Hypsizigus marmoreus factory solid strain production process

A technology of solid strains and production technology, which is applied in horticulture, mushroom cultivation, botanical equipment and methods, etc., and can solve the problems of unstable strain quality, limitations in the improvement of the vitality of jiji mushroom strains, and difficulty in controlling the production quality of strains, etc. problems, to achieve the effect of improving output quality, ensuring cultivation efficiency, and ensuring production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

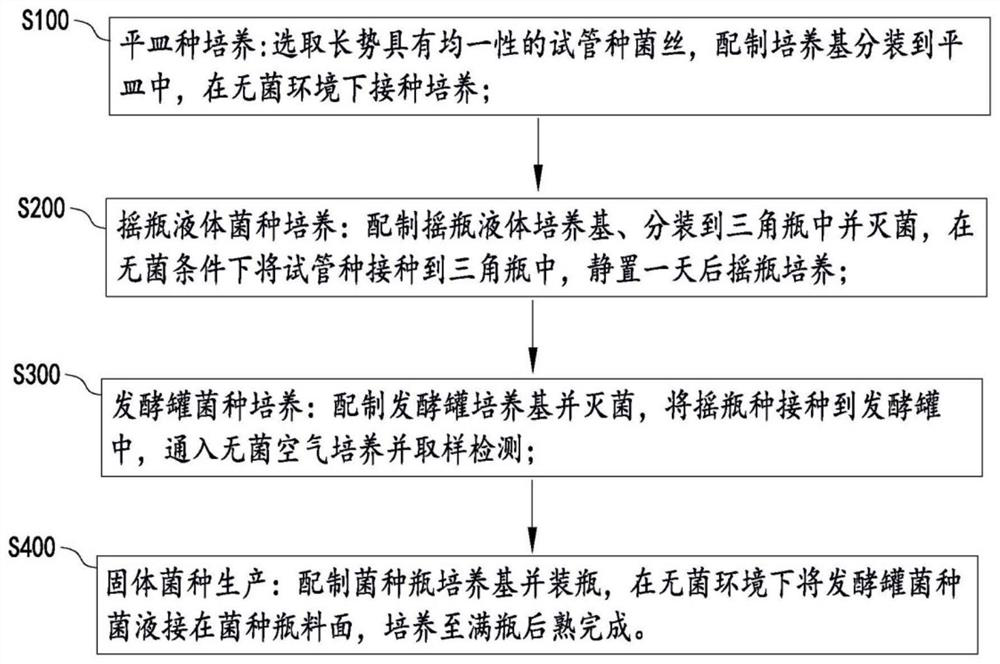

[0036] Such as figure 1 As shown, a kind of industrialized solid strain production process of shiji mushroom in a preferred embodiment of the present invention comprises the following steps:

[0037] S100, culturing on flat plates: the prepared culture medium is divided into flat plates, and the mycelium of test tube species with uniform growth is selected, and inoculated and cultivated in a sterile environment.

[0038] In this process, unqualified plate species such as poor growth, uneven growth, and bacterial infection are eliminated.

[0039] As a preferred solution, in step S100, the characteristics of the test-tube species mycelium with uniform growth are as follows:

[0040] The appearance is uniform, the hyphae are white and strong, the growth is neat, the culture medium has no drying shrinkage, and there are no spots, streaks or shadows except the inoculated spots when observed from the reverse side;

[0041] Uniform growth refers to the observation of the growth st...

Embodiment 2

[0095] This embodiment is basically the same as Example 1, the difference is that in step S400, the growth of mycelia in the cultivation bottle is observed, and it is required that the mycelia reach 1.2 cm from the shoulder of the bottle for 5 days, and mycelium germinates at the bottom of the cultivation bottle.

[0096] As a preferred solution, in step S400, observe the growth of the mycelia in the cultivation bottle, and it is required that the mycelia reach 2.8 cm below the bottle shoulder in 11 days, and the feeding height at the bottom of the cultivation bottle reaches 1.6 cm.

