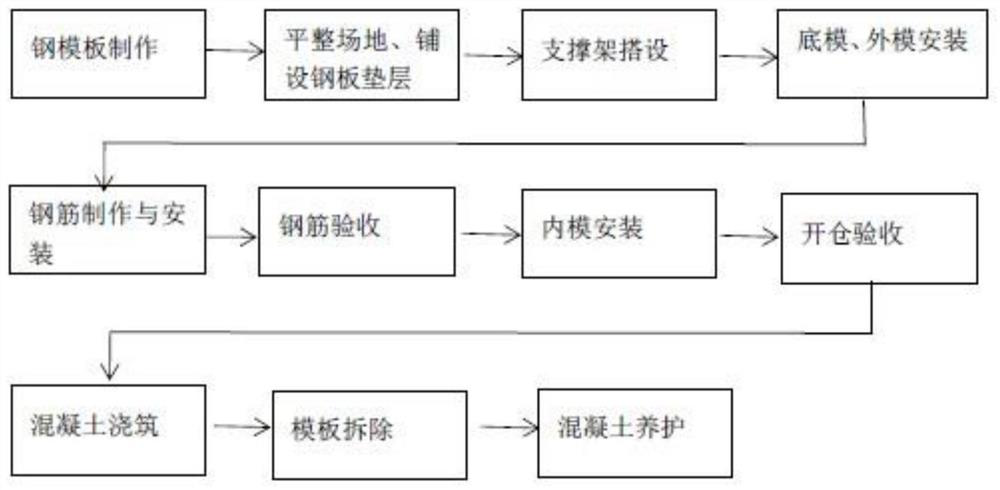

U-shaped aqueduct truss type all-steel formwork construction method

A construction method and steel formwork technology, applied in water conservancy projects, artificial waterways, infrastructure engineering, etc., can solve the problems of aqueduct wall structure damage, affecting the normal use of aqueducts, corrosion of steel bars, etc., to reduce installation and dismantling costs, Fast inspection and acceptance, and the effect of safe construction guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

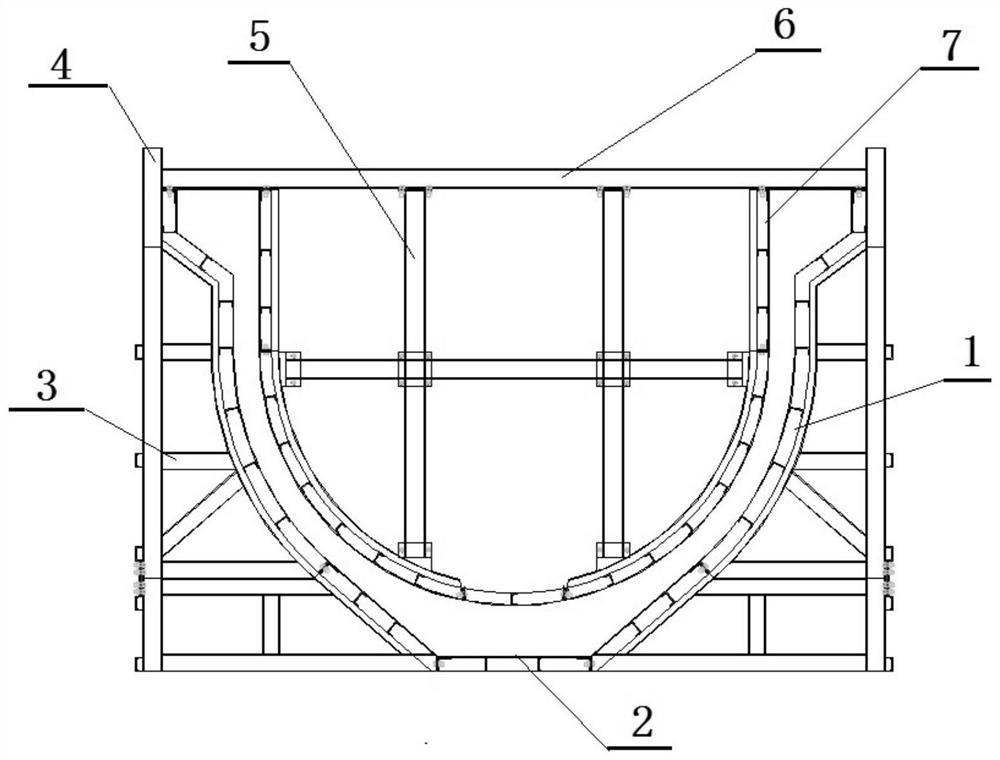

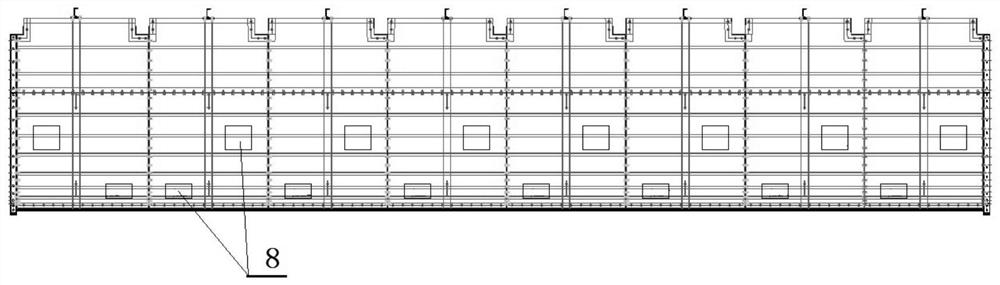

[0031] as attached figure 2 , attached image 3 As shown, the U-shaped aqueduct truss-type all-steel formwork construction method of the present invention is an example of a water conservancy project aqueduct project in Guangxi. The template used in the construction method includes a steel base plate, a support frame, an outer formwork 1, a base form 2 and an inner formwork 7; Mold 2, bottom mold 2 is located in the middle of the bottom of the entire aqueduct, and is used to connect the outer mold 1 that is arranged symmetrically on both sides. The inner surface of the outer mold 1 is arc-shaped to fit the U-shaped aqueduct, and the outer surface is vertical. Column, the support column is horizontally arranged to support the horizontal column B3 of the inner side of the outer mold, and the column B4 perpendicular to the horizontal column B is set; the inner mold 7 is located above the outer mold, and the inner mold 7 is a U-shaped structure. The bottom of the inner mold 7 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com