Household garbage clean gasification power generation method and device

A domestic waste and waste-to-energy technology, which is applied in fixed bed gasification, chemical industry, and the manufacture of combustible gas, etc., can solve the problems of limited gas volume and inapplicability to complex types of domestic waste, so as to save energy and improve energy conversion Efficiency, the effect of simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

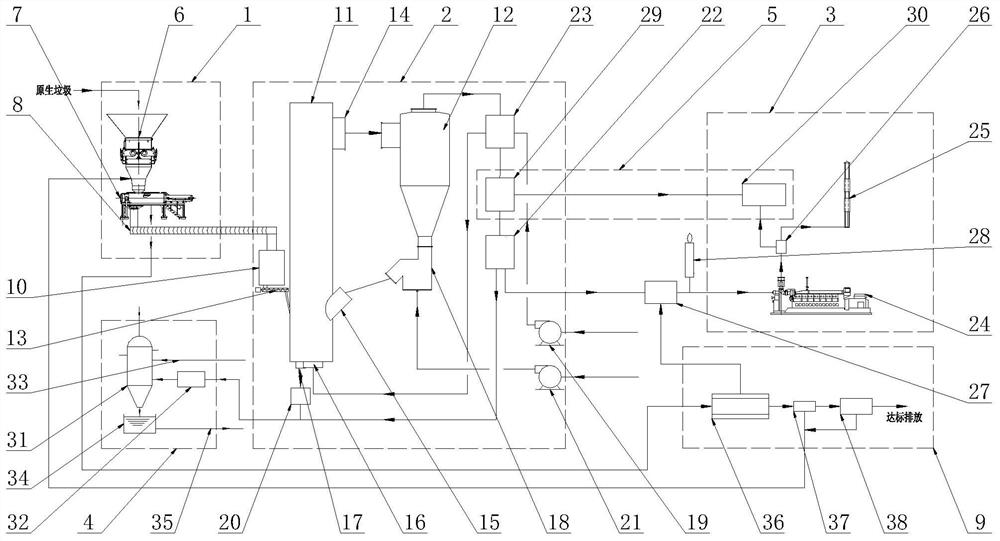

[0046] Embodiment 1 of the present invention: a method for generating electricity by clean gasification of domestic waste, comprising the following steps:

[0047] S1, Garbage pretreatment: transport the raw garbage to the garbage pretreatment system 1, and separate the raw garbage into dry garbage and wet garbage;

[0048] S2, garbage gasification: the separated dry garbage is transported to the garbage gasification system 2 for gasification treatment, and the dry garbage is gasified to produce synthesis gas and ash;

[0049] S3, waste-to-energy: the gasification synthesis gas is transported to the waste-to-energy system 3 for power generation;

[0050] S4, ash melting: the ash generated after garbage gasification is transported to the ash melting system 4 for ash treatment.

Embodiment 2

[0051] Embodiment 2 of the present invention: a method for generating electricity by clean gasification of domestic waste, comprising the following steps:

[0052] S1, Garbage pretreatment: transport the raw garbage to the garbage pretreatment system 1, and separate the raw garbage into dry garbage and wet garbage;

[0053] S2, garbage gasification: the separated dry garbage is transported to the garbage gasification system 2 for gasification treatment, and the dry garbage is gasified to produce synthesis gas and ash;

[0054] S3, waste-to-energy: the gasification synthesis gas is transported to the waste-to-energy system 3 for power generation;

[0055] S4, ash melting: the ash generated after garbage gasification is transported to the ash melting system 4 for ash treatment;

[0056] S5, low-temperature waste heat power generation: the synthetic gas produced by the waste gasification system 2 and the water vapor generated by the cooling of the high-temperature flue gas produ...

Embodiment 3

[0058] Embodiment 3 of the present invention: a method for generating electricity by clean gasification of domestic waste, comprising the following steps:

[0059] S1, Garbage pretreatment: transport the raw garbage to the garbage pretreatment system 1, separate the raw garbage into dry garbage and wet garbage; transport the raw garbage to the crusher 6 for crushing, and send the crushed raw garbage to the dry and wet separation Machine 7 performs dry-wet separation, and separates raw garbage into dry garbage and wet garbage. The dry garbage is transported to the garbage gasification system 2 through the transportation device 8 for gasification treatment, and the wet garbage enters the wet garbage anaerobic treatment system 9 through the pipeline for treatment. Anaerobic fermentation treatment;

[0060] S2, garbage gasification: the separated dry garbage is transported to the garbage gasification system 2 for gasification treatment, and the dry garbage is gasified to produce s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com