Antibacterial and deodorant functional fabric and production process thereof

A technology with anti-odor function and production process, which is applied in the field of fabric manufacturing, can solve the problems of affecting drying and easy retention of fabrics, etc., and achieve the effect of easy reset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

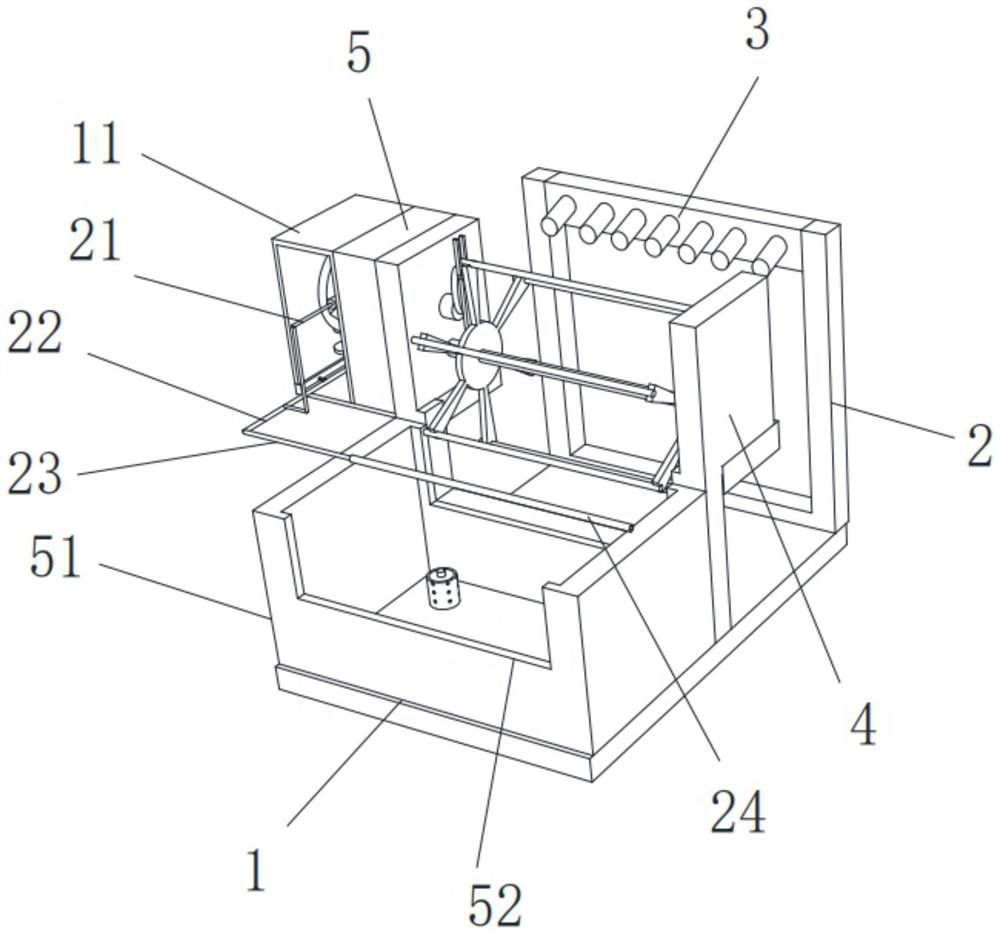

[0043] Example 1: See figure 1 , Figure 7 , Figure 8 and Figure 9 , an antibacterial and deodorant finishing device, comprising a base plate 1, two groups of side plates 4 are fixedly installed on the base plate 1, a shaking mechanism for vibrating cloth is arranged on the side wall of the side plate 4, the shaking mechanism includes a biaxial motor 5, The biaxial motor 5 is fixedly mounted on the side wall of the side plate 4, the biaxial motor 5 is provided with a motor shaft 12, and the motor shaft 12 is movably mounted on the side plate 4, and the side wall of the biaxial motor 5 is fixedly installed with Rectangular placement frame 11, the motor rotating shaft 12 runs through the rectangular placement frame 11 and moves in the rectangular placement frame 11, and the outside of the rectangular placement frame 11 is fixedly equipped with a first runner 13 and a second runner 14, and the semicircular groove 15 is arranged on Fit the end of one side of the biaxial moto...

