Release agent heating and spraying device with good heat preservation effect

A technology of spraying device and mold release agent, applied in the field of bridge sleeper manufacturing, can solve the problems of slow heating of mold release agent, single means, influence of temperature control of mold release agent, etc., to improve heating uniformity, good thermal insulation effect, The effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

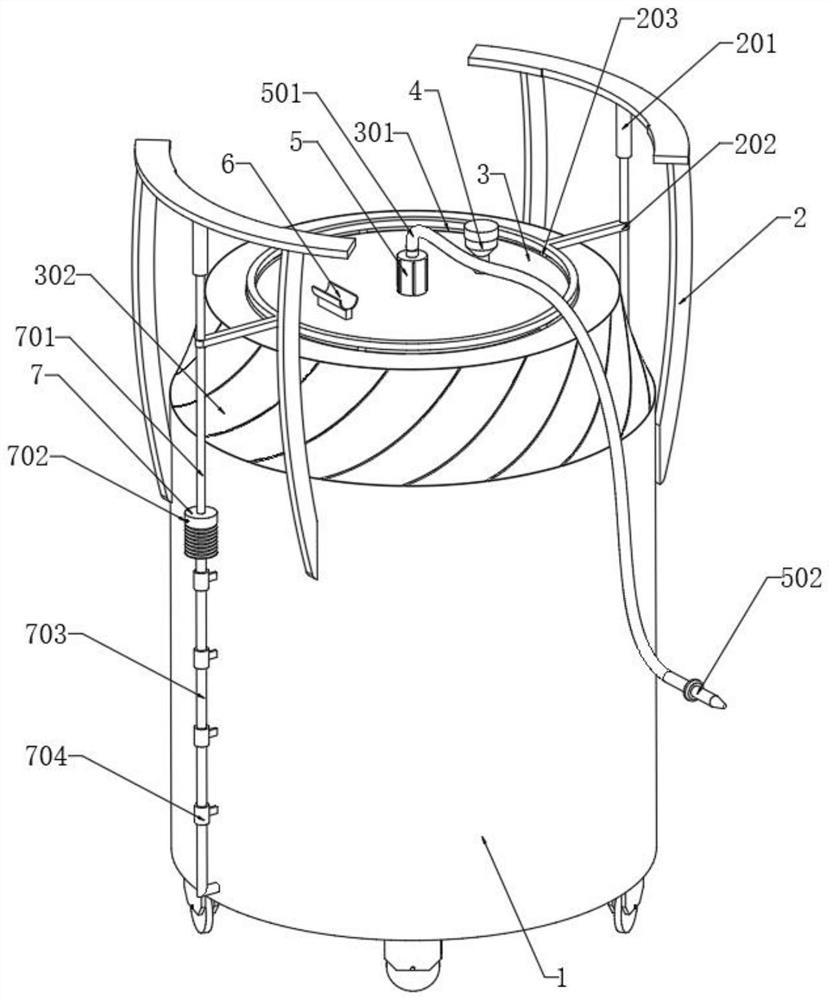

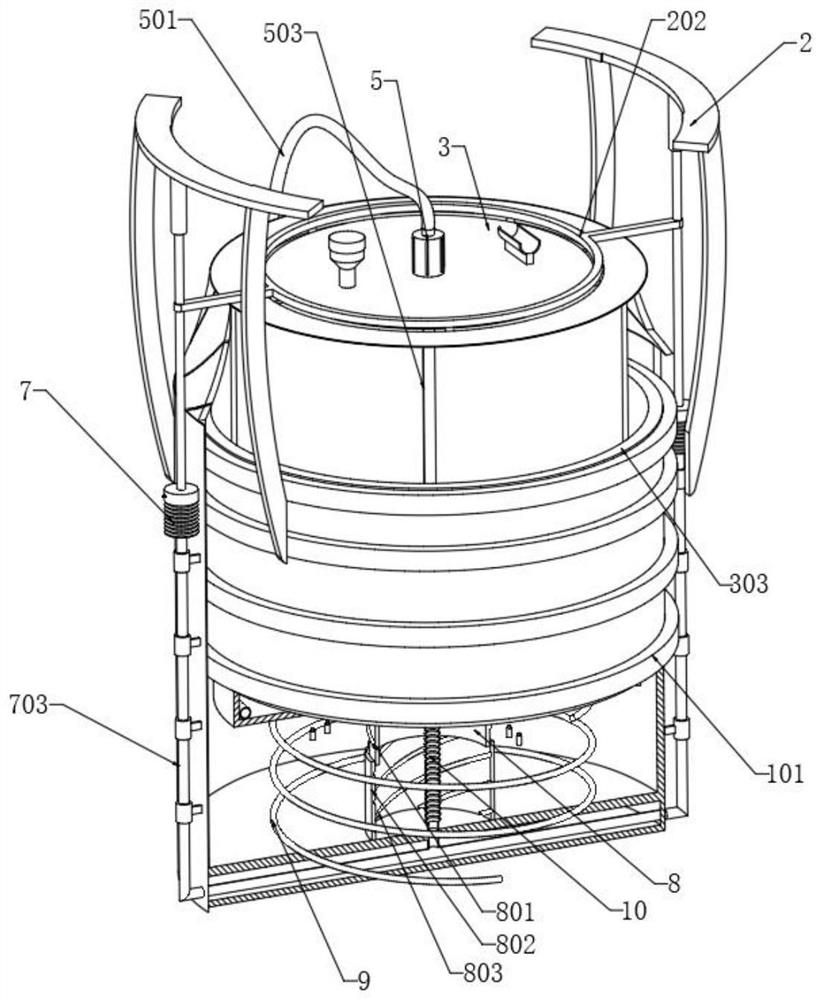

[0039] Such as Figure 1-Figure 7 As shown, a release agent heating spraying device with good thermal insulation effect includes an outer tank 1 with moving wheels arranged at the four corners of the outer wall of the bottom, an inner tank 3 is arranged inside the outer tank 1, and the bottom of the inner tank 3 and the outer tank 1 The opposite side of the inner tank 3 is equipped with a lifting and rotating mechanism, the top of the inner tank 3 and the opposite side of the outer tank 1 are equipped with a driving mechanism, and an elastic reset assembly is arranged between the top of the inner tank 3 and the outer tank 1, and the outer wall of the outer tank 1 Both sides are equipped with follow-up inflatable mechanism, the circumference outer wall of the inner tank 