Gas detector

A detector and gas detection technology, which is applied in the field of gas detectors, can solve the problems of inability to detect the whole air, troublesome disassembly and movement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

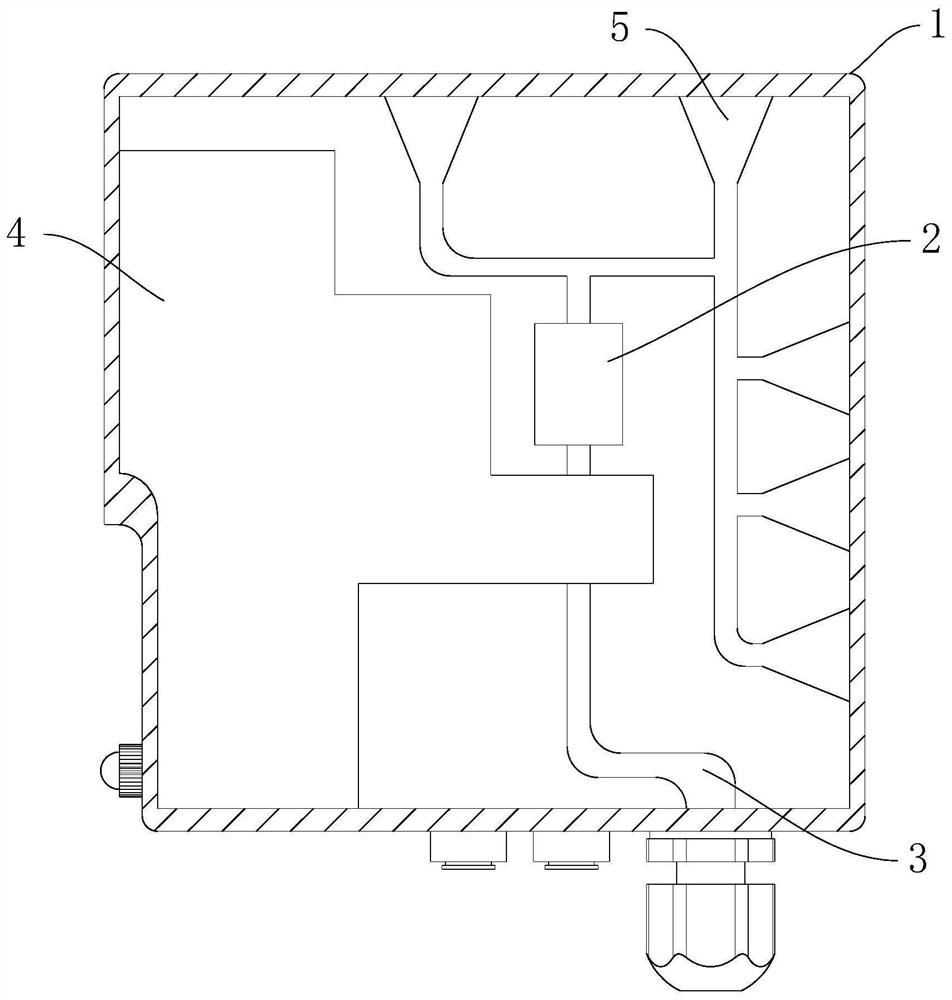

[0033] Please refer to figure 1 , figure 1 Shown is a gas detector provided by this embodiment, including a housing 1, an air pump 2, a gas detection device 4, an alarm, an air outlet pipe 3, a plurality of air inlet pipes 5, and any air inlet pipe 5 telescopic hose 6; one end of any intake pipe 5 is connected to the input end of the air pump 2, and the other end of any air intake pipe 5 is connected to the shell 1; the output end of the air pump 2, the gas detection device 4, the gas outlet The pipeline 3 communicates with the shell 1 in turn, the alarm is connected with the gas detection device 4 , and one end of the telescopic hose 6 is connected with the inner wall of the intake pipeline 5 .

[0034] In some embodiments of the present invention, the gas detector in the prior art can only detect the surrounding gas in a small range, and the larger space may not be able to fully detect the gas. This design adopts the telescopic hose 6, and when a large space needs to be de...

