Integrated force-bearing and flow-equalizing top cover device

An integrated, rectifying device technology, applied in jet propulsion devices, rocket engine devices, machines/engines, etc., can solve the problems of high nozzle mixing ratio, related to thrust chamber combustion efficiency, stability, nozzle ablation, etc., to achieve Avoid structural damage, avoid propellant leakage and structural damage, and reduce the effect of fluid velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

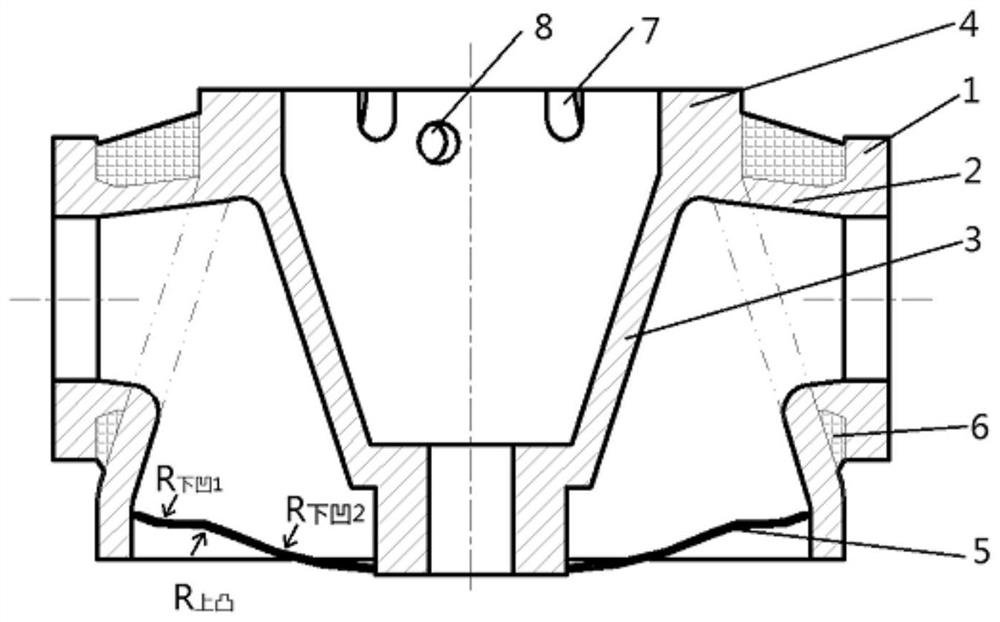

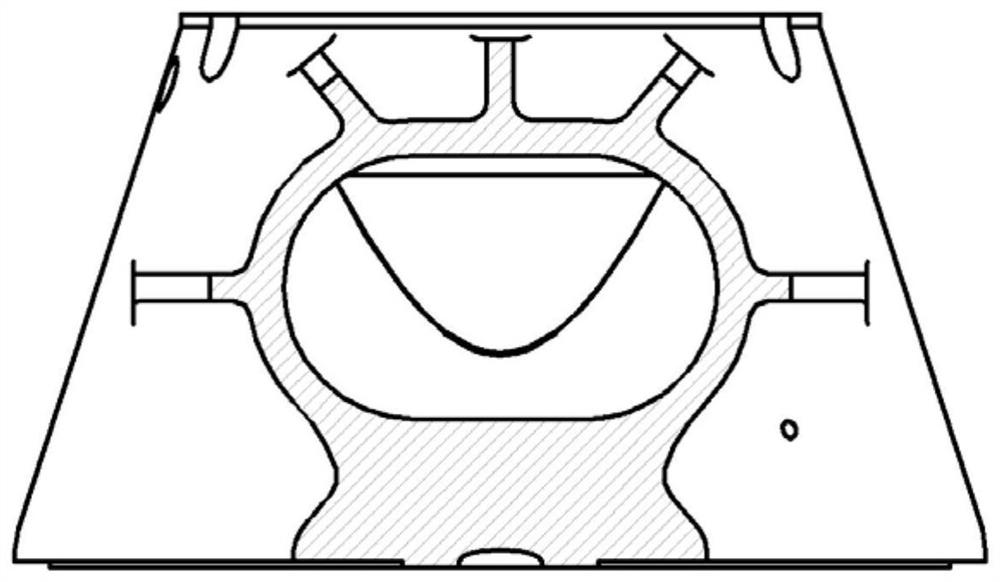

[0028] The present invention proposes an integrated load-bearing and current-equalizing top cover device, such as figure 1 As shown, it includes butt flange 1, inlet section 2, top cover 3, bearing device 4, rectifying device 5 and support rib 6;

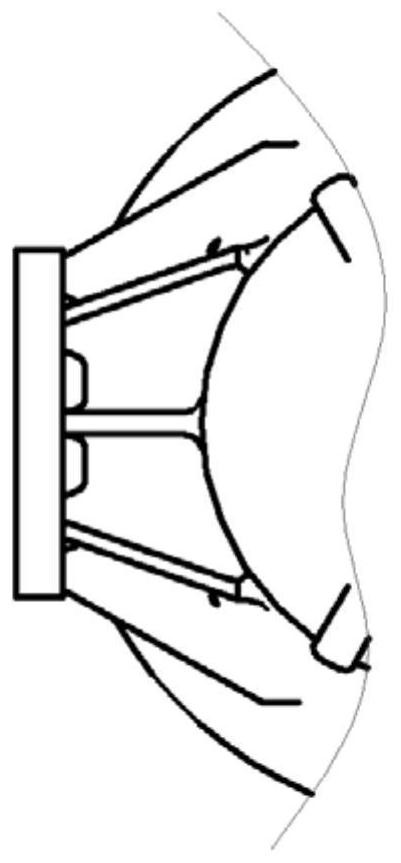

[0029] The port of the docking flange 1 is the propellant inlet, and the docking flange 1 is connected to the top cover 3 through the inlet section 2, and radial support ribs 6 are arranged around the inlet section 2, as shown in figure 2 As shown, the butt flange 1, the inlet section 2 and the top cover 3 are respectively connected; the upper end of the top cover is connected with the bearing device 4 for thrust transmission; the lower end of the top cover 3 is connected with the rectification device 5 for ensuring that the propellant entering each nozzle Evenly distributed. The cross-section of the top cover 3 is double-humped, and the central cavity is a circular platform with a central hole, which is used for connection and in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com