Friction stir spot welding device and method for operating same

A technology of friction stir and operation method, which is applied in the direction of welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problem of shortening the joining time and achieve the effect of shortening the joining time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

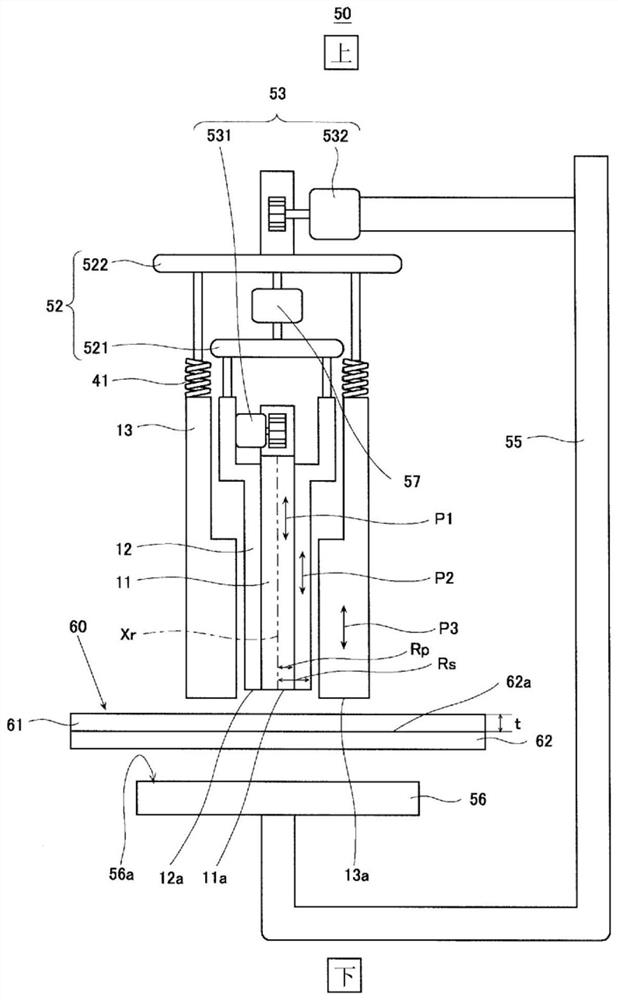

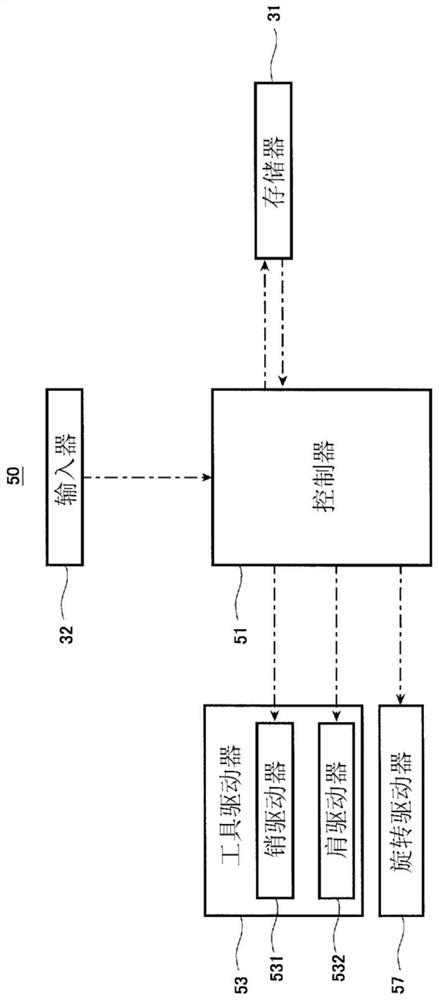

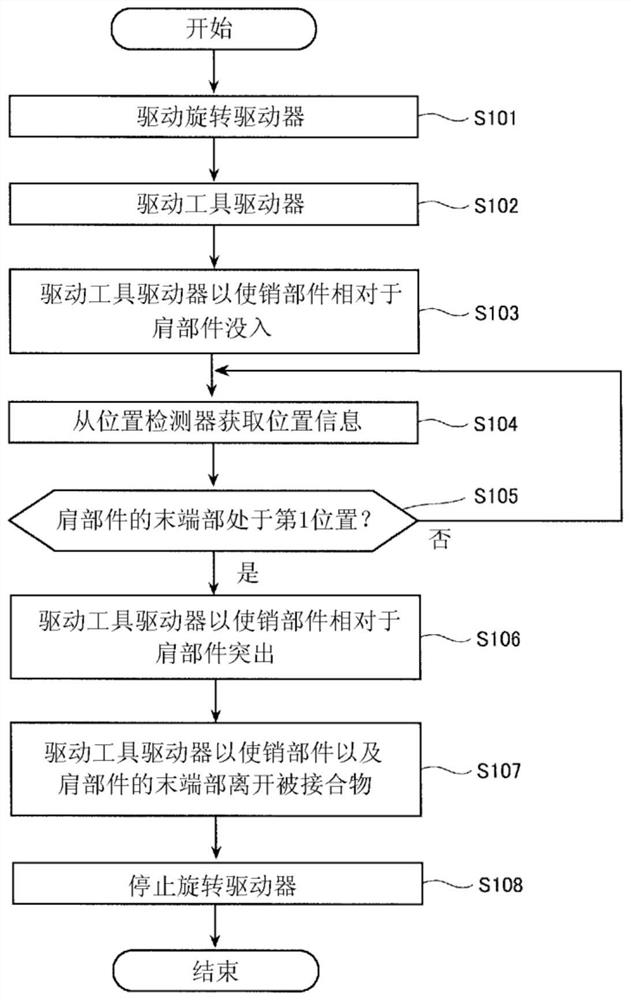

[0030] The friction stir point welding device according to Embodiment 1 is a friction stir point welding device that softens and joins a material to be joined including a first member and a second member by using frictional heat, and the friction stir point welding device includes: a pin member, Formed in a cylindrical shape; a shoulder member, which is formed in a cylindrical shape, and a pin member is inserted inside; a rotary driver, which rotates the pin member and the shoulder member around an axis consistent with the axis of the pin member; an advancing and retreating driver, whose The pin member and the shoulder member are respectively moved forward and backward along the axis; and the controller, the first member is arranged to face the tool and is made of a material with a lower melting point than the second member, and the controller is configured to perform: (A) rotating The driver and the forward and backward driver operate so that the pin member and the shoulder me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com