Formula and preparation method of electronic cigarette tobacco tar

An electronic cigarette and formula technology, applied in the direction of tobacco, tobacco processing, application, etc., can solve problems such as practical application limitations, and achieve the effect of improving the sweetness and greasy feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

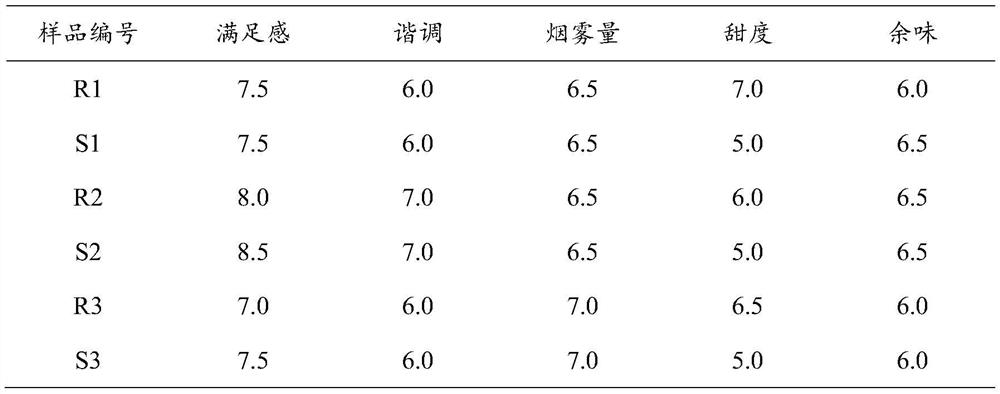

Examples

preparation example Construction

[0039] The preparation method of the e-liquid base provided by the present disclosure includes the following steps:

[0040] Step (1): Prepare solvent.

[0041] During specific implementation, the solvent can be prepared according to the formula of 30-60 parts of glycerin, 1-60 parts of propylene glycol and 1-10 parts of water.

[0042] Step (2): Add the anti-greasy composition into the solvent, stir at 45°C-55°C until completely dissolved, and obtain the vape oil base.

[0043] During specific implementation, an appropriate proportion of nicotine, organic acid and tobacco polyphenols can be added to the solvent, and stirred in a water bath at 45°C-55°C until the grease-reducing composition is completely dissolved in the solvent, so that the nicotine oil base appears Clear and transparent.

[0044] Further, the temperature in step (2) is 50°C.

[0045] The e-cigarette oil formula provided in the present disclosure includes essence and the e-liquid base of the present disclo...

Embodiment 1

[0056] Mix glycerin, propylene glycol and water in a ratio of 45:50:5. Weigh 3.5g of nicotine, 3g of lactic acid (the molar ratio of nicotine to lactic acid is 1:1.54), 0.1g of chlorogenic acid, 0.060g of kaempferol-3-rutinoside, and 0.002g of scopoletin, and add them to 90.4g of solvent , and stirred at 50°C until clear and transparent. Finally, add 3g of essence and continue stirring for 5 minutes to obtain e-liquid sample S1.

Embodiment 2

[0058] Mix glycerin, propylene glycol and water in a ratio of 47:47:6 evenly. Weigh 4.0g of nicotine, 4.5g of benzoic acid (the molar ratio of nicotine and benzoic acid is 1:1.49), 0.050g of chlorogenic acid, 0.050g of rutin, and 0.001g of scopoletin, add 89.9g of solvent, and Stir at 50°C until clear and transparent. Finally, 1.5g of essence was added, and the stirring was continued for 5 minutes to obtain the e-liquid sample S2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com