Preparation method of wind power blade

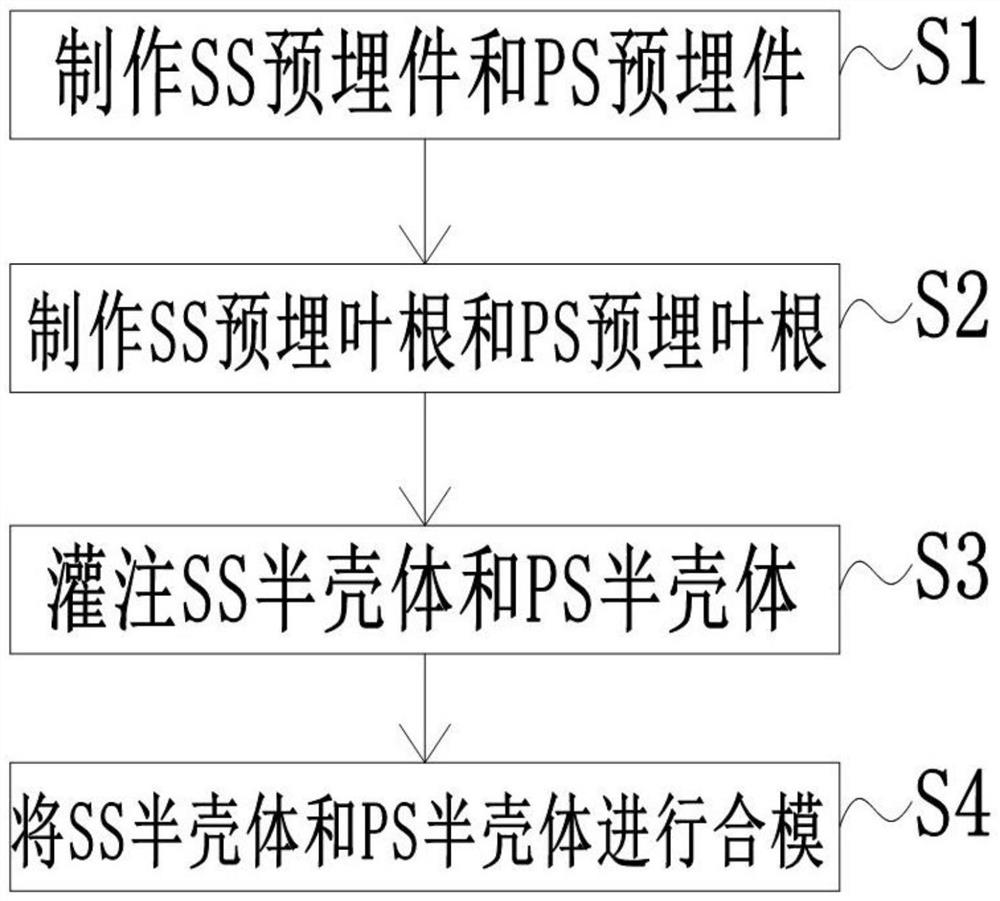

A wind power blade and root method technology, applied in wind power generation, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as installation interference, large deformation, misalignment of screw sleeve holes and main engine bearing connection holes, etc., to achieve blade The effect of reduced root deformation and high counterboring precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The following is further described in detail through specific implementation methods:

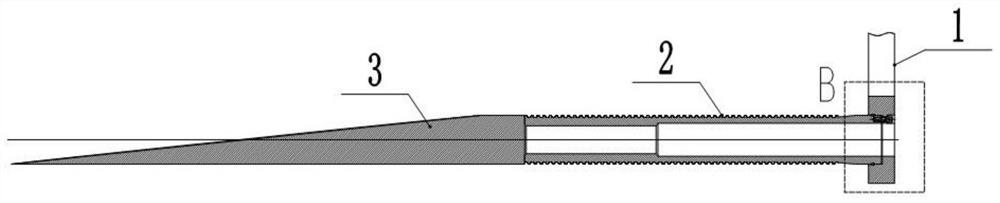

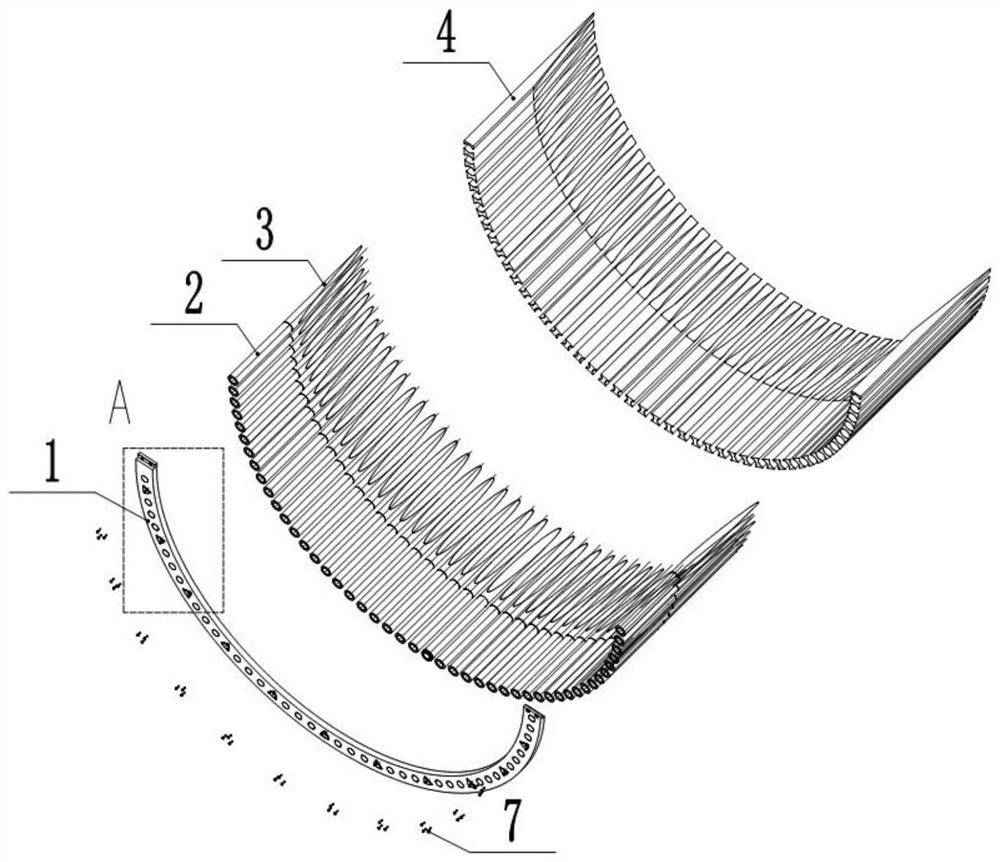

[0050] The reference signs in the drawings of the specification include: connecting flange 1, screw sleeve 2, wedge block 3, UD block 4, L-shaped groove 5, connecting hole 6, countersunk bolt 7, second counterbore 8, connecting flange Mounting hole 9, sealing ring 10, SS embedded parts 11, SS surface embedded blade root mold 12, embedded blade root flange 13, lock buckle 14, embedded blade root bolts 15, PS surface embedded blade root mold 16. Press block 17, first positioning block 18, first positioning groove 19, lock groove 20, first threaded hole 21, second positioning groove 22, second positioning block 23, SS shell mold 24, SS embedded leaf Root 25, blade upper mold 26, blade lower mold 27, upper steel frame 28, lower steel frame 29, first positioning component 30, support component 31, grasping component 32, first axial positioning block 33, second axial positioning Block 34,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com