Bent pipe medium-frequency heating device with heating and cooling functions

A heating device and pipe bending technology, which is applied in the direction of quenching devices, forming tools, heat treatment furnaces, etc., can solve the problems of reduced mechanical properties of bent pipes, affecting material properties, insufficient hardening depth, etc., and achieves improved temperature control accuracy and wide application range. wide, fast heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

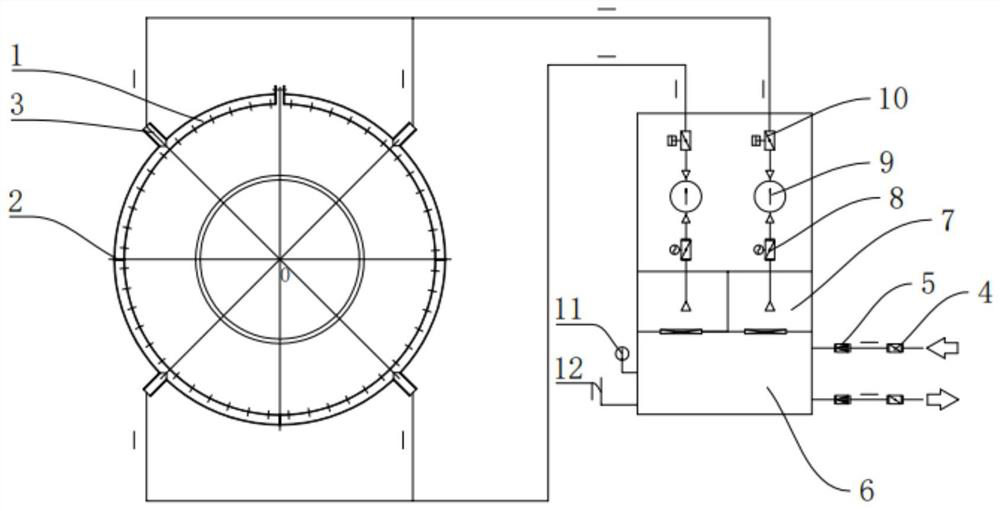

[0024] An intermediate frequency heating device with heating and cooling functions provided in this embodiment includes an induction coil 1, wherein the top of the induction coil 1 is an alternating positive and negative electrode, and the induction coil 1 is provided with spray holes at intervals. The high-frequency insulating ceramics 2 are connected with water inlet pipes 3 between adjacent high-frequency insulating ceramics 2, and each water inlet pipe 3 communicates with the corresponding high-frequency insulating ceramics 2, and the water inlet pipes 3 are connected with a spray system for water supply.

[0025] The high-frequency insulating ceramic 2 divides the induction coil 1 into corresponding cooling areas. When the induction coil 1 heats the steel pipe and performs the subsequent bending process, the spray system supplies water to the water inlet pipe 3, and the water flow is sprayed from the high-frequency insulating ceramic 2. The hole sprays out and acts on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com