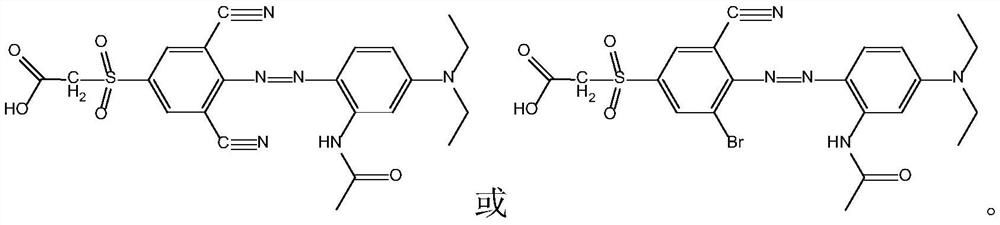

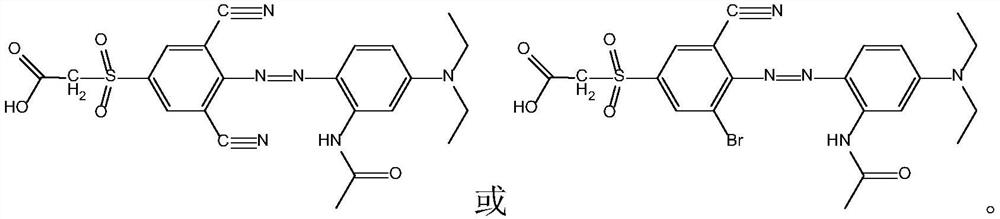

Red-light blue liquid dye composition and application thereof in textile dyeing and printing

A technology of liquid dyes and compositions, which is applied in textiles and papermaking, dyeing methods, organic dyes, etc., and can solve the problems of unsuitable and unsuitable dye reflection wavelengths, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] (1) Preparation of hydrophilic components

[0048] In a 100 ml three-mouth flask, 21.96 mL (0.4 mol) was added to 5 ° C, cooled to 5 ° C, and the purity was slowly added to 70% (0.04004 mol) at 5 ° C, and slowly warmed to 70 At ° C, stirred for 30 min, cooled to 20 ° C or lower. 4-carboxylate-2,6-dibromoiline 16.4 g (0.04 mol) was gradually added between 15-20 ° C, and the wall was filled with 4.36 mL, 98% concentrated sulfuric acid (0.04 mol). Amine, combined into the reaction flask. Slowly warmed to 40 ° C, reacted 4-5h, until all dissolved, measure the end point of the diazonation (taking the two drops of diazo), and no precipitation precipitated, that is, the end point), after the reaction, cool stand-by;

[0049] (2) Preparation of intermediates containing carboxymesulfonyl hydrophilic component aliquots

[0050] In a 500 ml beaker, 3-acetamin-N, N-diethylideine was added 8.41 g (0.04 mol), 100 ml of water, and 3.44 ml of 3.44 ml (0.04 mol) was added dropwise to total ...

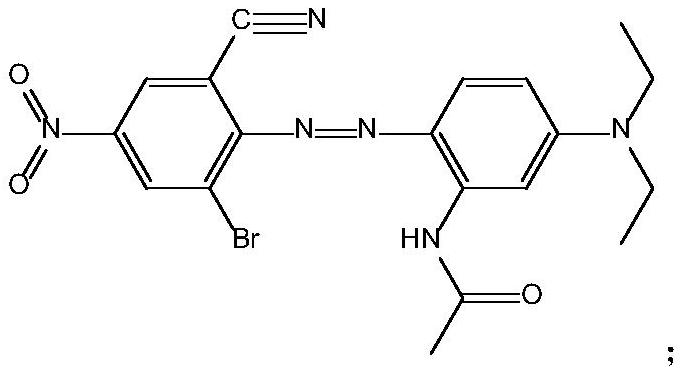

Embodiment 2

[0071] (1) Preparation of hydrophilic components

[0072] The method is the same as in Example 1.

[0073] (2) Preparation of intermediates containing carboxymesulfonyl hydrophilic component aliquots

[0074] Methods to Example 1

[0075] (3) Preparation of hydrophilic components of carboxylansulfonyl groups

[0076] In a 500 ml beaker, a hydrophilic component prepared from step (2) was added, 150 ml of water, 0.01 mL, 30% sodium hydroxide solution (0.04 mol) was added dropwise to complete dissolution.

[0077] 0.71 g of cyanide (8 mmol) and 20 mL of water were added to 500 ml of three flasks, 0.39 g, 12% cyanide aqueous solution (0.0132 mol), stirring the cyanide copper all dissolved. The mixture was added to 15 min, and the dissolved hydrophilic component alone was added to the reaction bottle, and after 15 min, 24.51 g, 12% cyanide aqueous solution (0.06 mol) was slowly added dropwise. After the drop is added, the reaction is stirred for 30 min. 4.4 g of ferricide (0.064 mol) w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com