Compound dual-modified asphalt mixture additive and preparation method thereof

A technology of modified asphalt and mixture, which is applied in building insulation materials, building components, buildings, etc. It can solve the problems of asphalt pavement high temperature stability and low rutting ability, complex modification process, and pollute the environment, so as to improve high temperature stability Excellent properties and low-temperature crack resistance, increased viscoelastic range, and anti-agglomeration effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A compound double-modified asphalt mixture additive, made of the following raw materials in weight percentage: rock asphalt 60%, chitosan 30%, silicon mineral powder 5%, gelatin 4.7%, mannitol 0.3%, the silicon Mineral powder is nano-scale and contains 97% silicon dioxide.

[0025] The preparation method of the compound double-modified asphalt mixture additive described above comprises the following steps:

[0026] (1) Carrying out ultrafine pulverization of rock asphalt for 13 minutes to obtain rock asphalt micropowder;

[0027] (2) dissolving the gelatin in water at 80°C that is 100 times its weight, and after the gelatin is dissolved, add mannitol and stir evenly to obtain a mixed solution;

[0028] (3) The mixed liquid is processed by high-pressure micro-jet, the conditions of high-pressure micro-jet: the pressure is 55MPa, the temperature is 70°C, and the time is 22min, to obtain the second mixed liquid;

[0029] (4) Spray the second mixed solution on the surface...

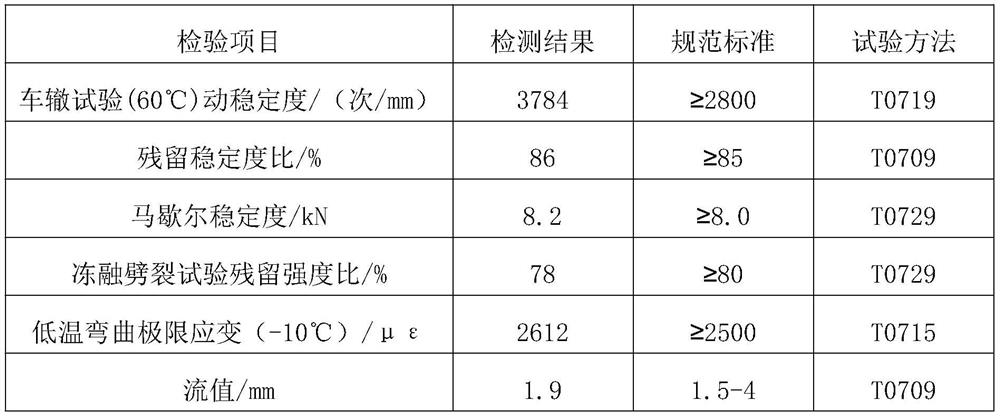

Embodiment 2

[0034] A compound double-modified asphalt mixture additive, made of the following raw materials in percentage by weight: rock asphalt 80%, chitin 6%, silica mineral powder 10%, gelatin 3%, mannitol 1.0%, the silica mineral The powder is nanoscale and contains 97% silicon dioxide.

[0035] The preparation method of the compound double-modified asphalt mixture additive described above comprises the following steps:

[0036] (1) Carrying out ultrafine pulverization of rock asphalt for 14 minutes to obtain rock asphalt micropowder;

[0037] (2) dissolving the gelatin in water at 70°C that is 80 times its weight, and after the gelatin is dissolved, add mannitol and stir evenly to obtain a mixed solution;

[0038] (3) The mixed solution is processed by high-pressure micro-jet, the conditions of high-pressure micro-jet: the pressure is 60MPa, the temperature is 66°C, and the time is 24min, to obtain the second mixed solution;

[0039] (4) Spray the second mixed solution on the surf...

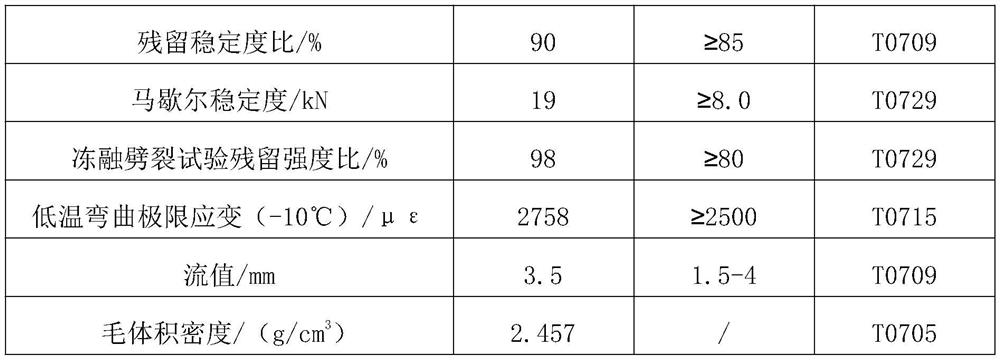

Embodiment 3

[0043] A compound double-modified asphalt mixture additive, made of the following raw materials in weight percentage: rock asphalt 70%, alginic acid 16.5%, silica ore powder 7%, gelatin 6%, mannitol 0.5%, the silica ore The powder is nanoscale and contains 97% silicon dioxide.

[0044] The preparation method of the compound double-modified asphalt mixture additive described above comprises the following steps:

[0045] (1) Carry out rock asphalt ultrafine pulverization 16min, obtain rock asphalt micropowder;

[0046] (2) dissolving the gelatin in water at 65°C that is 85 times its weight, and after the gelatin is dissolved, add mannitol and stir evenly to obtain a mixed solution;

[0047] (3) The mixed solution is processed by high-pressure micro-jet, the conditions of high-pressure micro-jet: the pressure is 70MPa, the temperature is 62°C, and the time is 26min, to obtain the second mixed solution;

[0048] (4) Spray the second mixed solution on the surface of rock asphalt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com