Cathode active material precursor for secondary battery, preparation method therefor, and method for preparing cathode active material

A positive electrode active material and secondary battery technology, which is applied in the direction of battery electrodes, active material electrodes, positive electrodes, etc., can solve the problems of increased particle surface density, difficulty in uniform sintering, and reduced reactivity, so as to improve capacity and rate performance. Effect of improving cycle characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

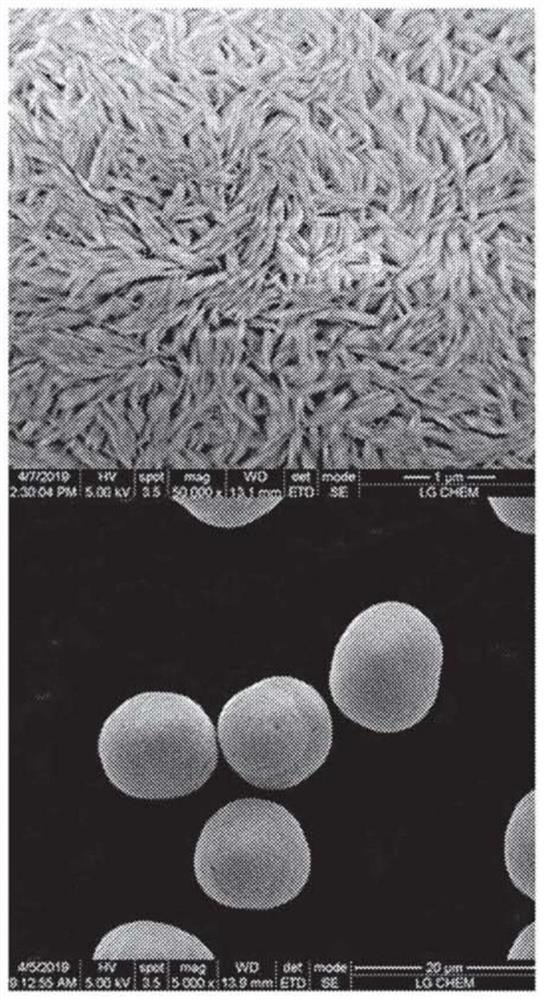

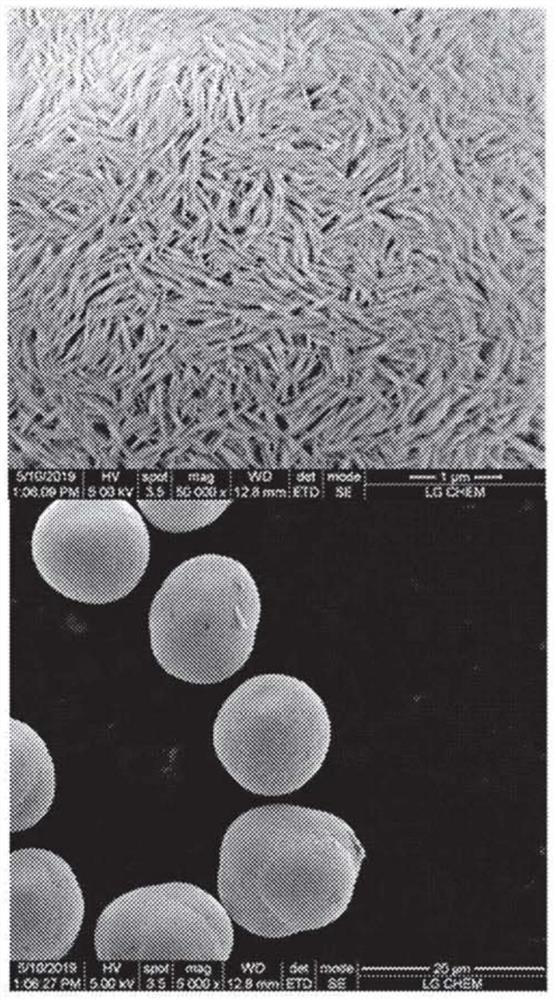

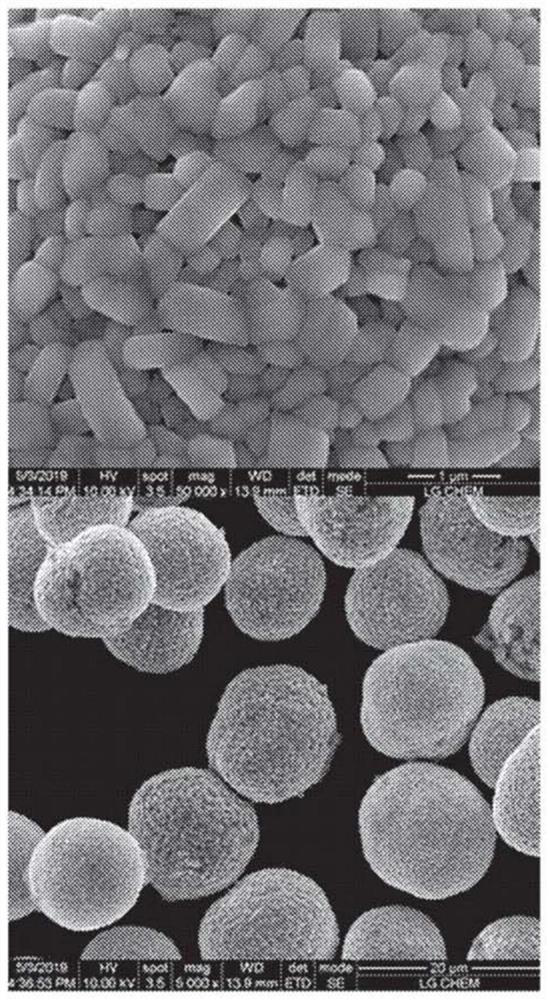

[0031] The invention provides a method for preparing a positive electrode active material precursor for a secondary battery, the method comprising: adding a transition metal-containing solution containing a transition metal cation, an alkaline solution and an ammonium solution to a batch reactor Simultaneously, a cathode active material precursor is prepared by a co-precipitation reaction in which ammonium ions contained in the ammonium solution added to the batch reactor are mixed with transition metal cations contained in the transition metal-containing solution. The molar ratio is below 0.5, and the pH value in the batch reactor is maintained below 11.2.

[0032] The preparation method of the cathode active material precursor will be described in detail for each step.