Embodiment 2

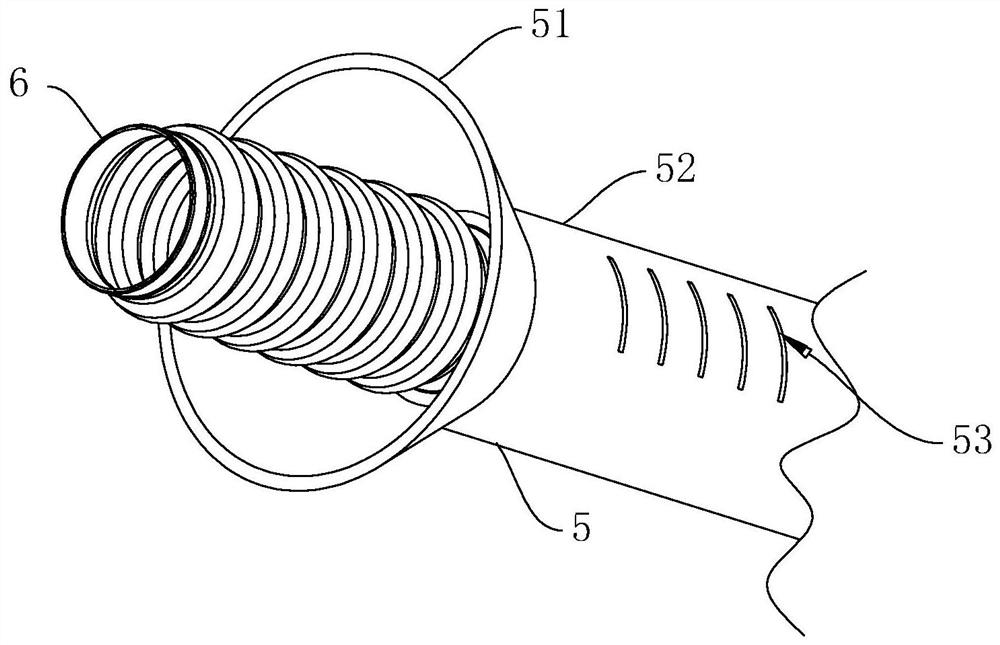

[0036] Please refer to figure 2 , the present embodiment proposes based on the technical solution of embodiment 1, any air intake pipe 5 comprises diameter-expanding section 51 and pipe main body 52, and casing 1, diameter-expanding section 51, pipe main body 52 and air pump 2 are connected in sequence; diameter-expanding section The diameter of 51 near the end of the shell 1 decreases gradually toward the end away from the shell 1 .

[0037] In some embodiments of the present invention, the purpose of setting the diameter-expanding section 51 is mainly that when the telescopic hose 6 shrinks into the intake pipe, if the intake pipe 5 adopts a pipe with the same diameter, the user needs to move the intake pipe 5 when shrinking. The pipe 5 is plugged into the air intake pipe 5 section by section, and it is easy to get knotted when plugging inward, which causes the user to pay attention when using it, thereby causing inconvenience to the user. Therefore, in this embodiment, the ...

Embodiment 3

[0041] Please refer to figure 2 , the present embodiment is proposed based on the technical solution of the second embodiment, and the upper side wall of the pipeline main body 52 is provided with a plurality of decompression holes 53 .

[0042] In some embodiments of the present invention, after such a gas detector is used for a long time, more dust and dirt will be accumulated in the intake pipe 5, the air pump 2 and the gas detection device 4, so that the intake air The area of the suction port of the pipeline 5 becomes smaller. In addition, the speed of air pump 2 transporting gas inward is inconvenient, which will easily cause the internal pressure of the intake pipe 5 to increase, causing the intake pipe 5 to expand and rupture, thereby making the detection inaccurate. Therefore, the present implementation adopts that a pressure relief hole 53 with a width of 0.05 mm is set on the pipeline main body 52. Thus, under normal air pressure, because the air intake pipeli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com