Production process suitable for large-size earthenware pipe product

A production process and large-scale technology, applied in the field of building curtain walls, can solve problems such as poor circulation of hot air, low safety factor, and rapid surface shrinkage, and achieve the effects of reducing bending stress and deformation deflection, solving technical bottlenecks, and uniform shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1 of the present invention provides a production process suitable for large-scale pottery pipe products.

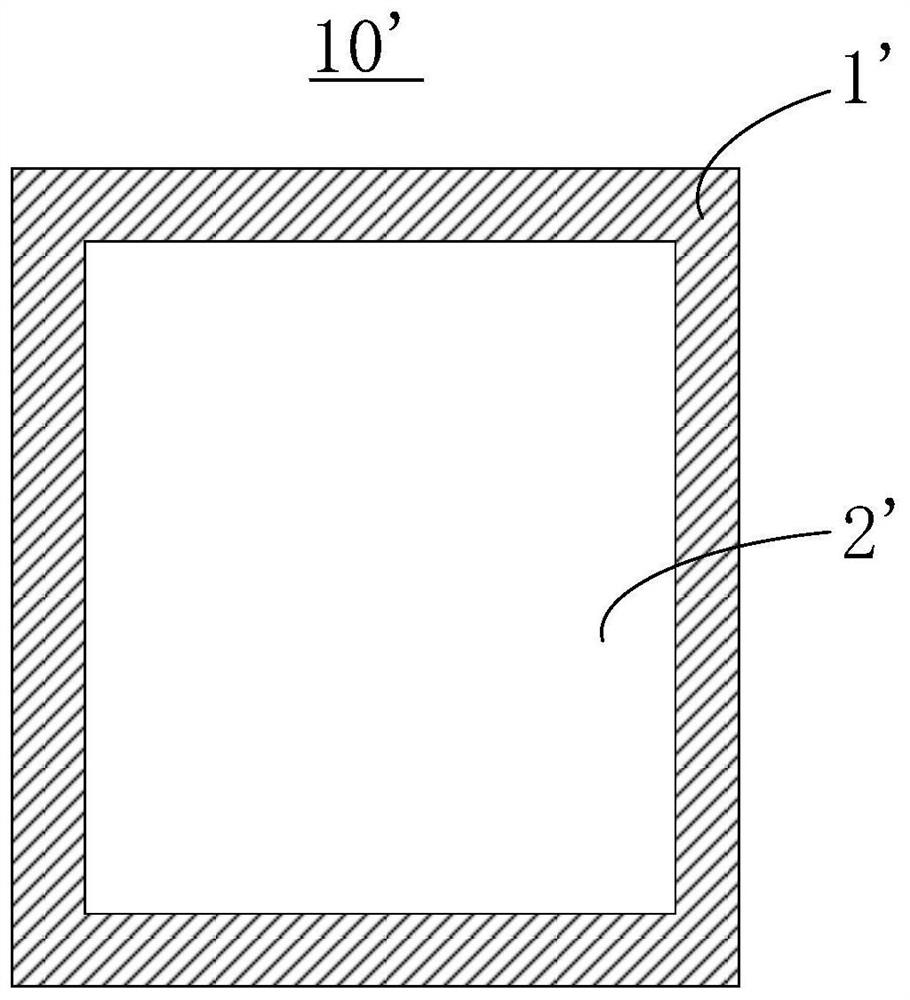

[0048] The large-scale pottery tube product produced in Example 1 of the present invention has a schematic diagram of the overall structure as Figure 4 As shown, it has a tubular structure with both ends open, and has a hollow cavity 2 extending in the axial direction inside. The ceramic tube 10 includes a wall thickness portion 1 surrounding the hollow cavity 2 .

[0049] Regarding the wall thickness part 1 , it is also called the tube wall part, that is, the part that forms the wall thickness of the pottery tube around the hollow cavity 2 as a whole.

[0050]Specifically, in this embodiment, the tubular structure of the pottery tube 10 is a rectangular tubular structure, and the hollow cavity 2 is also a rectangular column.

