Multi-tolerance saccharomyces cerevisiae strain and construction method and application thereof

A Saccharomyces cerevisiae strain and tolerance technology, applied in the field of bioengineering, can solve the problems of stress resistance and single tolerance, achieve the effects of improved tolerance, good industrial application potential, and improved ethanol resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0114] Ethanol glucose co-fermentation:

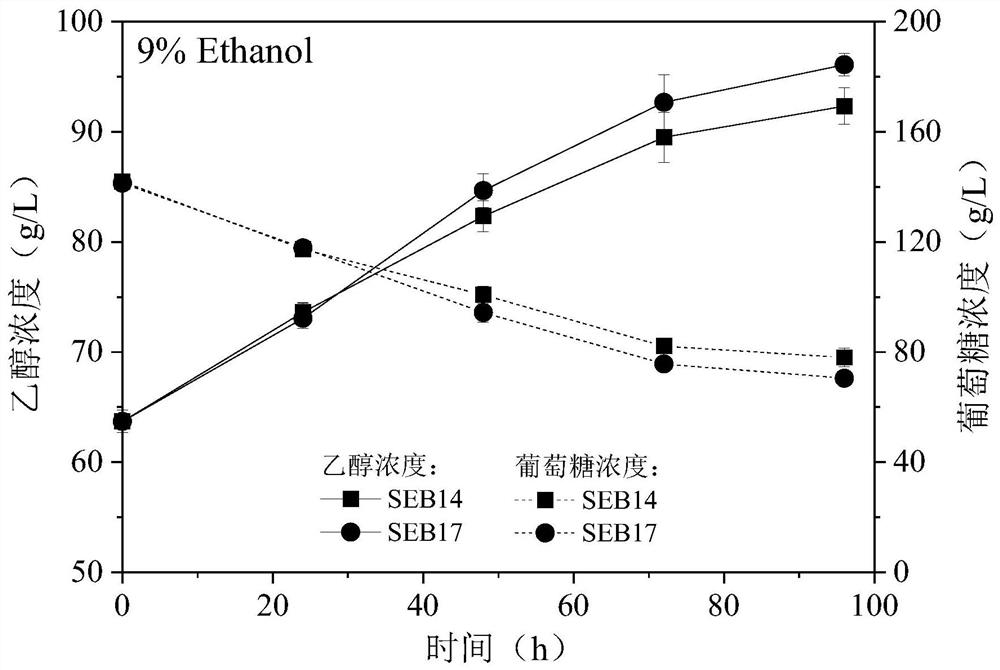

[0115] Using the industrial Saccharomyces cerevisiae strain SEB14 as the host and highly expressing the gene ENA5, an excellent multi-tolerant strain SEB17 was obtained. After co-fermentation with 9% (v / v) initial ethanol and 141.95g / L glucose for 96h, it produced 32.39±1.02g / L ethanol, which was 13.09% (28.64±1.66g / L) higher than that of strain SEB14. Meanwhile, after 24 hours of fermentation, the fermentation rate of SEB17 was significantly higher than that of SEB14. The results indicated that the highly expressed gene ENA5 could significantly improve the ethanol tolerance of SEB14, as shown in Table 11 and figure 1 shown.

[0116] Table 11 96h results comparison of bacterial strain fermentation under the mixed condition of 9% (v / v) ethanol and 141g / L glucose

[0117]

[0118] Note: The same letter in the same column means no significant difference, different letters mean significant difference, P<0.05(t-test). 9% (v / v) ethano...

Embodiment 2

[0120] High temperature fermentation:

