Device for improving pork quality by adopting nitric oxide gas fumigation and method using device

A technology for nitric oxide and pork quality, applied to gas-containing food ingredients, the use of chemicals to preserve meat/fish, and the function of food ingredients, etc., to achieve the effects of reduced storage loss, low cost, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

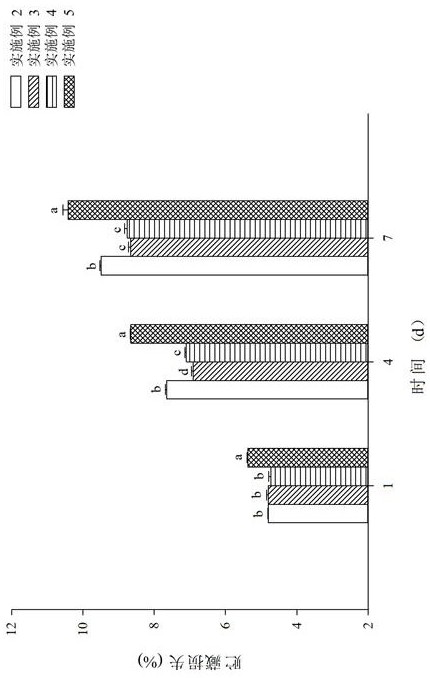

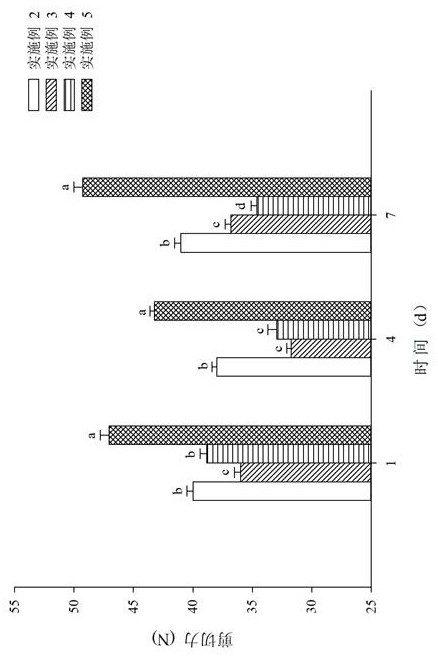

Examples

Embodiment 1

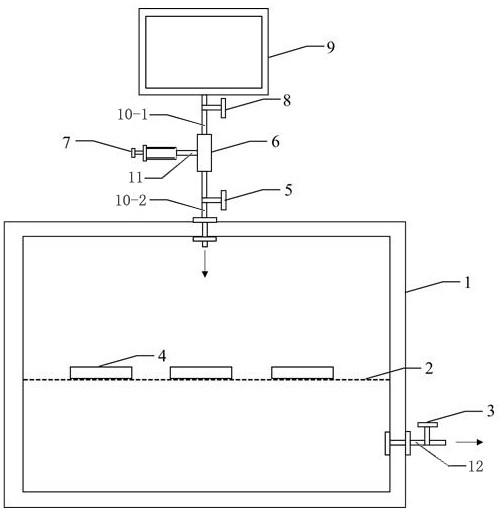

[0045] Embodiment 1: Adopt the device that adopts nitric oxide gas fumigation to improve pork quality;

[0046] 1), open the airtight door on the fumigation container 1, place the pork slices 4 flatly above the plastic mesh plate 2 in the fumigation container 1, and then close the airtight door;

[0047] 2), Nitrogen flushing: Open the nitrogen cylinder, the nitrogen concentration in the cylinder is 99.9%, turn the nitrogen pressure reducing valve, adjust the nitrogen flow rate through the rotameter, pass the nitrogen into the aluminum foil 9 and the syringe 7 through the nitrogen pipe; adjust the one-way The valve 8, the three-way valve 6, and the air intake valve 5 make the aluminum foil bag 9 and the syringe 7 communicate with the fumigation container 1, and open the exhaust valve 3 on the fumigation container 1; the nitrogen in the aluminum foil bag 9 passes through the first pipe 10-1 , three-way valve 6, second pipe 10-2, air intake valve 5 flow into the fumigation conta...

Embodiment 2

[0053] Embodiment 2: the control treatment of fresh pork fumigated without nitric oxide gas;

[0054] Step 1), pork pre-treatment: Remove the visible fascia and fat from the longissimus muscle of the back of the fresh pig within 6 hours after slaughter, and trim it to 5×5×2cm 3 (weight 60g) meat slices (pork slices), the meat slices are placed flatly above the plastic net inside the fumigation container.

[0055] Nitrogen flushing: open the nitrogen cylinder, turn the nitrogen pressure reducing valve, adjust the nitrogen flow rate through the rotameter, pass the nitrogen into the aluminum foil 9 and the syringe 7 through the nitrogen pipe; adjust the one-way valve 8, the three-way valve 6, and the intake valve 5. Make the aluminum foil bag 9 and the syringe 7 communicate with the fumigation container 1, and open the exhaust valve 3 on the fumigation container 1; the nitrogen in the aluminum foil bag 9 passes through the first pipe 10-1, the three-way valve 6, and the second pi...

Embodiment 3

[0058] Example 3: Fumigate fresh pork with nitric oxide gas at a concentration of 40 μL / L;

[0059] Step 1), pork pre-treatment: Remove the visible fascia and fat from the longissimus muscle of the back of the fresh pig within 6 hours after slaughter, and trim it to 5×5×2cm 3 (weight 60g) meat slices (pork slices), the meat slices are placed flatly above the plastic net inside the fumigation container.

[0060] Step 2), nitrogen flushing device: open the nitrogen cylinder, turn the nitrogen pressure reducing valve, adjust the nitrogen flow rate through the rotameter, and pass the nitrogen into the aluminum foil 9 and the syringe 7 through the nitrogen pipe; adjust the one-way valve 8 and the three-way valve 6. The air intake valve 5 makes the aluminum foil bag 9 and the syringe 7 communicate with the fumigation container 1, and the exhaust valve 3 on the fumigation container 1 is opened; the nitrogen in the aluminum foil bag 9 passes through the first pipe 10-1, the three-way ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com