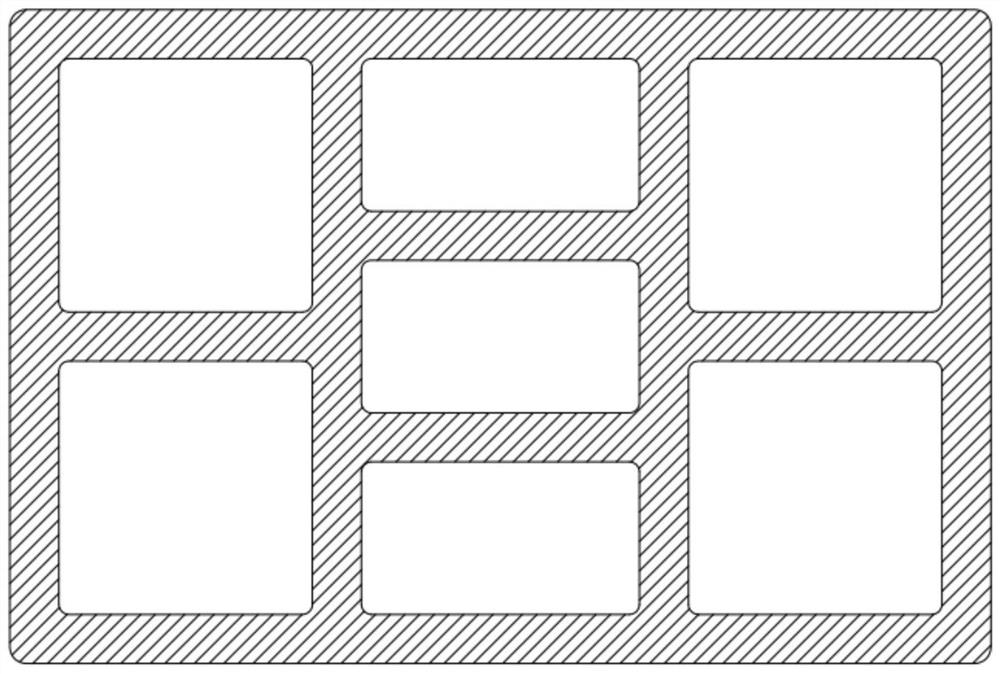

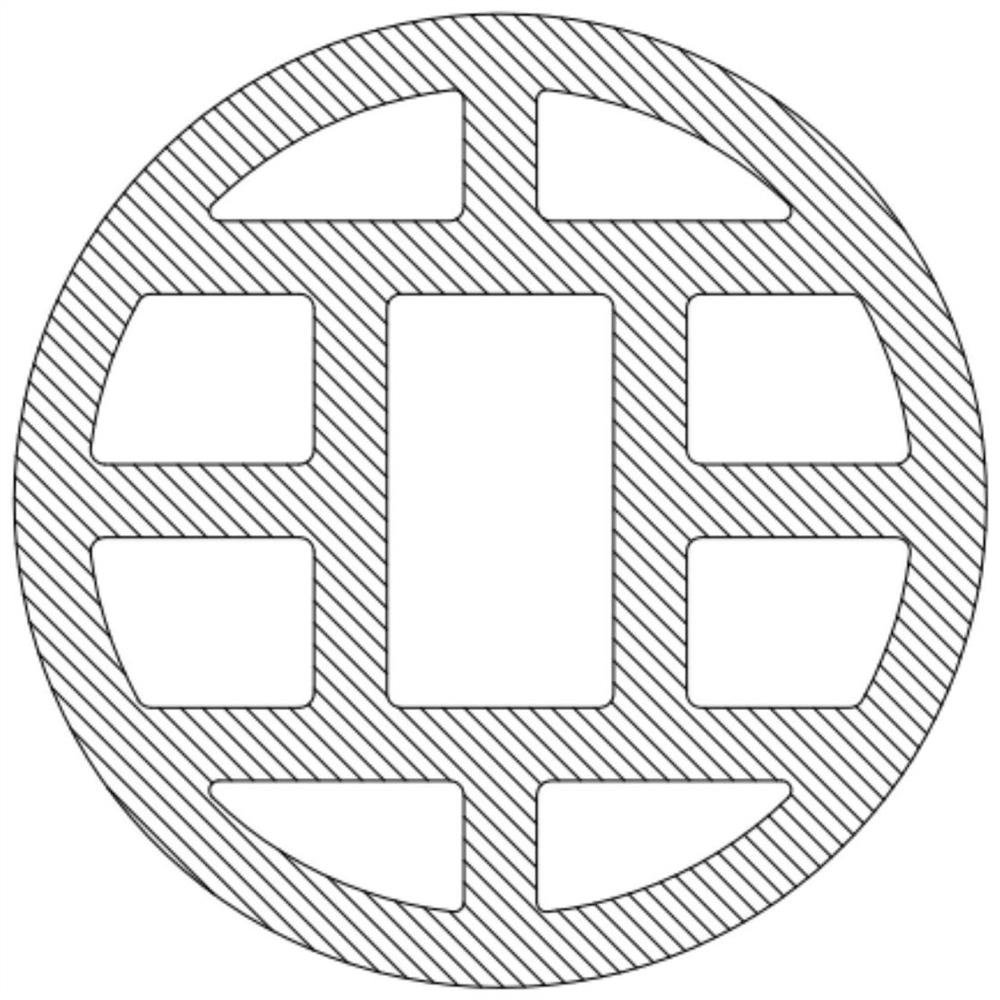

[0051] Such as Figure 5 As shown in the cross-sectional view of the pottery tube 10 , several through holes 3 extending in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com