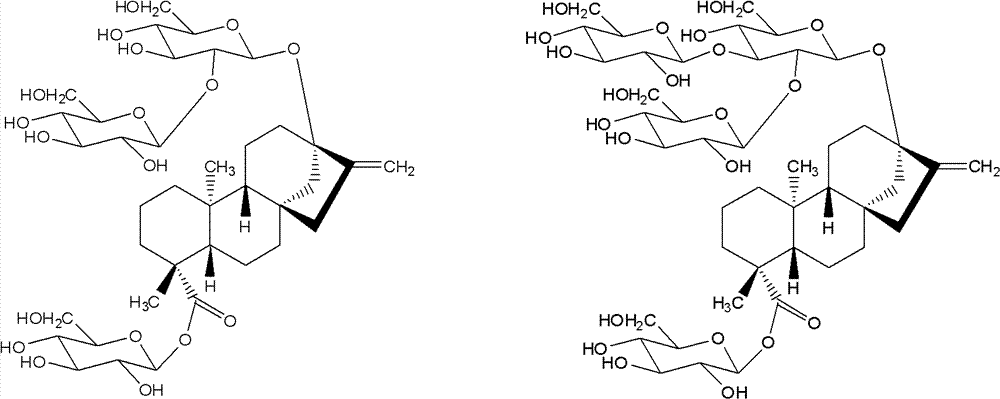

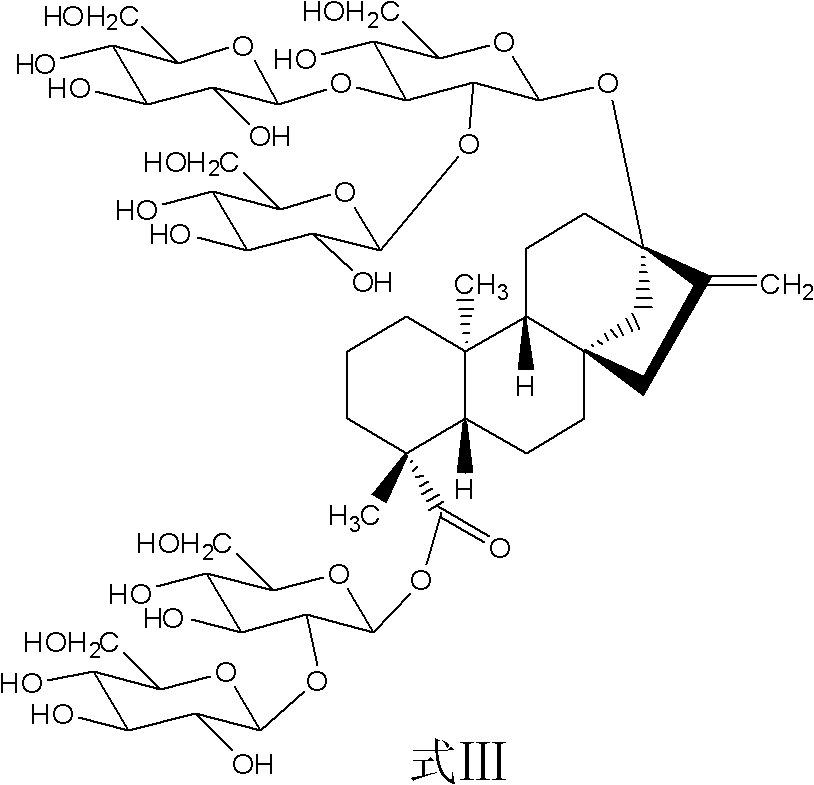

Composite sweeting agent and preparation method thereof, and method for improving taste of stevia glycoside sweeting agents

A compound sweetener and stevioside technology, which is applied in the field of improving the taste and flavor of stevioside natural sweeteners, and can solve the problem of pure natural energylessness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

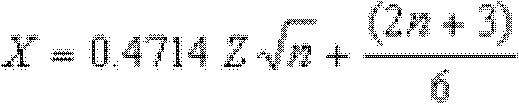

[0036] Embodiment Method principle: the following embodiment is to provide a group of three samples to the assessor at the same time, two of which are identical, and the assessor picks out a single sample.

[0037] Equipment: The person in charge of the inspection selects the equipment according to the nature of the product and the number of samples. The equipment used should not affect the test results. Priority should be given to using standardized equipment that meets inspection needs.

[0038] Sampling: Sampling shall be carried out according to the sampling standard of the inspected product. In the absence of such standards or when sampling standards are not fully applicable, the sampling method is to be agreed upon between the parties concerned.

[0039] Environment: It should meet the requirements of GB 10220.

[0040] Evaluator conditions: should comply with the conditions stipulated in GB 10220, all evaluators should have the same qualifications and testing capabil...

Embodiment 1

[0063] Example 1 The ratio of rebaudioside D to stevioside 1:9-9:1 (w / w) compared with the mouthfeel of sucrose

[0064] Prepare samples rebaudioside D (>90%), stevioside (>95%), rebaudioside D-stevioside (1:9, w / w), rebaudioside D-stevioside (9: 1, w / w), rebaudioside D-stevioside (3:7, w / w), and the comparison sample was sucrose. The sample and the comparison sample were made into aqueous solutions with the same sweetness, and then the experiment was carried out according to the requirements of the above sensory analysis method. Effective evaluators: 138 junior evaluators, allowed to answer "no difference". The results are shown in Table 1.

[0065] Table 1 The experimental results of the ratio of rebaudioside D and stevioside 1:9-9:1 (w / w) and the taste of sucrose

[0066]

[0067] From the above data, we can see that when the proportioning range (w / w) of high-purity rebaudioside D (>90%) and high-purity stevioside (>95%) is 1:9-9:1, its Taste is similar to sucrose.

Embodiment 2

[0068] Example 2 The ratio of rebaudioside D to stevioside 3:7-7:3 (w / w) compared with the mouthfeel of sucrose

[0069] Prepare samples rebaudioside D (>90%), stevioside (>95%), rebaudioside D-stevioside (3:7, w / w), rebaudioside D-stevioside (7: 3, w / w), rebaudioside D-stevioside (4:6, w / w), and the comparison sample was sucrose. The sample and the comparison sample were made into aqueous solutions with the same sweetness, and then the experiment was carried out according to the requirements of the above sensory analysis method. Effective evaluators: 135 junior evaluators, allowed to answer "no difference". The results are shown in Table 2.

[0070] Table 2 The experimental results of the taste comparison between rebaudioside D and stevioside 3:7-7:3 (w / w) and sucrose

[0071]

[0072] From the above data, we can see that when the proportioning range (w / w) of high-purity rebaudioside D (>90%) and high-purity stevioside (>95%) is 3:7-7:3, its The mouthfeel is very simila...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com