Method for recycling waste liquid from butanol device

A waste liquid and butanol technology, applied in chemical instruments and methods, preparation of organic compounds, separation/purification of hydroxyl compounds, etc., can solve the problem of inability to ensure long-term stable operation of the device, unfavorable recovery of valuable components, and use of catalysts Short service life and other problems, to achieve the effect of ensuring long-term stable operation, realizing gas phase recycling, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

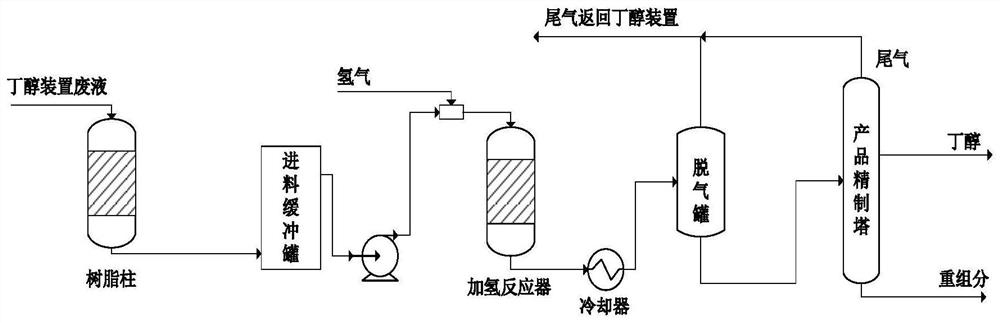

Method used

Image

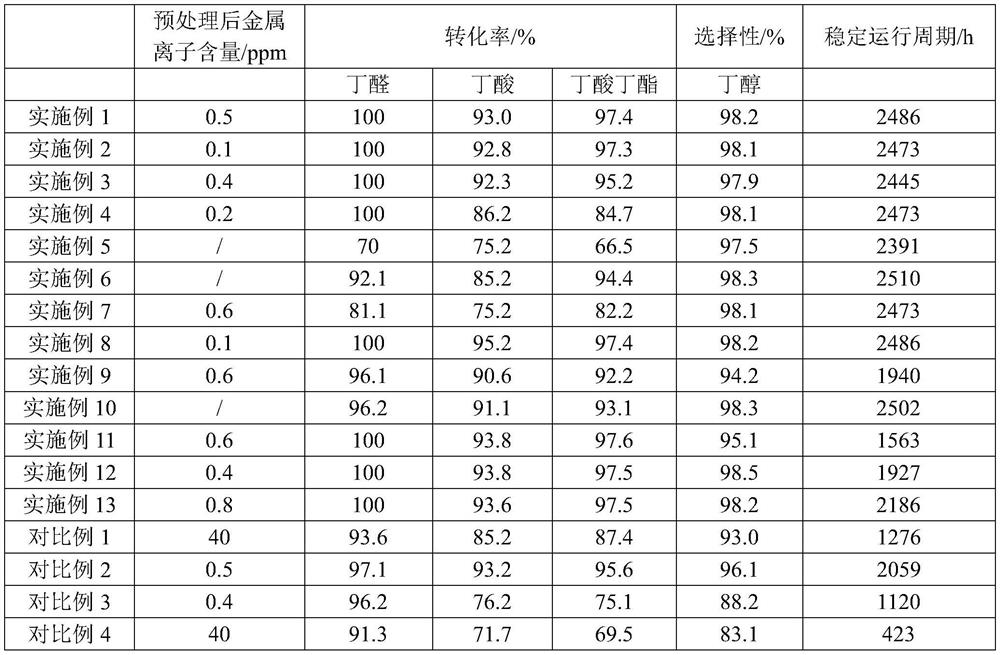

Examples

Embodiment 1

[0045] [Preparation Example 1] Preparation of Catalyst A

[0046] Add 3kg of deionized water into the reaction kettle, add 11.7g of nano-titanium dioxide with a particle size of 20-30nm, and stir evenly.

[0047] Dissolve 270.2g of anhydrous copper nitrate, 631.2g of aluminum nitrate nonahydrate, and 65.8g of zinc nitrate hexahydrate in 2.5kg of deionized water to form a mixed metal solution; prepare a sufficient amount of 20% sodium carbonate solution in addition; and sodium carbonate solution were heated to 80°C, and were added dropwise to the reactor for co-precipitation reaction. The temperature of the reactor was controlled at 80°C to keep the temperature constant. 6. After 1.5h, the metal mixed solution was added dropwise. Adjust the pH of the system to 9 with the above sodium carbonate solution, and age for 3 hours.

[0048] Then filter, wash and dry the filter cake at 120°C for 24h, and roast at 600°C for 5h, break the roasted filter cake into strips, and cut strips ...

Embodiment 2

[0049] [Preparation Example 2] Preparation of Catalyst B

[0050] Add 3kg of deionized water into the reaction kettle, add 11.7g of nano-titanium dioxide with a particle size of 20-30nm, and stir evenly.

[0051] Dissolve 272.8g of anhydrous copper nitrate, 630.5g of aluminum nitrate nonahydrate, and 133.1g of zinc nitrate hexahydrate in 2.5kg of deionized water to form a mixed metal solution. In addition, a sufficient amount of 20wt% sodium carbonate solution is prepared; both the metal mixed solution and the sodium carbonate solution are heated to 80°C, and are simultaneously added dropwise to the reactor for coprecipitation reaction, and the temperature of the reactor is controlled at 80°C. The dropwise amount of sodium carbonate solution is to maintain the pH of the system at 5-6, and the dropwise addition of the mixed solution is completed within 1.5 hours. Adjust the pH of the system to 9 with the above sodium carbonate solution, and age for 3 hours.

[0052] Then filt...

Embodiment 3

[0053] [Preparation Example 3] Preparation of Catalyst C

[0054] Add 3kg of deionized water into the reaction kettle, add 11.7g of nano-titanium dioxide with a particle size of 20-30nm, and stir evenly.

[0055] 408.6g of anhydrous copper nitrate, 629.6g of aluminum nitrate nonahydrate, and 66.3g of zinc nitrate hexahydrate were dissolved in 2.5kg of deionized water to form a metal mixed solution; in addition, a sufficient amount of 20wt% sodium carbonate solution was prepared, and the metal mixed solution and sodium carbonate solution are heated to 80°C, and are added dropwise into the reactor for co-precipitation reaction. After 1.5h, the dropwise addition of the mixed solution was completed. Adjust the pH of the system to 9 with the above sodium carbonate solution, and age for 3 hours.

[0056] Then filter, wash and dry the filter cake at 120°C for 24 hours, then roast it at 600°C for 5 hours, break the roasted filter cake into strips, and cut them into strip catalysts w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com