[0033] First, a cathode active material precursor is prepared through a co-precipitation reaction while adding a transition metal-containing solution containing transition metal cations, an alkaline solution...

Embodiment 1

[0094] After putting 4 liters of distilled water into the batch reactor (capacity 20 L), the temperature was maintained at 60° C., oxygen was supplied at a rate of 3 liters / minute, and stirring was performed at 400 rpm.

[0095] where NiSO 4 、CoSO 4 and MnSO 4 An aqueous transition metal solution having a concentration of 2.28 mol / L mixed in such an amount that the molar ratio of nickel:cobalt:manganese is 92:4:4 was added to the reactor at a rate of 1200 ml / hour, and 15% by weight of ammonia The aqueous solution was continuously added to the reactor at a rate of 108 ml / hour (molar ratio of ammonium ions to total transition metal cations = 0.35). In addition, a 40% by weight aqueous sodium hydroxide solution was added at a rate of 330 ml / hour, and the addition of the aqueous sodium hydroxide solution was adjusted so that the pH was maintained at 11.1.

[0096] Nucleation was performed while stirring at 700 rpm for the first 30 minutes, after which the particles were grown w...

Embodiment 2

[0098] Except that ammonia solution was continuously added to the reactor at a rate of 62 ml / hour (the molar ratio of ammonium ions to total transition metal cations=0.2), the positive electrode active material was prepared in the same manner as in Example 1. body.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com