Biodegradable high-performance particle material with ceramic texture and preparation method thereof

A biodegradable and high-performance technology, applied in the field of preparing biodegradable materials, can solve the problems of poor performance, insufficient toughness, and insufficient strength of degradable particle materials, and achieve good biodegradability, stability in use, and high tensile strength. and transmittance, good theoretical and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

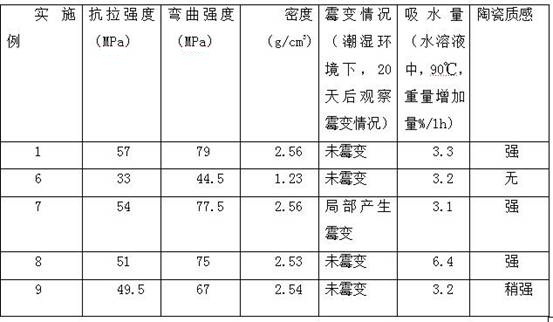

Examples

Embodiment 1

[0117] A naturally biodegradable high-performance particle material with a ceramic texture, made of the following raw materials in parts by weight: 90 parts of oxidatively modified high-amylose corn starch, 6.5 parts of 1-ethyl-3 methylimidazole acetate, po 3.5 parts of Loxamer, 8 parts of modified natural plant fiber, 15 parts of bio-fermented polybutylene succinate (PBS), 6 parts of nano-silica, 1 part of BASF's epoxy functionalized ADR chain extender , 0.7 part of maleic anhydride, 0.7 part of polyoxyethylene (PEO), 60 parts of modified high-density inorganic minerals; its preparation method may further comprise the steps:

[0118] 1) Weigh according to the weight ratio: 90 parts of oxidatively modified high-amylose corn starch, 6.5 parts of 1-ethyl-3 methylimidazole acetate, and 3.5 parts of poloxamer are added to the high-speed mixer together, and the top is sealed. Cover, after stirring for 5-12 minutes, at room temperature, ultrasonically oscillate for 30 minutes, the u...

Embodiment 2

[0123] A biodegradable high-performance particle material with a ceramic texture, made of the following raw materials in parts by weight: 90 parts of oxidatively modified high-amylose wheat starch, 5 parts of 1-ethyl-3 methylimidazole acetate, epoxy 5 parts of soybean oil, 5 parts of modified natural plant fiber, 3 parts of concentrated dry powder of wheat distiller's grains, 15 parts of biologically fermented polybutylene succinate (PBS), 6 parts of nano-silica, BASF's epoxy functional 1 part of Nadr chain extender, 0.7 part of maleic anhydride, 0.8 part of polyoxyethylene (PEO), 65 parts of modified high-density inorganic minerals; its preparation method comprises the following steps:

[0124] 1) Weigh according to the weight ratio: 90 parts of oxidized modified high-amylose wheat starch, 5 parts of 1-ethyl-3 methylimidazole acetate, and 5 parts of epoxy soybean oil are added to the high-speed mixer together, and the top is sealed. Cover and stir for 5-12 minutes, then ultra...

Embodiment 3

[0129] A biodegradable high-performance particle material with a ceramic texture, made of the following raw materials in parts by weight: 90 parts of oxidatively modified high-linear potato starch, 6 parts of lecithin, 4 parts of poloxamer, concentrated dry powder of sugarcane distiller's grains 4 parts, 4 parts of modified natural plant fiber, 15 parts of bio-fermented polybutylene succinate (PBS), 6 parts of nano-silica, 1 part of BASF's epoxy functionalized ADR chain extender, Malay 0.6 part of acid anhydride, 0.9 part of polyoxyethylene (PEO), 70 parts of modified high-density inorganic minerals; its preparation method may further comprise the steps:

[0130] 1) Weighing according to the weight ratio: 90 parts of oxidized modified high linear potato starch, 6 parts of lecithin, and 4 parts of poloxamer were added to the high-speed mixer, the top cover was sealed, and after stirring for 5-12 minutes, the At room temperature, ultrasonically oscillate for 30 minutes, the ultr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| service temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com