade C35P8, side wall thickness 0.7-1.0m, wall height 2.2-6.8m, length about 1000m, construction seasons are summer, autumn and winter, average daily temperature in summer ≥ 25°C, average daily temperature in autumn 10-25°C ℃, and the daily average temperature in winter is ≤10℃. The self-waterproof structure of this section of the side wall includes a support structure, a modified EPE pearl foam board, and a self-waterproof concrete layer. It is bonded on the surface of the modified EPE pearl foam board, and the surface of the non-woven fabric is coated with a layer of cement-based permeable crystalline waterproof paint.

[0048] The construction method steps of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com