A sealing method for external protection of gear grinding machine

A technology for external protection and gear grinding machines, which is applied in the direction of gear cutting machines, components with teeth, gear teeth, etc. It can solve the problems of oil leakage at the joints of each sub-unit of the external protection of machine tools, no professional research, and stoppages, etc., to achieve improvement The operating environment of the workshop, the structure is safe and reliable, and the effect of solving the oil leakage of the external protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

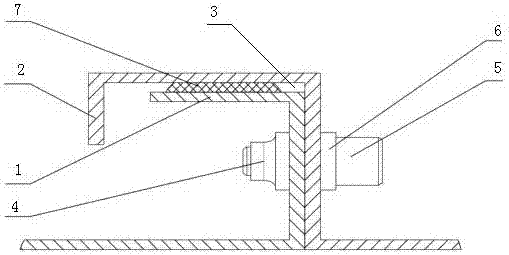

[0011] Below according to the attached figure 1 The present invention is further analyzed: as figure 1 As shown, a sealing method for the external protection of the gear grinding machine, the first sheet metal part 1 and the second sheet metal part 2 are fitted together through a half-back structure, and the inner side of the first sheet metal part 1 Weld the high-strength M6T nut 4, the M6*12 inner hexagon nut 5 is matched with the M6T nut on the second sheet metal part 2, and add an anti-horizontal pad 6 on the connection side of the second sheet metal part 2 to play a role. The overall waterproof and oil mist-proof effect; reserve a gap 3 of 2mm in the horizontal direction of the two sheet metal parts, install a semi-spherical rubber sealing strip 7 in the reserved gap 3, and put a strong glue on the back during the installation process The hemispherical rubber sealing strip 7 sticks to the horizontal mating surface of the first sheet metal part 1, and the hemispherical ru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com