Inner rotor brushless motor and manufacturing method thereof

An inner rotor and motor technology, applied in the field of inner rotor brushless motors, can solve problems such as loss of magnetic flux, reduction of mechanical strength of the iron core, deformation of the shape of the iron core, etc., and achieve the effect of increasing the degree of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

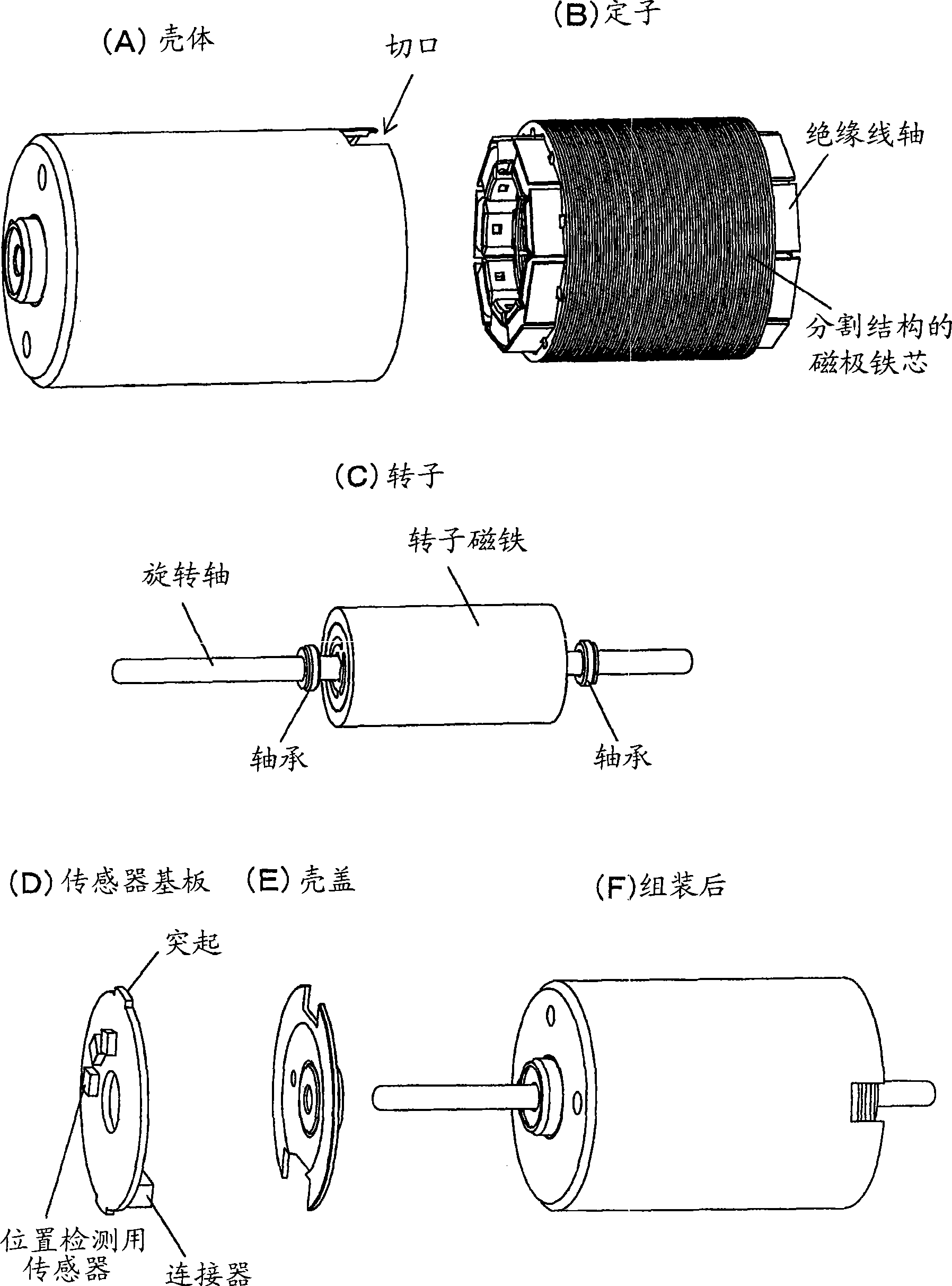

[0022] Hereinafter, the present invention will be described based on examples. figure 1 It is an exploded perspective view of an inner rotor brushless DC motor embodying the present invention. figure 1 (A) represents the casing, (B) represents the stator, (C) represents the rotor, (D) represents the sensor substrate, (E) represents the case cover, and (F) represents the overall assembled structure. figure 2 is a cross-sectional view of the overall structure, figure 2 (A) and (B) in (A) and (B) are figures which are respectively cut with mutually different orthogonal planes.