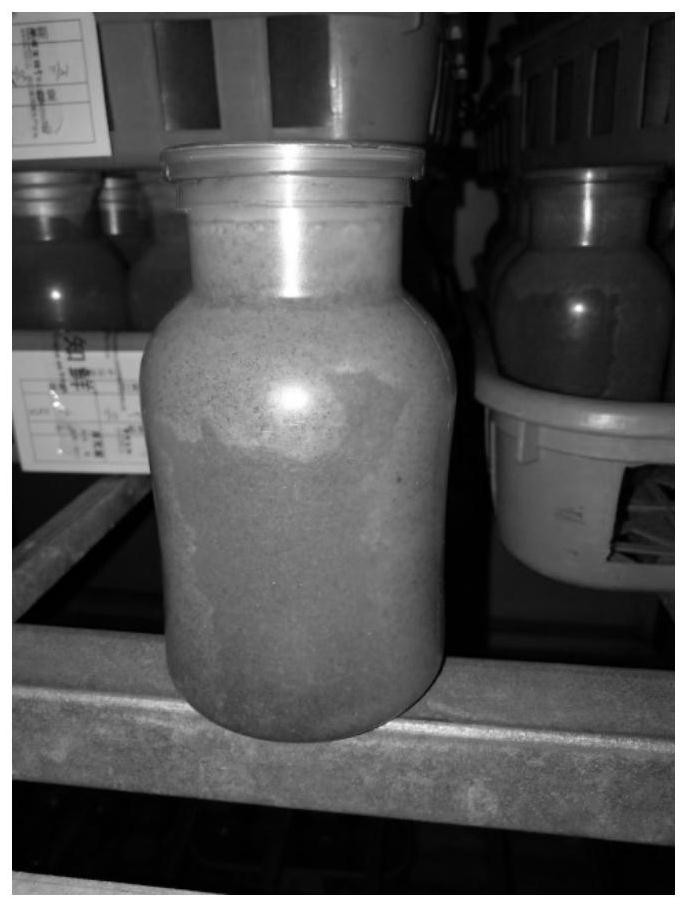

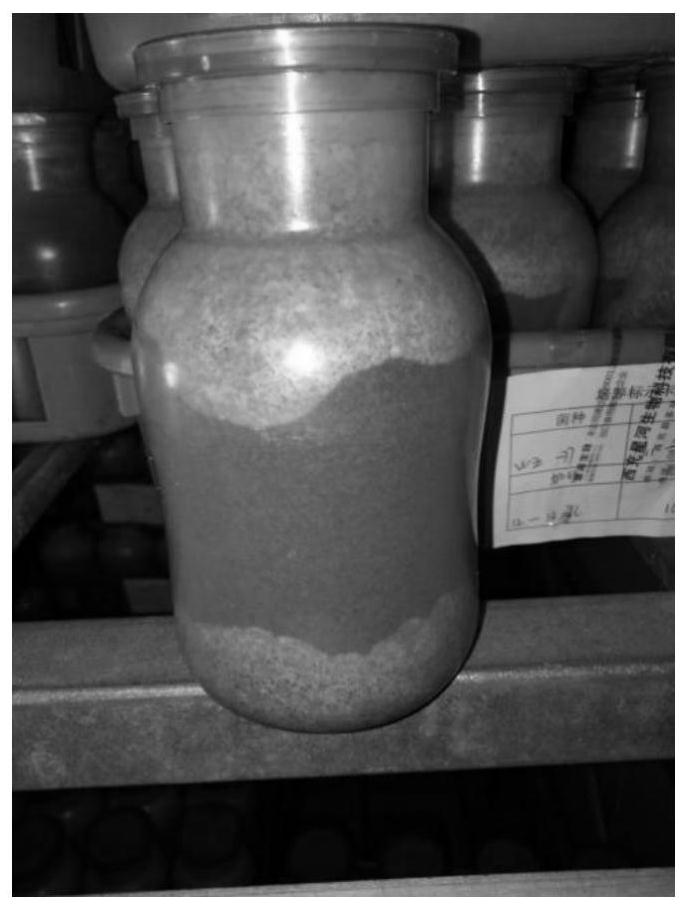

[0097]As a preferred solution, in step S400, in the cultivation bottle, the mycelia are required to reach through the wall in 18 days; when the bottle is completely full in 30 days, the local color change begins; in 37 days, 90% of the color change is completed: in 44 days, the bottle wall mycelium is thick and white .

Embodiment 3

[0099] This embodiment is basically the same as Example 1, the difference is that in step S400, the growth of mycelia in the cultivation bottle is observed, and it is required that the mycelia reach 1.5 cm from the shoulder of the bottle in 5 days, and mycelium germinates at the bottom of the cultivation bottle.

[0100] As a preferred solution, in step S400, observe the growth of the mycelium in the cultivation bottle, and it is required that the mycelia reach 3 cm below the shoulder of the bottle in 11 days, and the feeding height at the bottom of the cultivation bottle reaches 1.8 cm.

[0101] As a preferred solution, in step S400, the mycelium is required to reach through the wall in 18 days in the cultivation bottle; the full bottle is reached in 30 days, and the part starts to turn color; 90% of the color change is completed in 38 days; the bottle wall mycelium is thick white in 45 days .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com