Embodiment 2

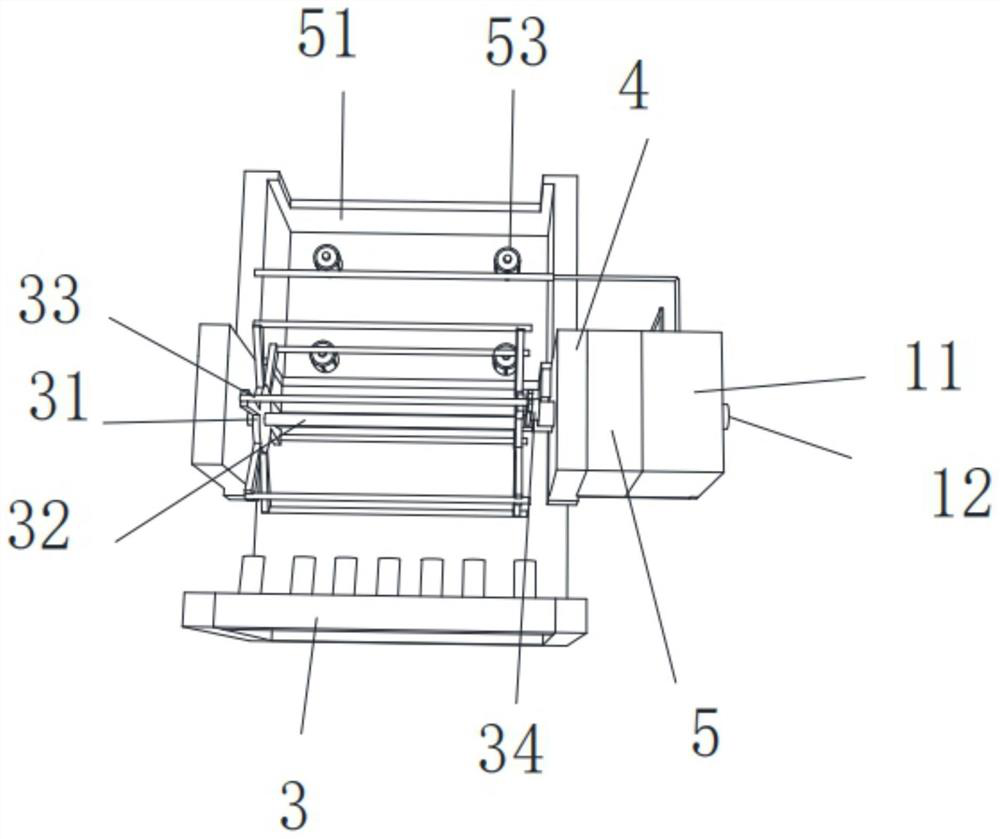

[0046] Example 2: see figure 1 , Figure 4 and 10 , on the basis of Embodiment 1, the top of the base plate 1 is provided with a processing mechanism for soaping the fabric, the processing mechanism includes a soaping pool 51, and the soaping pool 51 is fixedly installed on the upper surface of the base plate 1, and the soaping pool 51 A rectangular groove 52 is provided, and a storage tank 53 is fixedly installed on the bottom surface of the inner side wall of the soaping pool 51. The storage tank 53 is provided with equidistant and evenly arranged circular holes 55, and an extruding plate 54 is movably installed in the storage tank 53.

[0047] When in use, move the extruding plate 54 to take out the extruding plate 54 from the storage tank 53, then put the soap into the storage tank 53, cover the extruding plate 54, and the soap passes through the circular hole 55 and water Contact to realize the release of soapy water. When soaping the fabric, the soap will not come int...