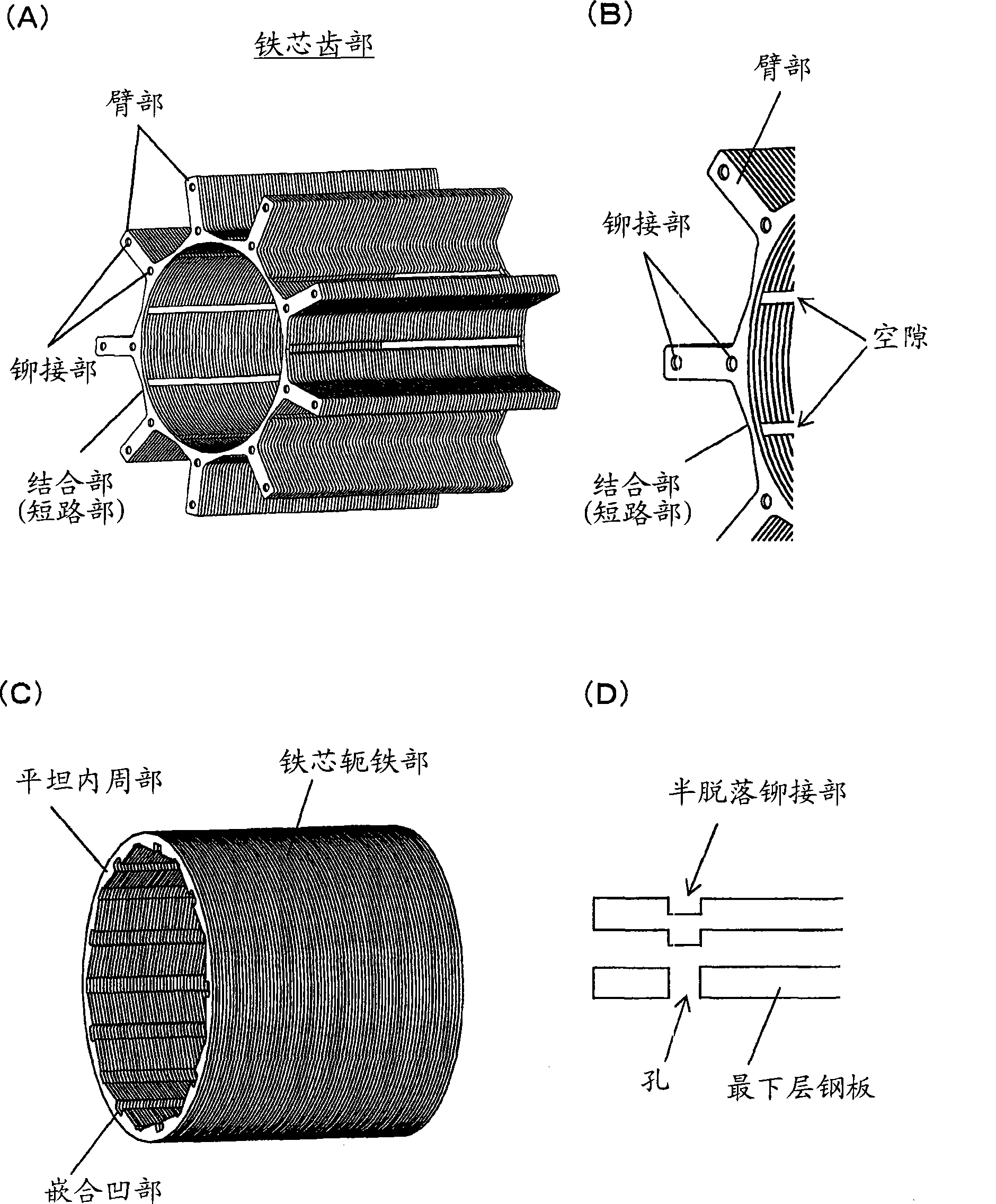

[0023] The motor case is composed of a bottomed hollow cylindrical case made of metal or resin, and a case cover made of metal or resin. The cover is fitted over a stepped portion provided on the inner peripheral portion of the opening of the case. A stator consisting of a pole core and a winding is fixed on the inner wall of the cylindrical housing. The pole core is a split structure divided into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com