Device and method for removing particulate matters in flue gas

A particulate matter and flue gas technology, applied in chemical instruments and methods, separation methods, combined devices, etc., can solve the problems of not eliminating pollutants, difficult to effectively remove condensable particulate matter, and small physical size, and the number of days to reach haze weather. The effect of reducing, reducing PM2.5 content, and removing the effect is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

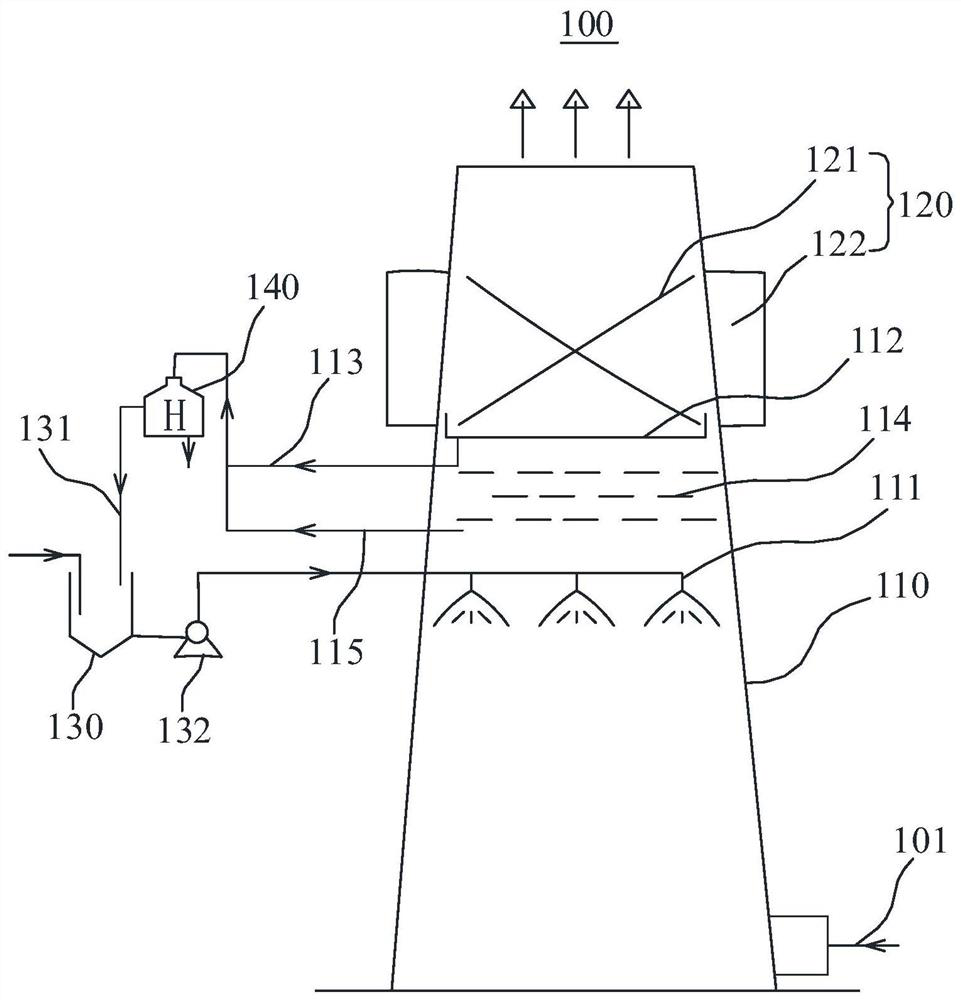

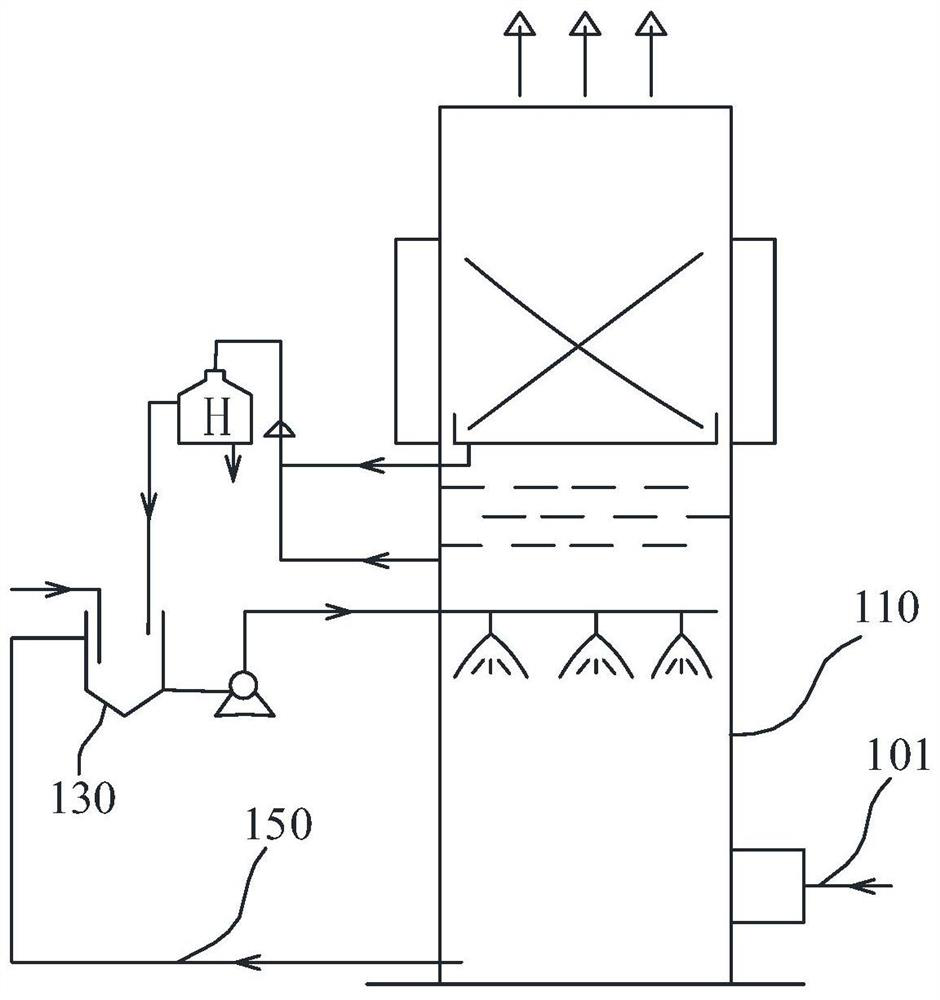

[0059] Such as figure 1 The device shown, process conditions: containing 1.7wt% magnetic seed spray liquid, the droplet particle size produced by the nozzle is not more than 20 μm, the field strength of the high-gradient magnetic separator 120 is 1.9T, and after running for 1.5 hours, the magnetic The medium is washed once, and the magnetic medium is bristle medium, and its material is mainly iron-cobalt alloy. The data before and after the treatment of particulate matter in flue gas are shown in Table 1.

[0060] Table 1 Situation before and after flue gas treatment

[0061] Test items Abbreviation before processing after treatment Removal rate filterable particles FPM 11.50mg / Nm 3

Embodiment example 2

