Infrared detector and pixel based on CMOS process and preparation method thereof

An infrared detector and process technology, applied in the field of infrared detection, can solve the problems of low yield, low pixel scale, and low performance of infrared detectors, and achieve high yield, small chip area, and reduced process difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] In order to understand the above objects, features, and advantages of the present disclosure, the disclosure will be further described below. It should be noted that the features of the present disclosure may be combined with each other in the case of an unable conflict.

[0078] A lot of specific details are set forth in the following description to fully understand the present disclosure, but the present disclosure can also employ other different from the embodiments described herein; Not all embodiments.

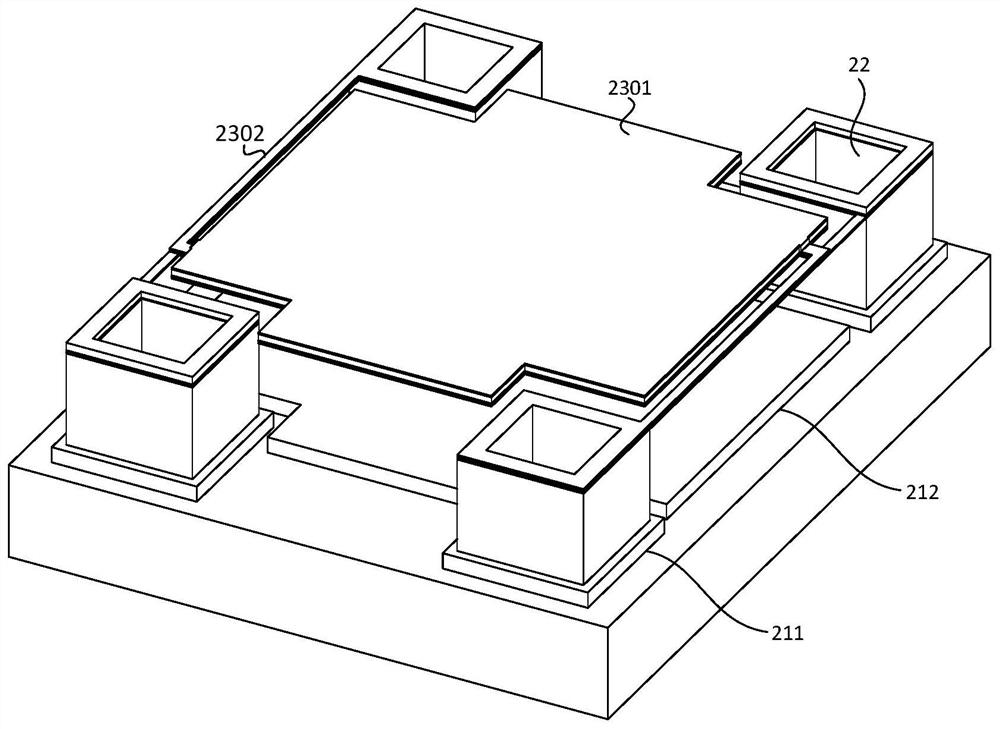

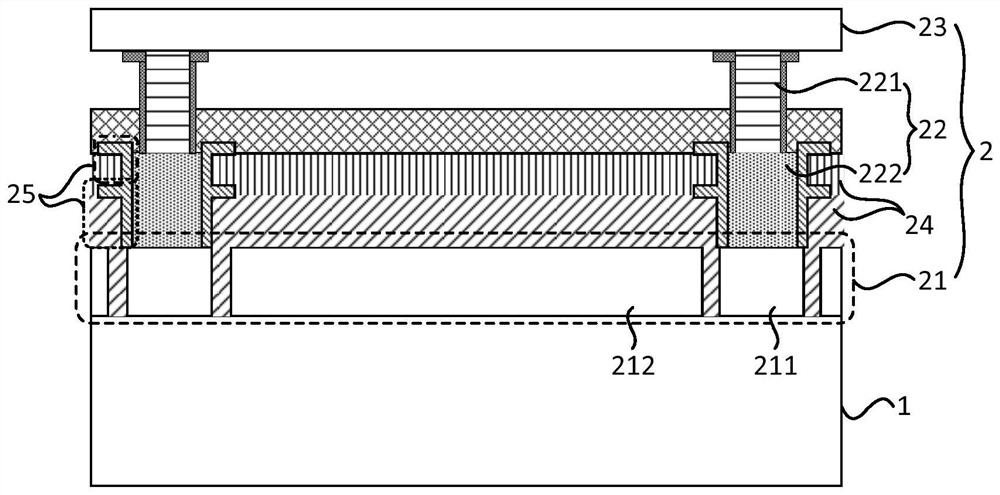

[0079] figure 1 A perspective view of an infrared detector cell for the embodiment of the present disclosure, figure 2 A cross-sectional structure of an infrared detector image element is a longitudinal cross-sectional structure, which is a longitudinal sectional structure. Refer figure 1 with figure 2 The infrared detector image includes: CMOS measuring circuit system 1 and CMOS infrared sensing structure 2 on which is electrically connected thereon, CMOS measuring c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com