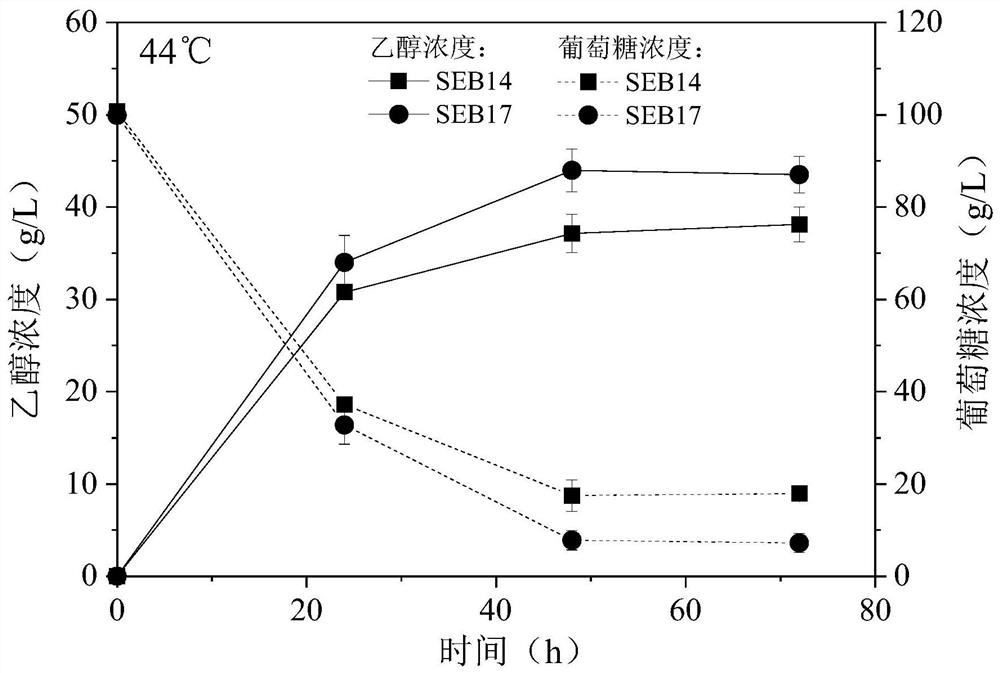

[0121] This example explores the high temperature tolerance of strain SEB17. Under the fermentation conditions of 44°C and 100.65g / L glucose, the ethanol concentration of strain SEB17 was significantly (P figure 2 ). After 72 hours of fermentation, the ethanol concentration and glucose concentration of SEB17 were 43.52±1.17g / L and 7.21±2.03g / L, respectively. Compared with SEB14, it increased by 14.17% and decreased by 59.74% (Table 12). This result indicated that high expression of ENA5 could significantly improve the high temperature tolerance of strain SEB14.

[0122] Table 12 Comparison of strains fermented for 72 hours at 44°C

[0123]

[0124] Note: The same letter in the same column means no significant difference, different letters mean significant difference, P<0.05(t-test). SEB17:

[0125] The strain SEB14 highly expressed the gene ENA5.

Embodiment 3

[0127] High temperature ethanol co-fermentation:

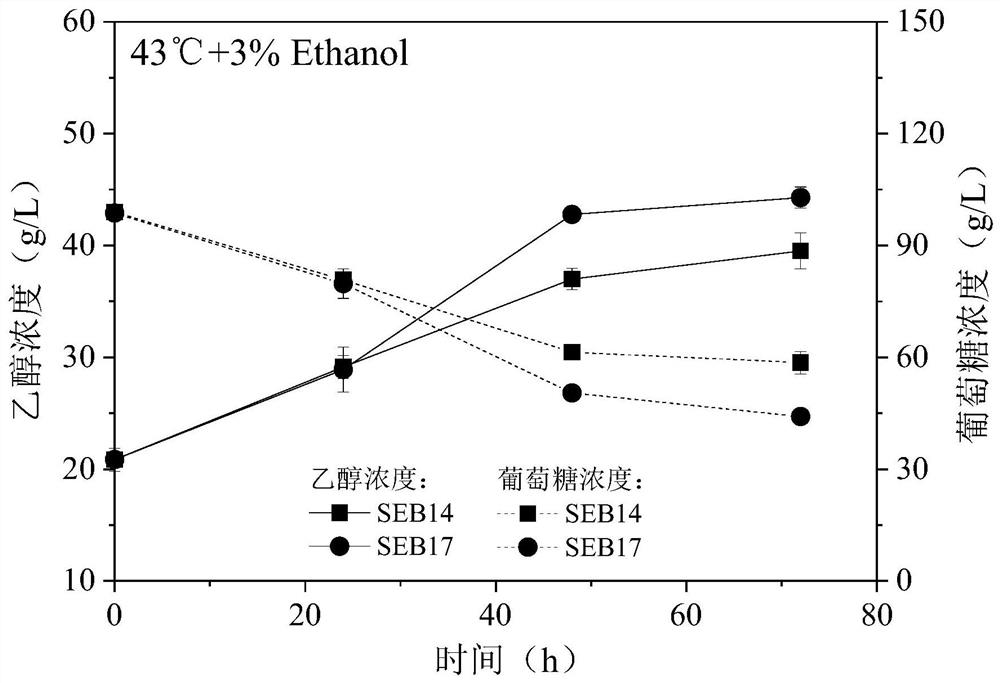

[0128] In the late stage of SSF fermentation, yeast cells must tolerate both high temperature and gradually increasing ethanol concentration. In this example, it was found that SEB17 also exhibited better fermentation performance than the starting strain SEB14 under the co-fermentation conditions of initial addition of 3% ethanol and high temperature of 43°C. At the end of the fermentation, its ethanol production concentration (23.43 ± 0.95g / L) increased by 20.36% compared with the starting strain SEB14 (18.66 ± 1.62g / L), indicating that the strain SEB17 can well tolerate the dual stress of high temperature and ethanol, The highly expressed gene ENA5 is crucial for improving the tolerance of strain SEB14 to the dual stress of high temperature and ethanol ( image 3 , Table 13).

[0129] Table 13 Comparison of results of 72h fermentation of strains with initial addition of 3% ethanol and 43°C

[0130]

[0131] Note: The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com