Method for synthesizing 3-ethylamino-4-methylphenol

A methylphenol, ethylamine-based technology, applied in the field of organic synthesis, can solve problems such as difficult recycling, large safety hazards, and increased difficulty, achieve real-time online detection and analysis, save equipment space, and improve process The effect of R&D efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

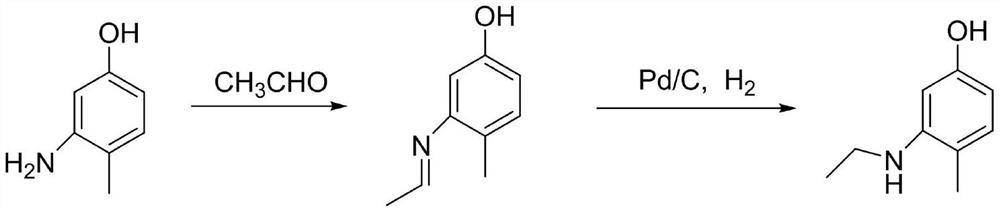

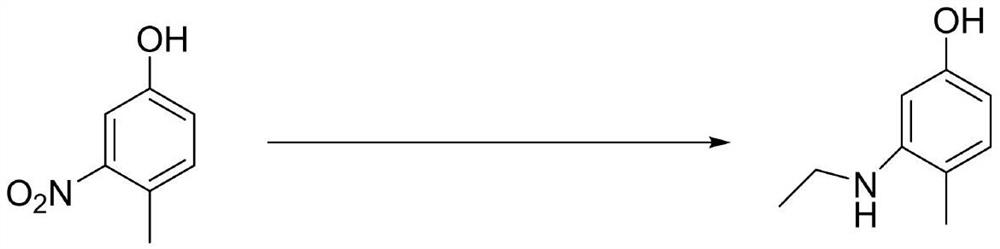

Method used

Image

Examples

Embodiment 1

[0028] Take by weighing 153g 3-nitro-4-methylphenol and 2.55g B (C6F5) 3 be dissolved in 1L tetrahydrofuran and ethanol 1:1 (volume ratio, the following examples are all the same) in the mixed solvent, stir until dissolving clear, then Inject it into the preheating module and preheat it to 10°C; set the palladium carbon loading to 2mL, the particle size to 0.2mm, and the pressure to 5atm, then control the H2 feed flow rate to 20sccm; N2 feed flow rate to 60sccm, Finally, inject the preheated 3-nitro-4-methylphenol solution into the preheated reaction module at a feed flow rate of 0.5 mL / min. Collect the effluent reaction solution (sampling HPLC analysis, raw material 3.3%, main impurity (diethylation) 13.7%, product 82.6%), spin the solvent, and use 350mL petroleum ether / 20mL methyl tert-butyl ether (the ratio of the following examples (all the same) beating for 1 hour, suction filtered to obtain a white solid, and dried to obtain 91 g of product with a yield of 60%, HPLC: 95....

Embodiment 2

[0030] Weigh 153g of 3-nitro-4-methylphenol and 2.55g of B(C6F5)3 and dissolve in 1L of tetrahydrofuran and ethanol 2:1 mixed solvent, stir until dissolved, then inject it into the preheating module and preheat to 25°C; set the loading amount of palladium carbon to 3mL, the particle size to 0.3mm, and the pressure to 5atm, then control the feed flow rate of H2 to 30sccm; the feed flow rate of N2 to 60sccm, and finally preheat the 3-nitro- The 4-methylphenol solution was injected into the preheated reaction module at a feed flow rate of 0.75mL / min. Collect the effluent reaction solution (sample HPLC analysis, raw material 1.1%, main impurity (diethylated) 8.8%, product 89.9%), spin to dry the solvent, beat with petroleum ether / methyl tert-butyl ether mixed solvent for 1h, and suction filter A white solid was obtained, and 108 g of product was obtained by drying, with a yield of 72%, GC / HPLC: 96.5%.

Embodiment 3

[0032] Weigh 153g of 3-nitro-4-methylphenol and 2.55g of B(C6F5)3 and dissolve in 1L of tetrahydrofuran and ethanol 2:1 mixed solvent, stir until dissolved, then inject it into the preheating module and preheat to 40°C; set the loading amount of palladium carbon to 4mL, the particle size to 0.4mm, and the pressure to 5atm, then control the feed flow rate of H2 to 20sccm; the feed flow rate of N2 to 60sccm, and finally preheat the 3-nitro- The 4-methylphenol solution was injected into the preheated reaction module at a feed flow rate of 0.75mL / min. Collect the effluent reaction solution (sample HPLC analysis, raw material 4.9%, main impurity (diethylated) 10.3%, product 84.5%), spin to dry the solvent, beat with petroleum ether / methyl tert-butyl ether mixed solvent for 1h, and suction filter A white solid was obtained, and 110 g of the product was obtained by drying, with a yield of 73%, HPLC: 94.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com