Welding device and method for electronic component

A technology of electronic components and welding devices, which is applied in the direction of assembling printed circuits, auxiliary devices, welding equipment, etc. of electrical components, which can solve problems such as low welding efficiency, solder cracks, and prone to stress tendency, so as to improve welding efficiency and prevent cracks , the effect of less prone to stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

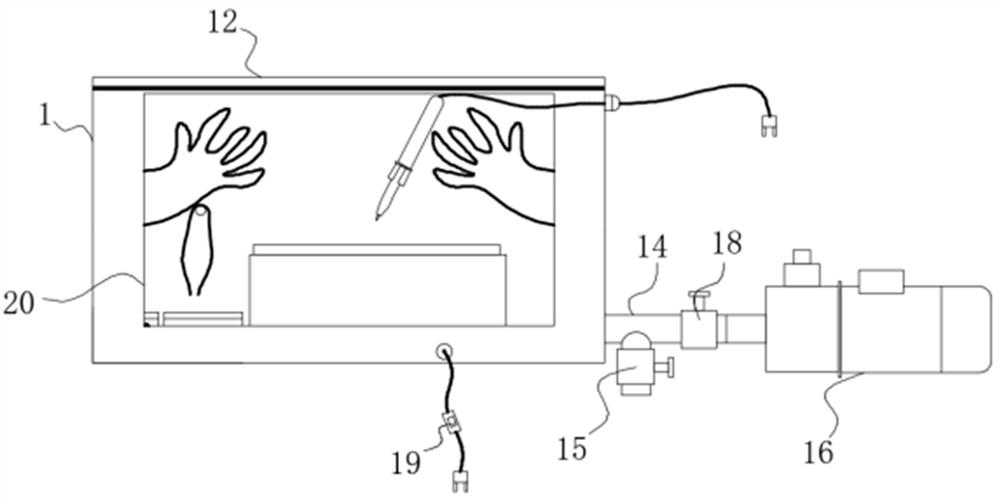

[0041] Please refer to figure 1 and figure 2 , the embodiment of the present invention provides a welding device for electronic components, including a vacuum pump 16 and a sealed welding operation box 1 that can observe all the scenes inside from the outside. The top of the welding operation box 1 is provided with a sealing cover 12;

[0042] The welding operation box 1 is communicated with the first end of a three-way pipe 14, the second end of the three-way pipe 14 is provided with the first on-off gas valve 15, and the third end is provided with the second on-off gas valve 18 and is connected with the vacuum pump 16. suction port connection;

[0043] Soldering operation box 1 is provided with electric soldering iron 9, electronic component placement box 4, solder placement box 3, tweezers 10, silicone glove Ⅰ 8, silicone glove Ⅱ 7 and PCB placement seat 2, PCB placement seat 2 has a built-in infrared heater 17, The power plug of the infrared heater 17 and the power plug...

Embodiment 2

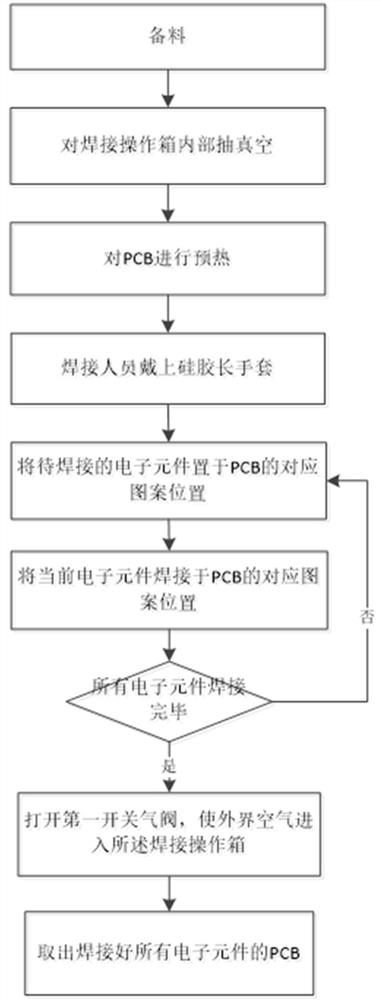

[0052] Please refer to figure 1 , figure 2 and image 3 , the embodiment of the present invention provides an electronic component welding method based on the welding device described in embodiment 1, specifically comprising the following steps:

[0053] S1. Open the sealing cover 12, place the required solder in the solder placement box 3, place the electronic components to be soldered in the electronic component placement box 4, place the PCB to be soldered on the PCB placement seat 2, and then cover Upper sealing cover 12;

[0054] S2, open the second switching gas valve 18, close the first switching gas valve 15, utilize the vacuum pump 16 to vacuumize the inside of the welding operation box 1, and then close the second switching gas valve 18;

[0055] S3. Connect the electric soldering iron 9 and the infrared heater 17 to the power supply, and preheat the PCB through the infrared heater 17. After reaching 120~130°C, cut off the power supply of the infrared heater 17, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com