Preparation of coralline algae enzymatic hydrolysate and application of coralline algae enzymatic hydrolysate in cigarettes

A technology of coral algae enzymolysis solution and enzymolysis product, which is applied in the fields of tobacco preparation, application, tobacco, etc., can solve the problems of low utilization rate of development and low added value, etc., so as to improve sensory comfort, improve moisturizing, Improve the effect of sucking food quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

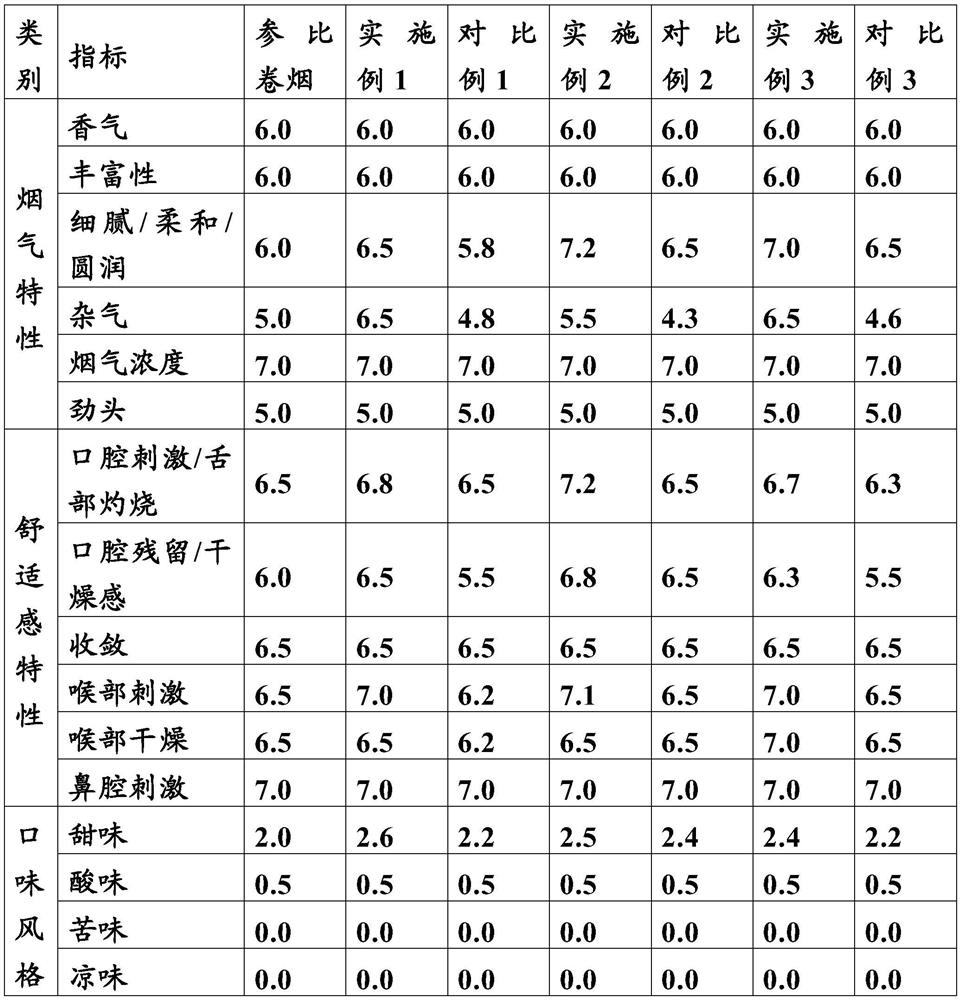

Examples

preparation example Construction

[0056] The purpose of the present invention can be achieved through the following technical solutions: the preparation method of coralline algae enzymatic hydrolyzate of the present invention comprises the following steps:

[0057] (1) Cleaning and removing impurities: Coral algae are first washed with water to remove impurities, on the one hand to remove impurities, and on the other hand to remove the salt on the surface of coral algae;

[0058] (2) Soaking and desalination: Take a certain weight of cleaned coral algae, add 3-20 times the weight of water, soak for 3-40 hours at a temperature of 10-50°C, and soak for a long time to further remove residual coral algae internal salinity;

[0059] (3) Drying and crushing: after cleaning and soaking, the coralline algae is dried at a temperature of 50-90°C until the moisture content is below 10%, and then crushed to 30-100 mesh to obtain dry coralline algae powder;

[0060] (4) Composite enzymatic hydrolysis: take a certain weigh...

Embodiment 1

[0081] After the fresh coralline algae are washed and removed, add 5 times the amount of water and soak for 20 hours at 25°C; take out the soaked and desalted coralline algae and dry them in an oven at 70°C for 15 hours, and the dried coral After crushing the algae, pass through a 50-mesh sieve to obtain dry powder of coralline algae; take 20kg of dry powder of coralline algae, add 800kg of water, 800g of pectinase and 600g of cellulase, adjust the pH value to 5.5, and enzyme at 55°C under continuous stirring conditions hydrolysis treatment for 4 hours to obtain coralline algae enzymatic solution; coralline algae enzymatic solution was further heated at 85°C under continuous stirring for 2.5 hours to inactivate pectinase and cellulase in the enzymatic solution; The solution is further separated by a tubular high-speed centrifuge to achieve solid-liquid separation, and the solid impurities in the enzymolysis solution are removed at a speed of 14,000 rpm; a tubular ceramic membra...

Embodiment 2

[0085] After the salted coralline algae are washed and removed, add 10 times of water and soak at 30°C for 15 hours; take out the soaked and desalted coralline algae and dry them in an oven at 80°C for 8 hours. The coralline algae is crushed and passed through a 80-mesh sieve to obtain dry coralline algae powder; take 40kg of coralline algae dry powder, add 1000kg of water, 1kg of xylanase and 500g of amylase, adjust its pH value to 6.5, and dry it at 50°C under continuous stirring conditions. The enzymatic hydrolysis of coralline algae was treated for 3 hours to obtain the enzymatic hydrolysis of coralline algae; the enzymatic hydrolysis of coralline algae was further heated at 80°C for 3 hours under continuous stirring to inactivate xylanase and amylase in the enzymatic hydrolysis; The enzymolysis solution is further separated by a tubular high-speed centrifuge to achieve solid-liquid separation, and the solid impurities in the enzymolysis solution are removed at a speed of 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Membrane pore size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com