3 is fixedly equipped with heating components, the lifting and rotating mechanism includes the lifting cylinder 8 fixedly installed on the outer wall of the bottom of the inner tank 3, and the circumference outer...

Embodiment 2

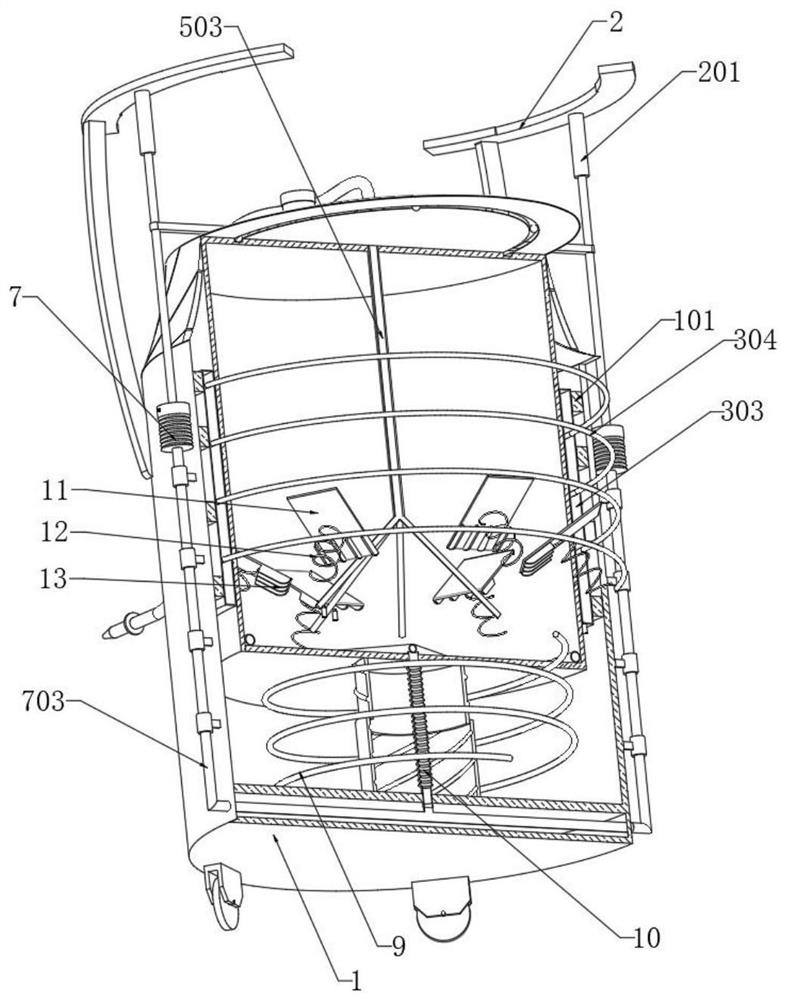

[0052] Based on the thermal spraying device for a release agent with good thermal insulation effect provided in the first embodiment of the present application, the second embodiment of the present application proposes another thermal spraying device for a release agent with good thermal insulation effect.

[0053] The second embodiment of the present invention will be further described below in conjunction with the drawings and implementation methods.

[0054] Such as Figure 8-Figure 9 As shown, the second embodiment also includes a plurality of movable dials 11 provided with a plurality of through-holes 17, and a plurality of petal-shaped arcs 18 are fixedly installed on the tops of the plurality of through-holes 17, and the suction pipe 503 One end is fixedly installed with the liquid-dialing lamination 20, and the bottom outer wall of the liquid-dialing lamination 20 is fixedly connected with a conical spring 21, and the other end of the conical spring 21 is fixedly insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com