Embodiment 3

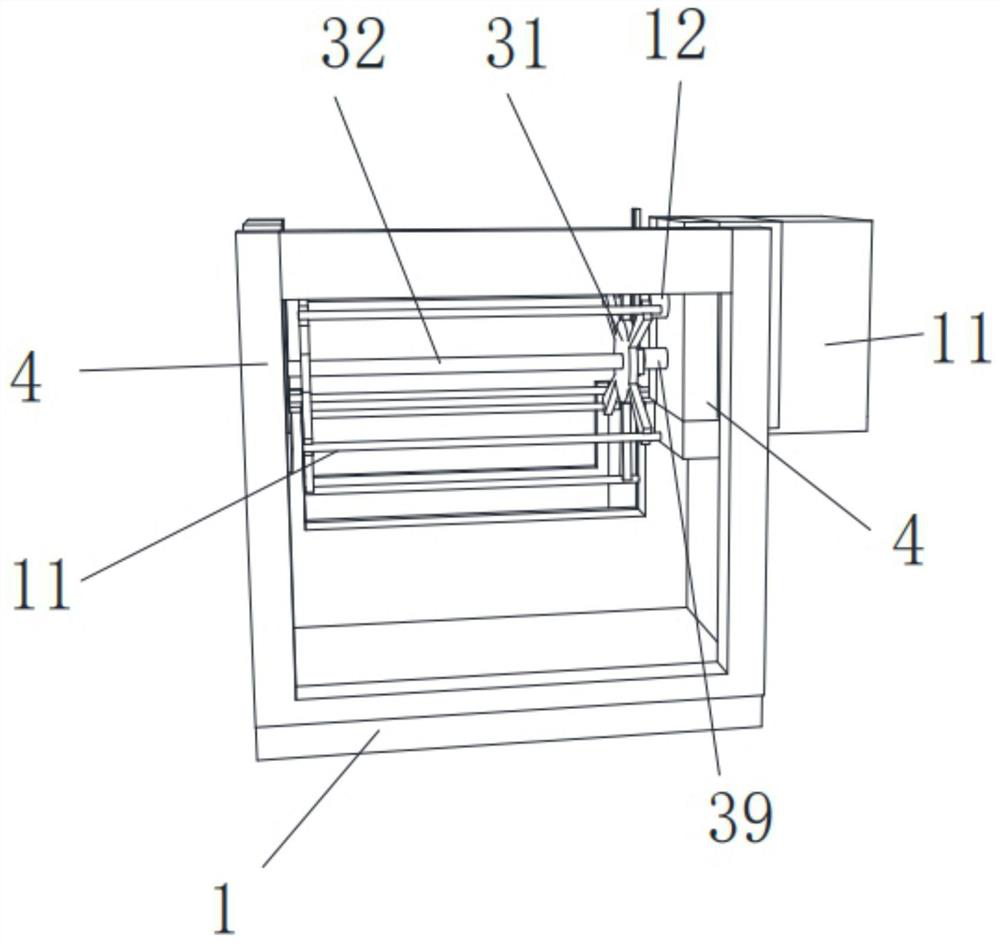

[0048] Example 3: See figure 2 , image 3 , Figure 5 and Figure 6 , on the basis of Embodiment 1, a transmission mechanism for transporting fabrics is provided between the side plates 4. The transmission mechanism includes a transmission moving block 34, and a connecting rotating shaft 35 is fixedly installed on the transmitting moving block 34. The connecting rotating shaft 35 and the motor rotating shaft 12 are fixedly installed together, and a U-shaped block 36 is also movably installed on the transmission moving block 34, and a rectangular insert block 37 is fixedly installed below the U-shaped block 36, and a U-shaped groove 41 is provided on the U-shaped block 36, and the side plate 4 A circular cylinder 39 is fixedly installed on the side wall, and the circular cylinder 39 is arranged below the motor shaft 12. A rectangular sleeve 38 is movably installed on the circular cylinder 39, and a rectangular insert 37 is movably installed on the rectangular sleeve. In 38, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com