[0063] Such as figure 1 The device shown, process conditions: containing 1.9% magnetic seed spray liquid, the droplet size produced by the nozzle is not greater than 20μm, the field strength of the high-gradient magnetic separator 120 is 2.2T, and the operation time is 1.5 hours. Rinse once, the magnetic medium is rigid mesh, and its material is mainly iron-cobalt alloy. The data before and after the treatment of particulate matter in flue gas are shown in Table 2.

[0064] Table 2 Situation before and after flue gas treatment

[0065] Test items Abbreviation before processing after treatment Removal rate filterable particles FPM 22.67mg / Nm 3

Embodiment example 3

[0067] Such as figure 1 The device shown, process conditions: containing 2.3% magnetic seed spray liquid, the droplet size produced by the nozzle is not greater than 20μm, the field strength of the high gradient magnetic separator 120 is 3.1T, and after 1.2 hours of operation time, the magnetic medium Rinse once, the magnetic medium is bristles, and its material is mainly iron-cobalt alloy. The data before and after the treatment of particulate matter in flue gas are shown in Table 3 below.

[0068] Table 3 Situation before and after flue gas treatment

[0069] Test items Abbreviation before processing after treatment Removal rate filterable particles FPM 18.75mg / Nm 3

3.66mg / Nm 3

80.48% Condensable particulate matter CPM 56.82mg / Nm 3

4.68mg / Nm 3

91.76%

[0070] It can be seen from the processing results of the above three implementation cases that the device 100 and method for removing particulate matter in flue g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com