Atomizer capable of exhausting and preventing oil leakage and electronic cigarette

An atomizer and oil leakage technology, applied in the field of electronic cigarettes, can solve the problems of insufficient oil supply, slow oil intake of the atomizer, burning out the heating core, etc., and achieve the effect of solving the slow oil intake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

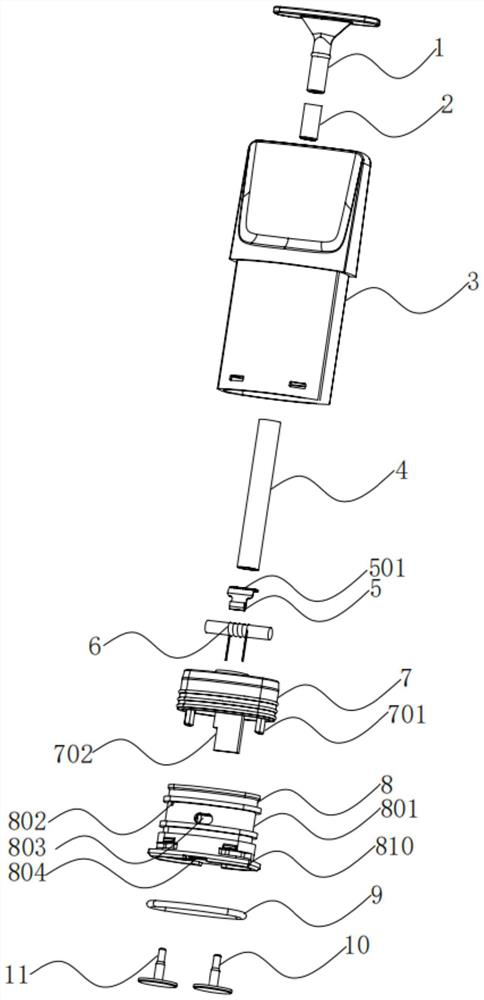

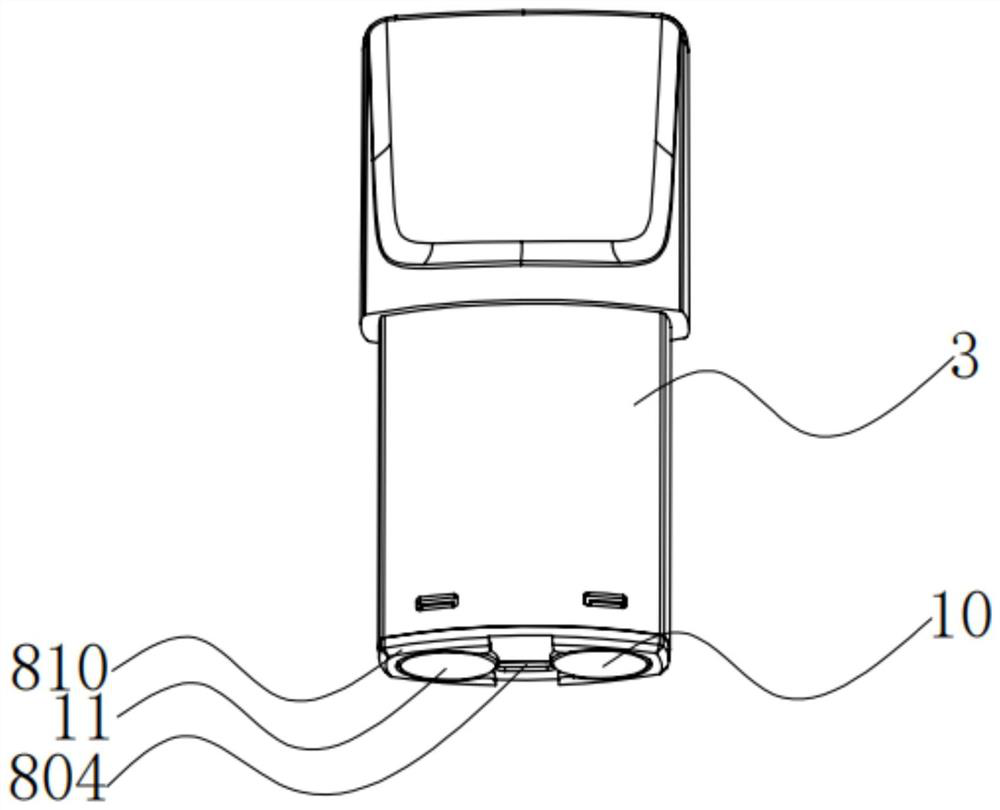

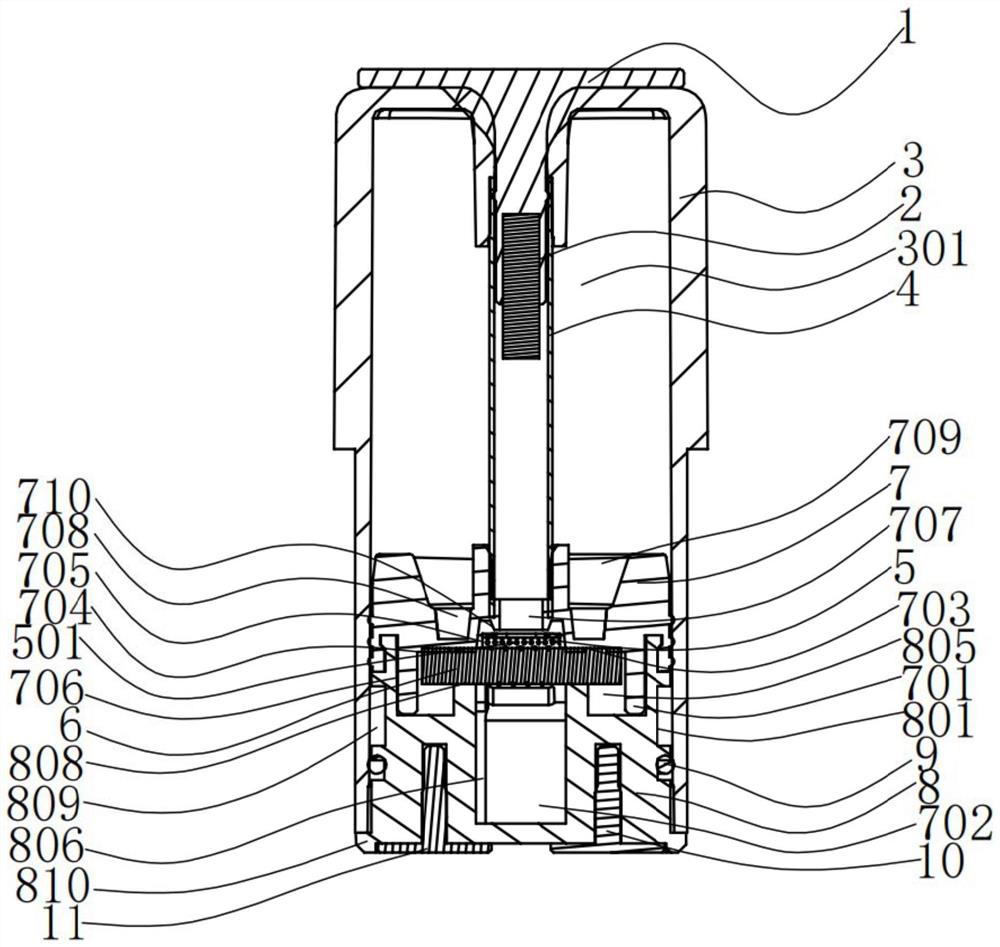

[0068] Such as Figure 1-7, The atomizer for exhaust and oil leakage prevention of this embodiment includes: suction nozzle plug 1, oil-absorbing cotton 2, oil storage bin body 3, smoke guide pipe 4, oil retaining member 5, heating core 6, oil sealing member 7, Air guide seat 8, sealing member 9, first conductive electrode 10, second conductive electrode 11, wherein the top of the oil storage bin body 3 is provided with a smoking port 302 for smoking, and the upper end of the smoke guide pipe 303 is inserted into the smoking port 302 to communicate with the smoking port. The port 302 is connected, and the oil sealing member 7 is installed in the oil storage bin body 3 for sealing the oil storage chamber 301. Two first grooves 709 are formed on the top of the oil sealing member 7, and each first groove 709 is connected with the oil storage chamber. The oil chamber 301 communicates for oil conduction, and the bottom wall of each first groove 709 is provided with an oil inlet hol...

Embodiment 2

[0072] Such as Figure 10-13 , The atomizer for exhaust and oil leakage prevention of this embodiment includes: suction nozzle plug 1, oil-absorbing cotton 2, oil storage bin body 3, smoke guide pipe 4, oil retaining member 5, heating core 6, oil sealing member 7, Air guide seat 8, sealing member 9, first conductive electrode 10, second conductive electrode 11, wherein the top of the oil storage bin body 3 is provided with a smoking port 302 for smoking, and the upper end of the smoke guide pipe 303 is inserted into the smoking port 302 to communicate with the smoking port. The port 302 is connected, and the oil sealing member 7 is installed in the oil storage bin body 3 for sealing the oil storage chamber 301. Two first grooves 709 are formed on the top of the oil sealing member 7, and each first groove 709 is connected with the oil storage chamber. The oil chamber 301 communicates for oil conduction, and the bottom wall of each first groove 709 is provided with an oil inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com